Core of cylindrical battery and method for assembling the core into the battery case

A technology for cylindrical batteries and battery casings, which is applied in the field of battery cells loaded into battery casings and cylindrical batteries. It can solve the problems affecting battery durability and unfavorable reliable connection, etc., and achieve reliable connection and reasonable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment one (cell of cylindrical battery)

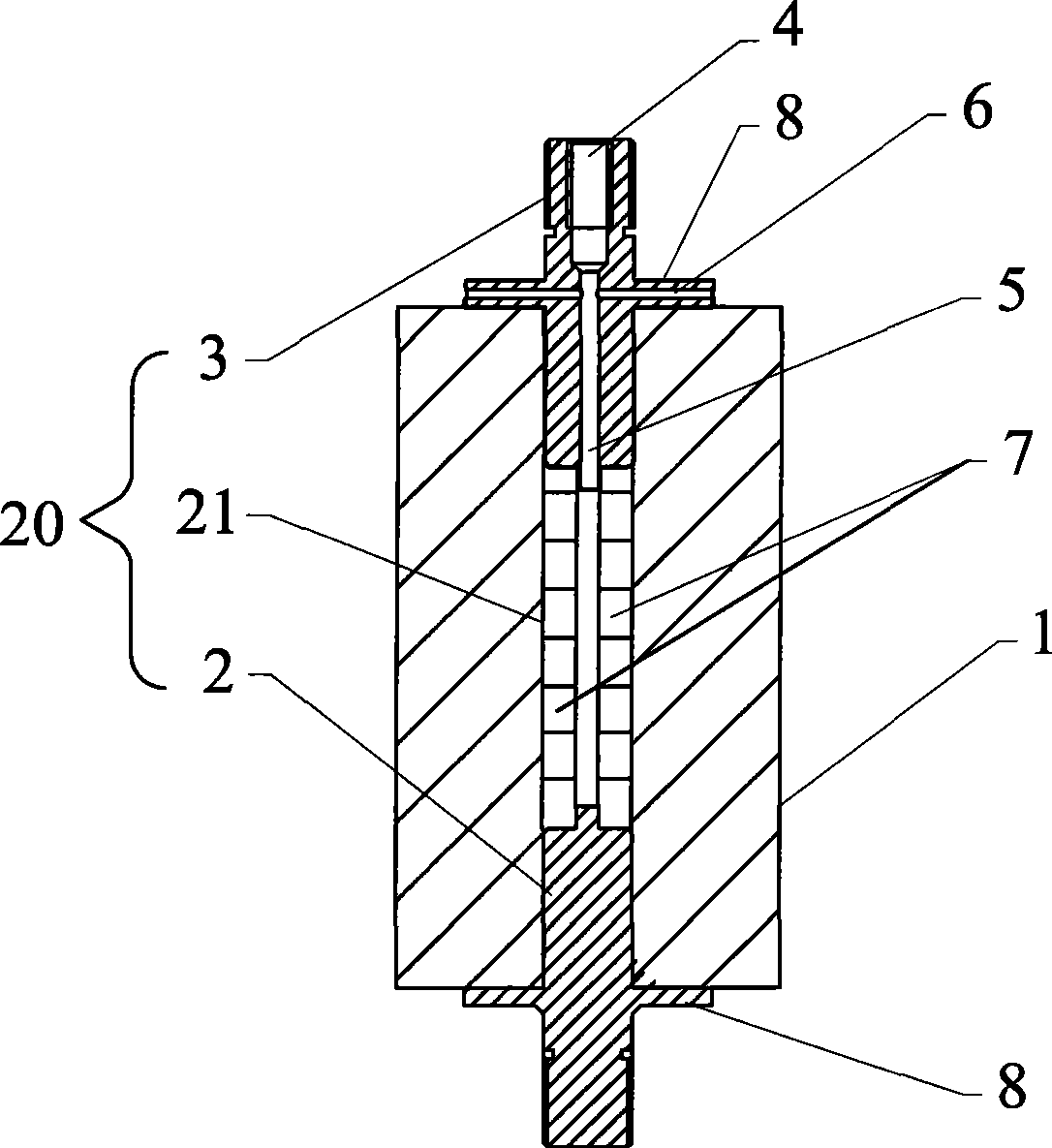

[0036] figure 1 , figure 2 and image 3 One embodiment of the cell of the cylindrical battery of the present invention is shown. figure 2 shows the use of figure 1 The structure of the battery with the cells shown.

