Method for producing gas sensor for detecting novel refrigerant HC-600a

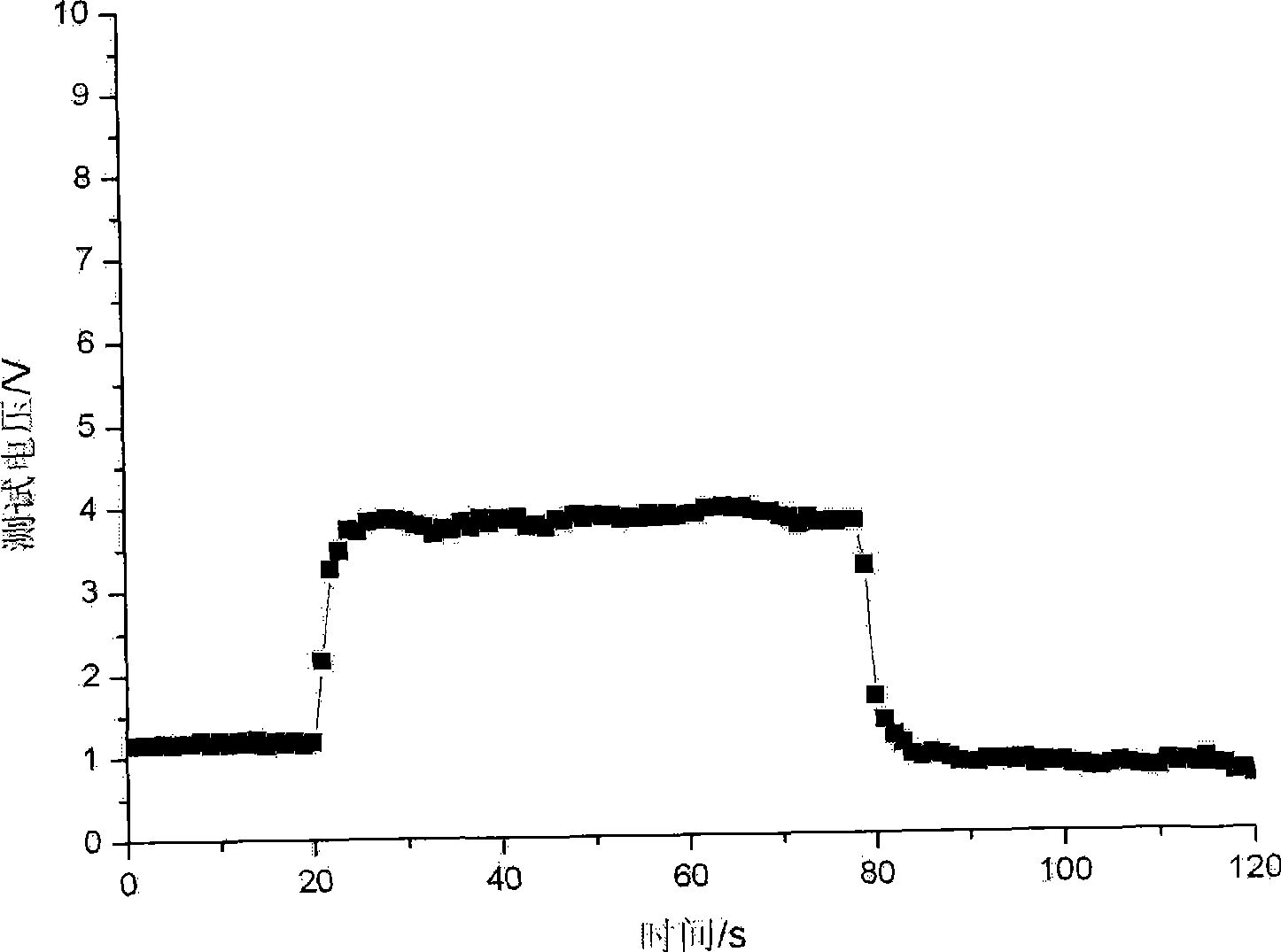

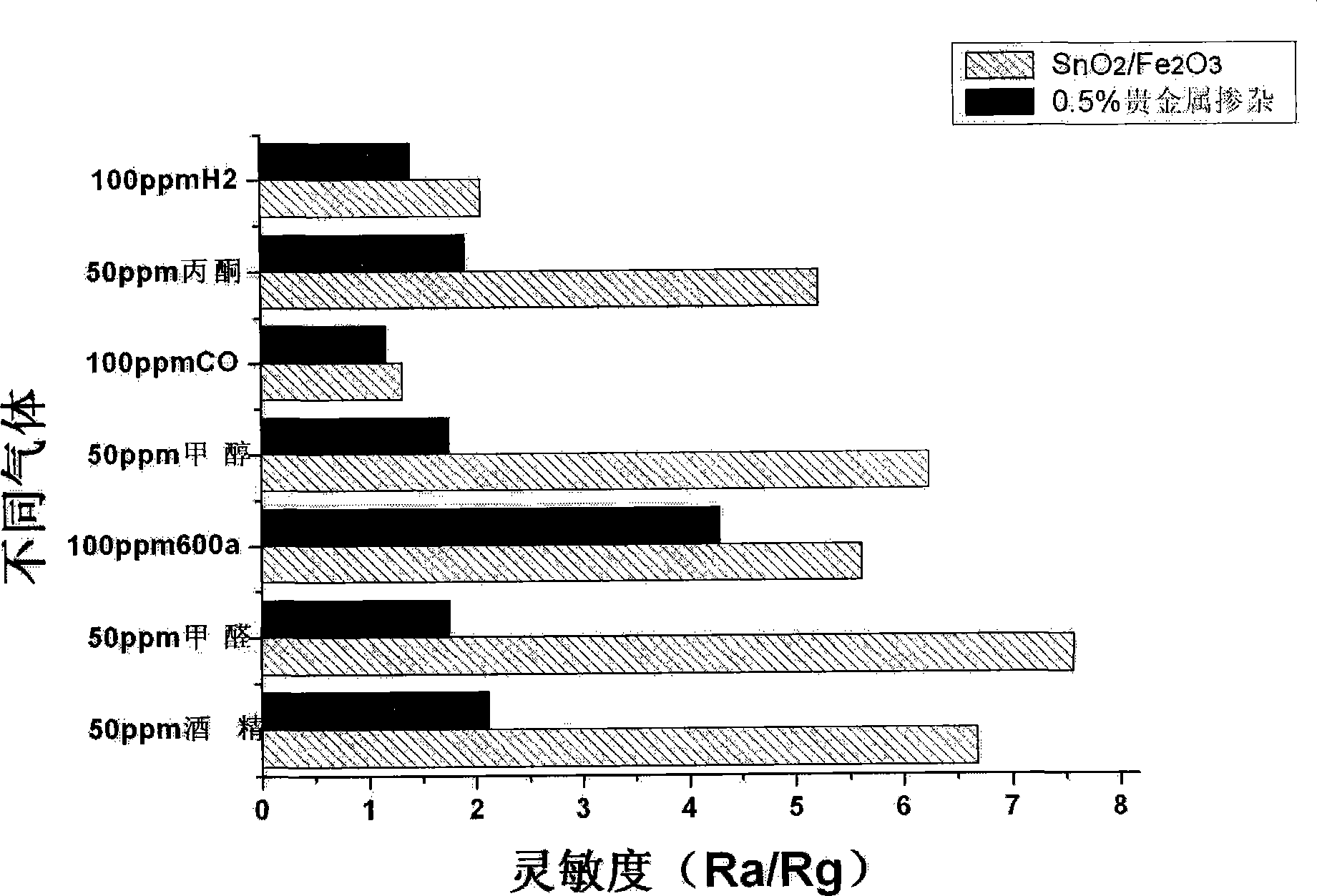

A technology of gas sensor and refrigerant gas, applied in measuring devices, material analysis through electromagnetic means, instruments, etc., can solve the problems of hidden dangers in production safety, low detection accuracy and selectivity, and achieve good stability and response recovery Short time, good selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: The preparation process and steps of the refrigerant HC-600a gas sensor in this embodiment are as follows:

