Flat-plate laser cladding composite alloy layer heater

A laser cladding and composite alloy technology, which is applied in laser welding equipment, metal processing equipment, metal material coating technology, etc., can solve problems such as difficult melting and casting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

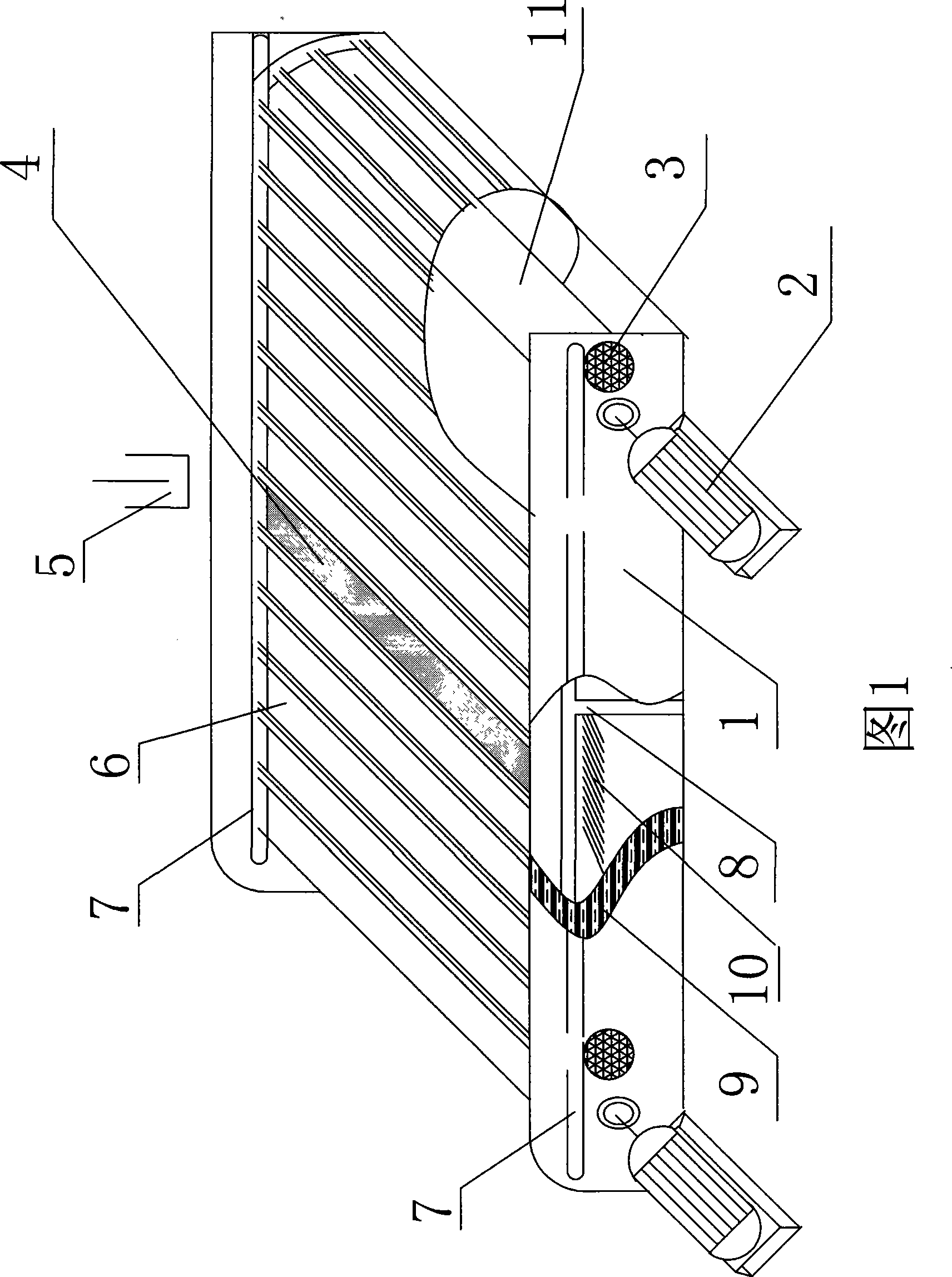

[0015] Flat plate laser cladding composite alloy surface heater, including furnace body 1, roller shutter track 7, thermal insulation shutter cover plate 6; the wall around the furnace body 1 is provided with insulation bricks 9, and the upper ends of both sides of the furnace body 1 are provided with roller shutters The track 7, the thermal insulation roller shutter cover 6 is located in the roller shutter track 7, the laser operation area 4 is arranged above the thermal insulation shutter cover 6, the laser head 5 is located above the laser operation area 4, and the two sides of the thermal insulation shutter cover 6 The ends correspond to the winding axles 11 fixed at both ends, and the winding axles 11 at both ends are respectively connected to the output shafts of the two synchronous motors 2, and the control ends of the two synchronous motors 2 are connected to the controller through wires.

[0016] A stand 8 is arranged under the thermal insulation roller shutter cover p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com