[0037] The cylindrical cell includes a reel 20 and a reel 1 wound by positive and negative pole pieces and a separator. The reel 1 is wound on the reel 20, and the reel 20 runs through the reel 1; the lower section of the reel 20 is the positive end 2 1. The upper section is the negative terminal 3, the positive terminal 2 is electrically connected to the positive electrode sheet of the winding core 1, the negative terminal 3 is electrically connected to the negative electrode sheet of the winding core 1, and the middle section of the reel 20 is an insulating member 21, which is connected to the positive electrode sheet. The pole 2 and the negative pole 3 are fixedly connected together; the end of the po...

Embodiment 2

[0038] Embodiment 2 (the method for packing the electric core in embodiment 1 into a cylindrical casing)

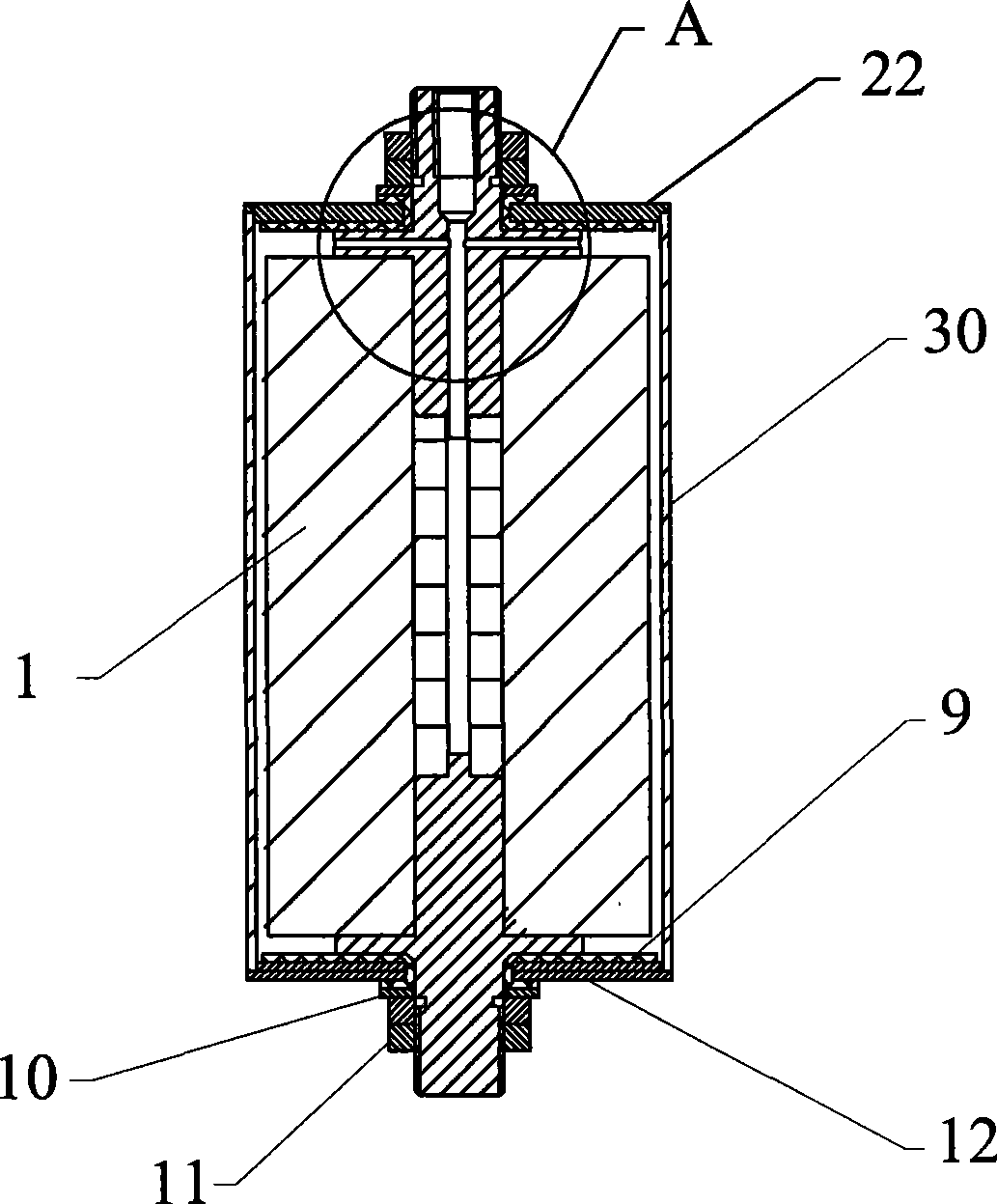

[0039] The process of packing the cylindrical cell in embodiment 1 into the cylindrical shell of the battery can be found in figure 2 -- Figure 7 .

