Full floating turbine driven compressing ejector

A catapult and compression spring technology, which is applied in the direction of launch/drag transmission, etc., can solve the problems of frequent replacement of U-shaped sealing strips, high maintenance costs, and high material requirements, and achieve shortened take-off intervals, high thermal energy utilization, and structure. compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

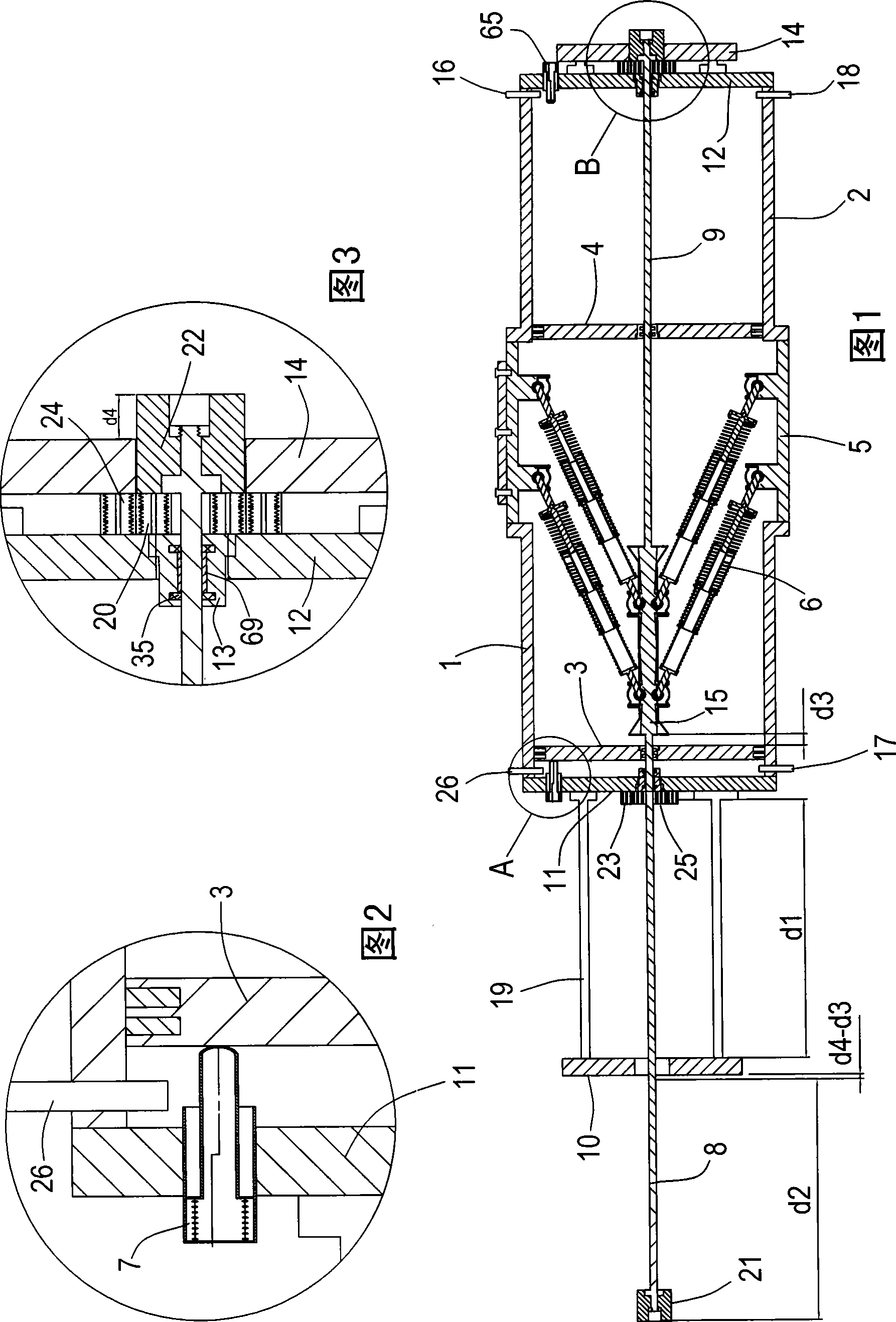

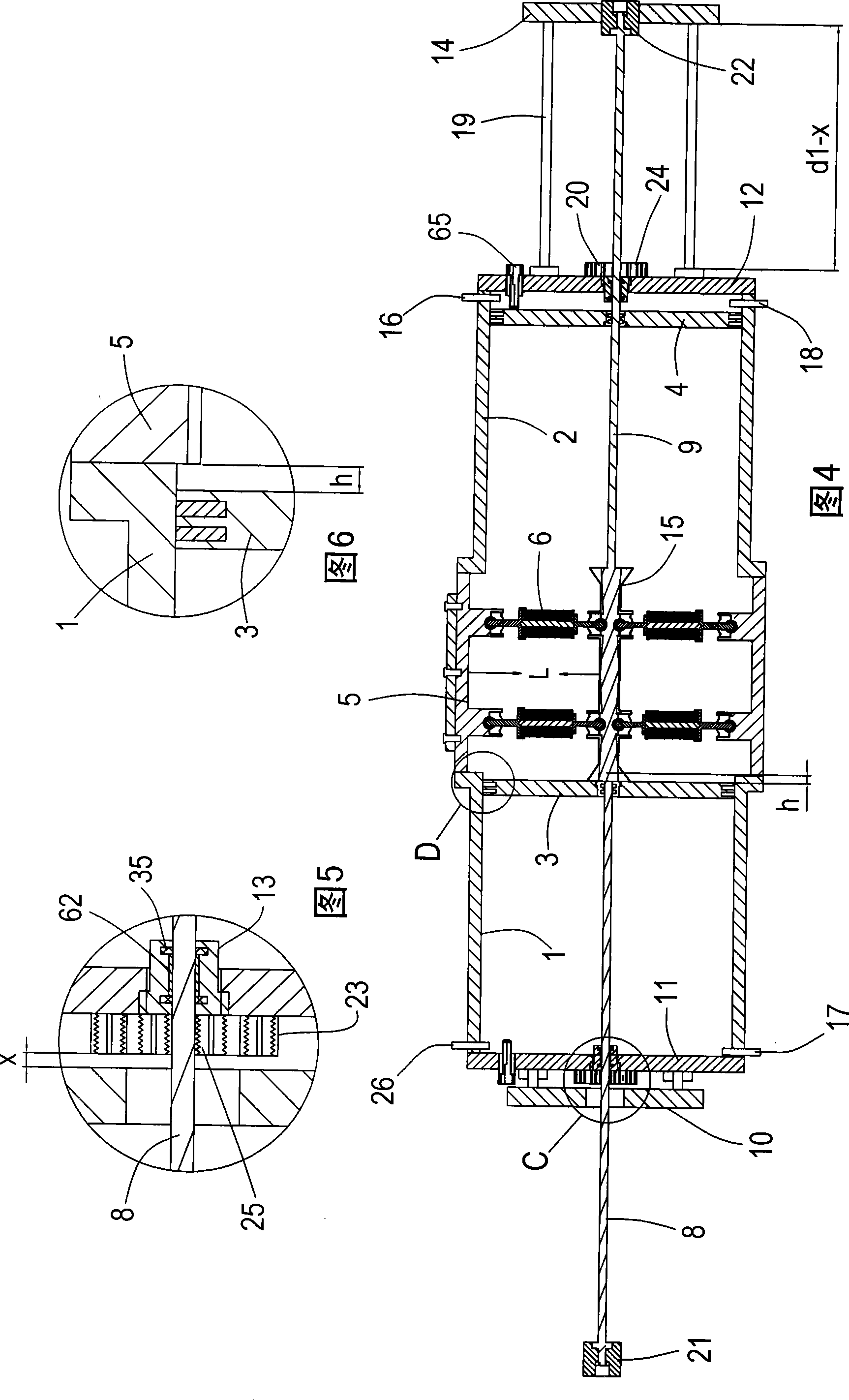

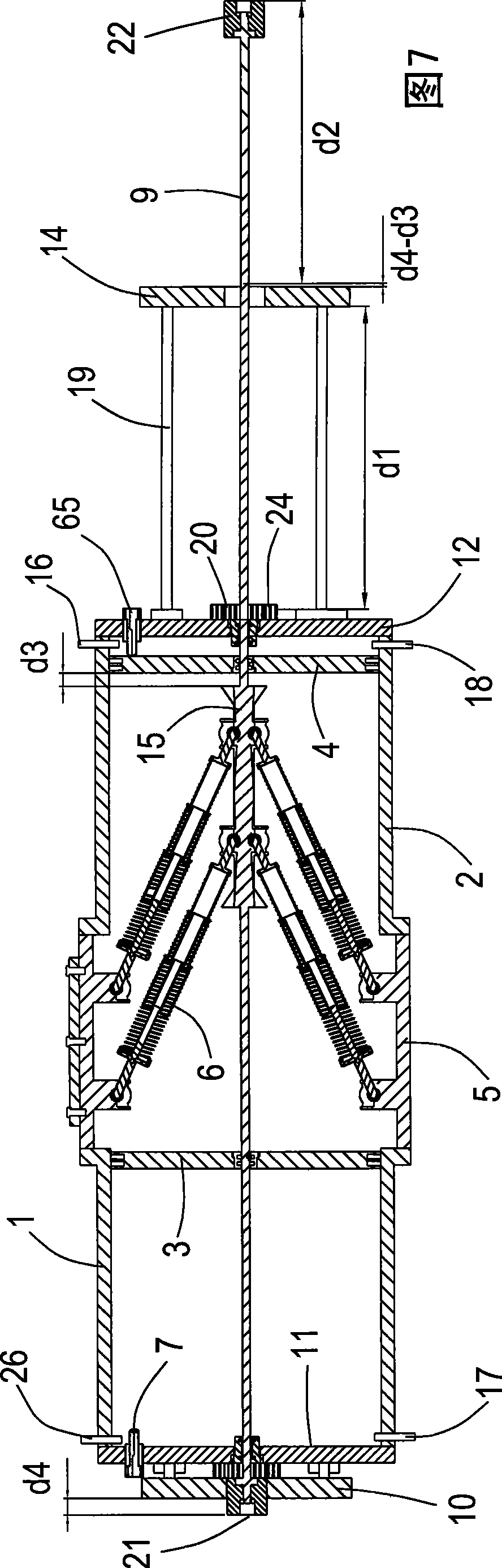

Image

Examples

Embodiment 2

[0089] Embodiment 2, please refer to Fig. 22 and Fig. 23. In this embodiment, there are two groups of elastic swing rods, and the number of each group is 5, and its working principle is the same as that of Embodiment 1.

Embodiment 3

[0090] Embodiment 3, please refer to Fig. 24 and Fig. 25, the full-float pneumatic compression catapults of the present invention can be used in parallel, for example, three full-float pneumatic compression catapults 70, 71, 72 can be arranged side by side together, The tops of the three full-floating pneumatic compression catapults 70, 71, 72 are provided with a parallel frame 64, which is a board with three arcs, and the parallel frame 64 is fixed with the three full-floating pneumatic compression ejectors by bolt fasteners. The back base 5 of the device 70, 71, 72 is affixed.

[0091] Parallel bar 66 is a rectangular solid steel part, and left and right ejection seats 21,22 are cylinders, and left and right ejection seats 21,22 are respectively screwed on the shoulders of left and right shooting rods 8,9.

[0092] The parallel bar 66 fixes and connects the left ejection seats 21 of the full-floating pneumatic compression ejectors 70, 71, 72 through bolts 32, and the paralle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com