Thermal storage defrosting or temperature controlling mixed working substance copious cooling throttle refrigeration system

A refrigeration system and mixed working medium technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

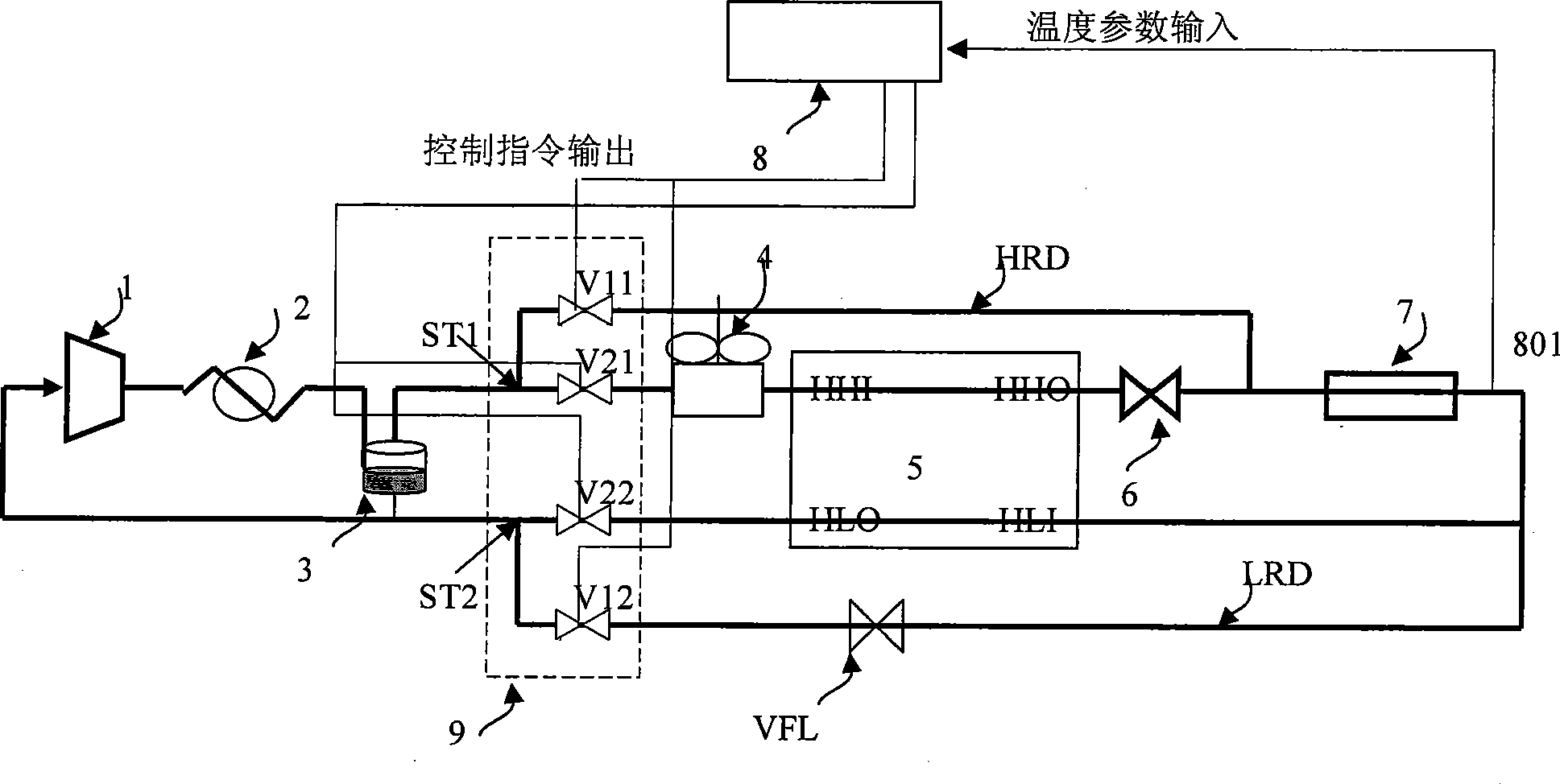

[0048] Embodiment 1: adopt figure 1 The refrigeration process and control system shown include compressor 1, heat accumulator 2, lubricating oil separator 3, aftercooler 4, recuperation heat exchanger unit 5, throttling refrigeration element 6, evaporator unit 7, and control unit 8 and a control execution unit group 9; the control execution unit group 9 includes a high-pressure three-way pipeline ST1, a high-pressure heating control valve V11, a high-pressure heating pipeline HRD, a high-pressure refrigeration control valve V21, a low-pressure three-way pipeline ST2, and a low-pressure heating control valve V12, low-pressure heating pipeline and low-pressure refrigeration control valve V22; see system connection figure 1 As shown, the refrigeration circuit C1 is composed of a compressor 1, a heat accumulator 2, a lubricating oil separator 3, an aftercooler 4, a recuperation heat exchanger unit 5, a throttling refrigeration element 6 and an evaporator unit 7; Compressor 1, hea...