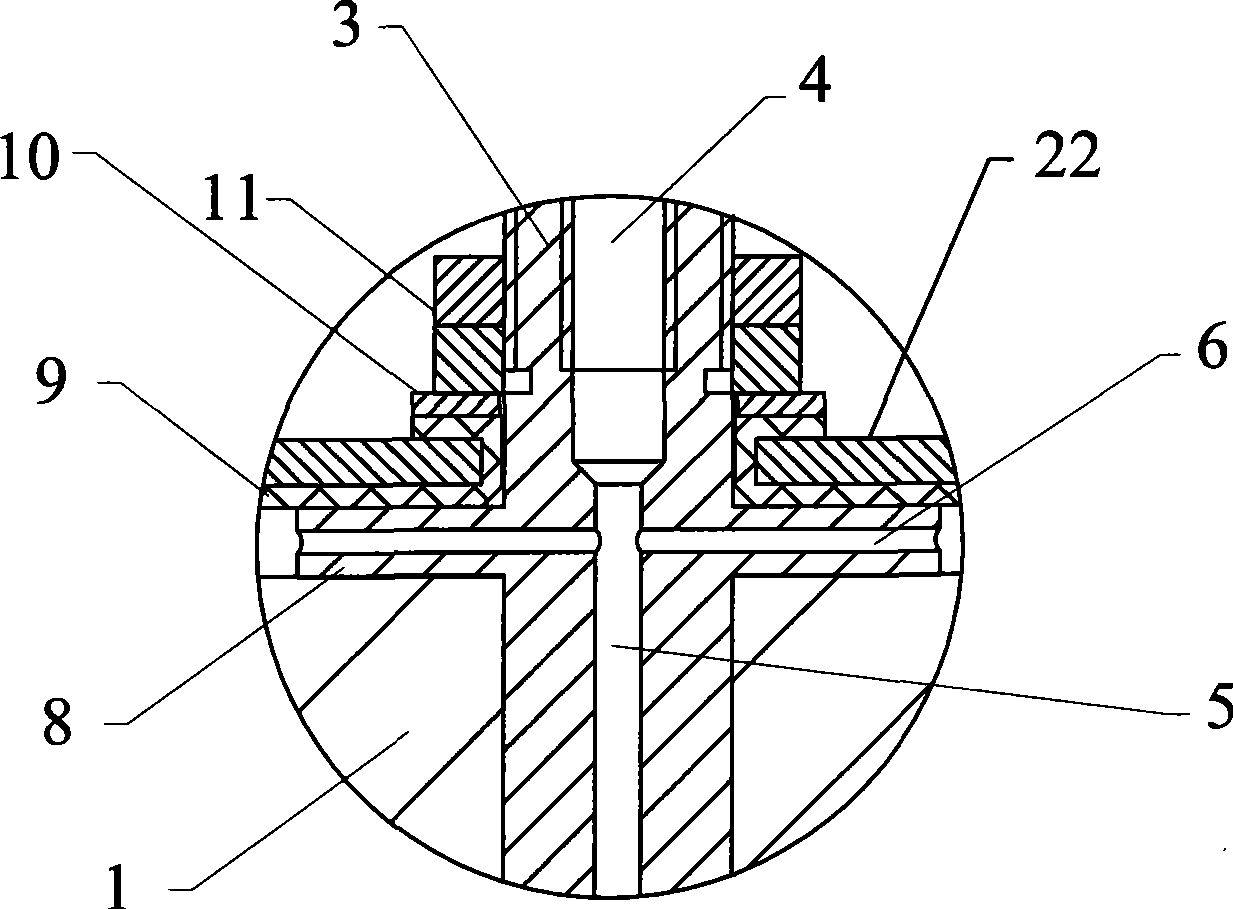

[0040] Such as Figure 4As shown, before the cell is loaded into the cylindrical case of the battery, a second end cap 12 with a middle hole is installed on the positive end 2, and the second end cap 12 is located between the positive end 2 and the second end cap 12. The insulating sealing ring 9 is put on the positive end 2, and then the gasket 10 and the nut 11 are installed on the positive end 2 in sequence, and the nut 11 is tightened so that the second end cap 12 is pressed by the pressure plate 8 and the nut on the positive end 2. Cap 11 is clamped.

[0041] Such as Figure 5 As shown, the upper port of the battery cylindrical casing 30 is welded with a first end cap 22 with a middle hole, and the insulating sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com