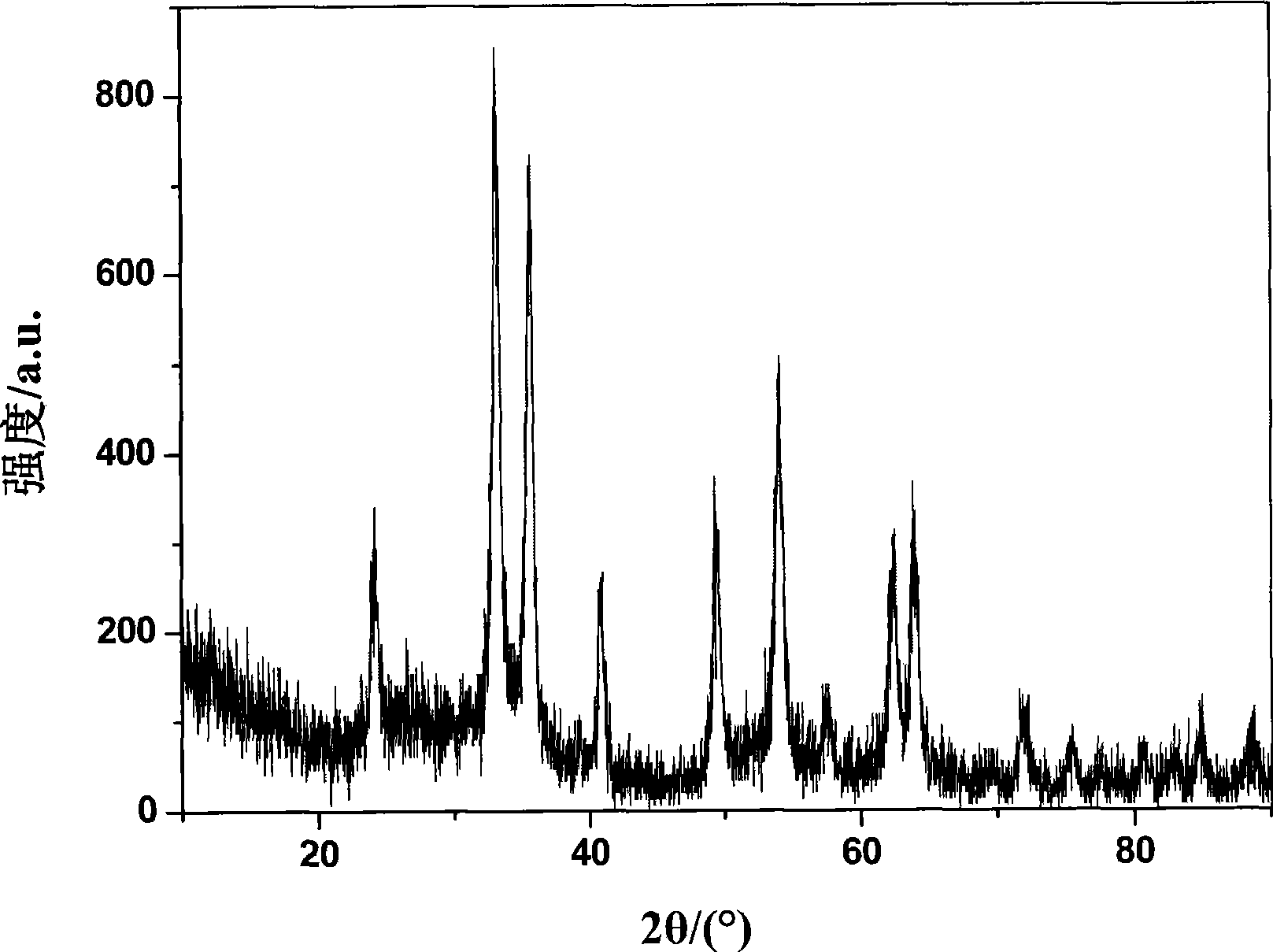

[0021] (1) Take 0.007g SnCl 4 ·5H 2 O was dissolved in 100ml deionized water under stirring conditions. Then add 0.54gFeCl 3 ·6H 2 O, stirred for 30min to obtain a khaki transparent solution A. Mix 20ml ammonia water and 20ml deionized water evenly to obtain solution B. Add solution B dropwise to solution A under stirring condition, and a reddish-brown precipitate can be obtained. Continue to titrate until pH=5 to stop the titration. The precipitate was separated by centrifugation and washed with deionized water to completely remove Cl - . Vacuum-dried at 50°C for 24 hours to obtain reddish-brown particles. After the particles are ground and refined, they are calcined at 650°C for 2 hours to obtain SnO 2 -Fe 2 o 3 Binary nanocomposite powder.

[0022] (2) Put the above materials in a mortar, and add HAuCl with a molar ratio of 1:1 drop ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| ignition point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com