Embodiment 2

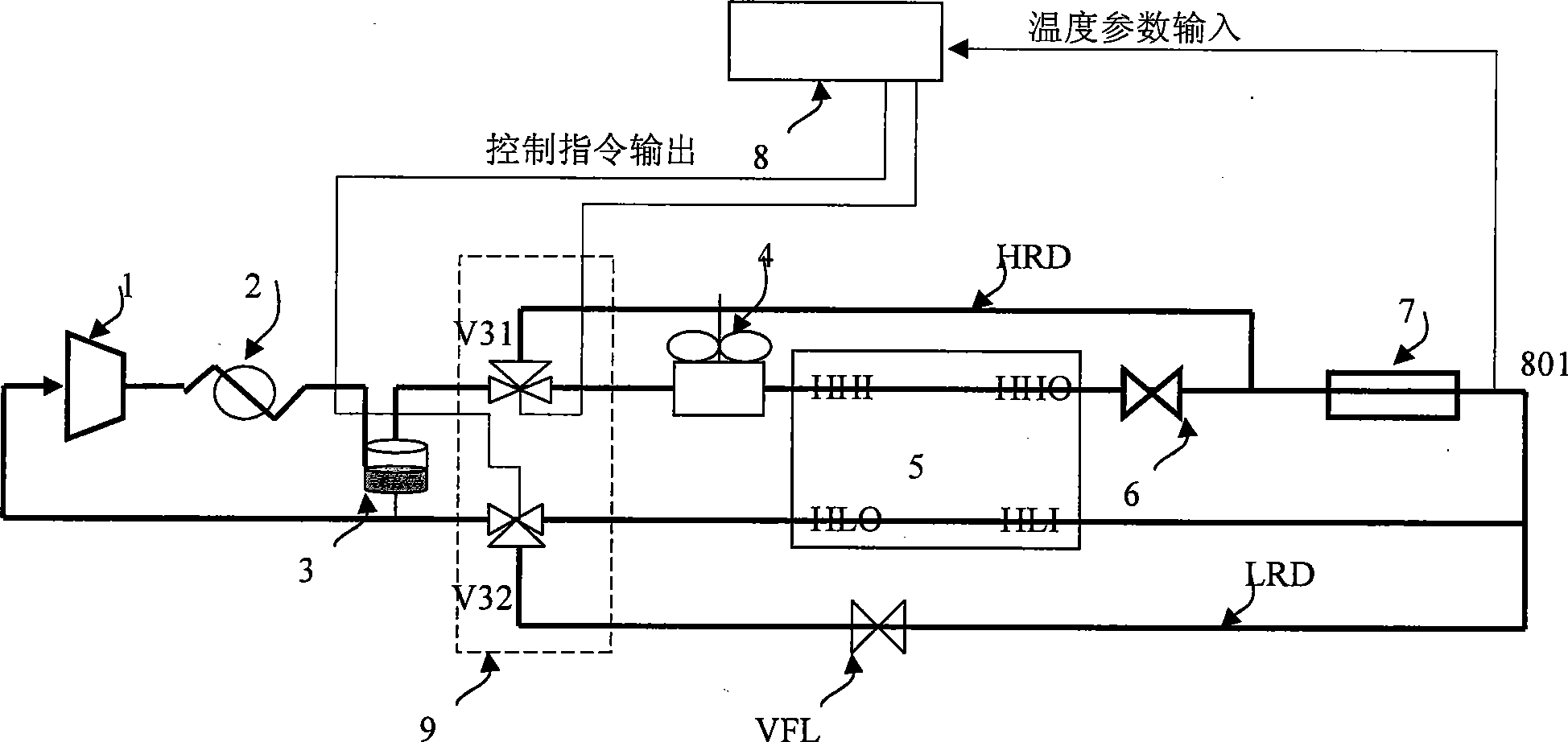

[0052] Embodiment 2: adopt figure 2 The refrigeration process and control system shown include compressor 1, heat accumulator 2, lubricating oil separator 3, aftercooler 4, recuperation heat exchanger unit 5, throttling refrigeration element 6, evaporator unit 7, and control unit 8 and the control execution unit group 9; the control execution unit group 9 includes a high-pressure three-way reversing valve V31, a high-pressure heating pipeline HRD, a low-pressure three-way reversing valve V32, a low-pressure heating pipeline LRD and a flow control element VFL; system connection way see figure 2 As shown, the refrigeration circuit C1 is composed of a compressor 1, a heat accumulator 2, a lubricating oil separator 3, an aftercooler 4, a recuperation heat exchanger unit 5, a throttling refrigeration element 6 and an evaporator unit 7; Compressor 1, heat accumulator 2, lubricating oil separator 3, high-pressure heating pipeline HRD, evaporator unit 7, and low-pressure heating pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com