Method for eliminating measurement error of transformer by active impedance vector electric voltage synthesis

A technology of active impedance and measurement error, applied in the direction of inductors, measuring electrical variables, transformers, etc., can solve the problems of poor performance of glass film alloy iron core, complex circuit, difficult selection of circuit parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

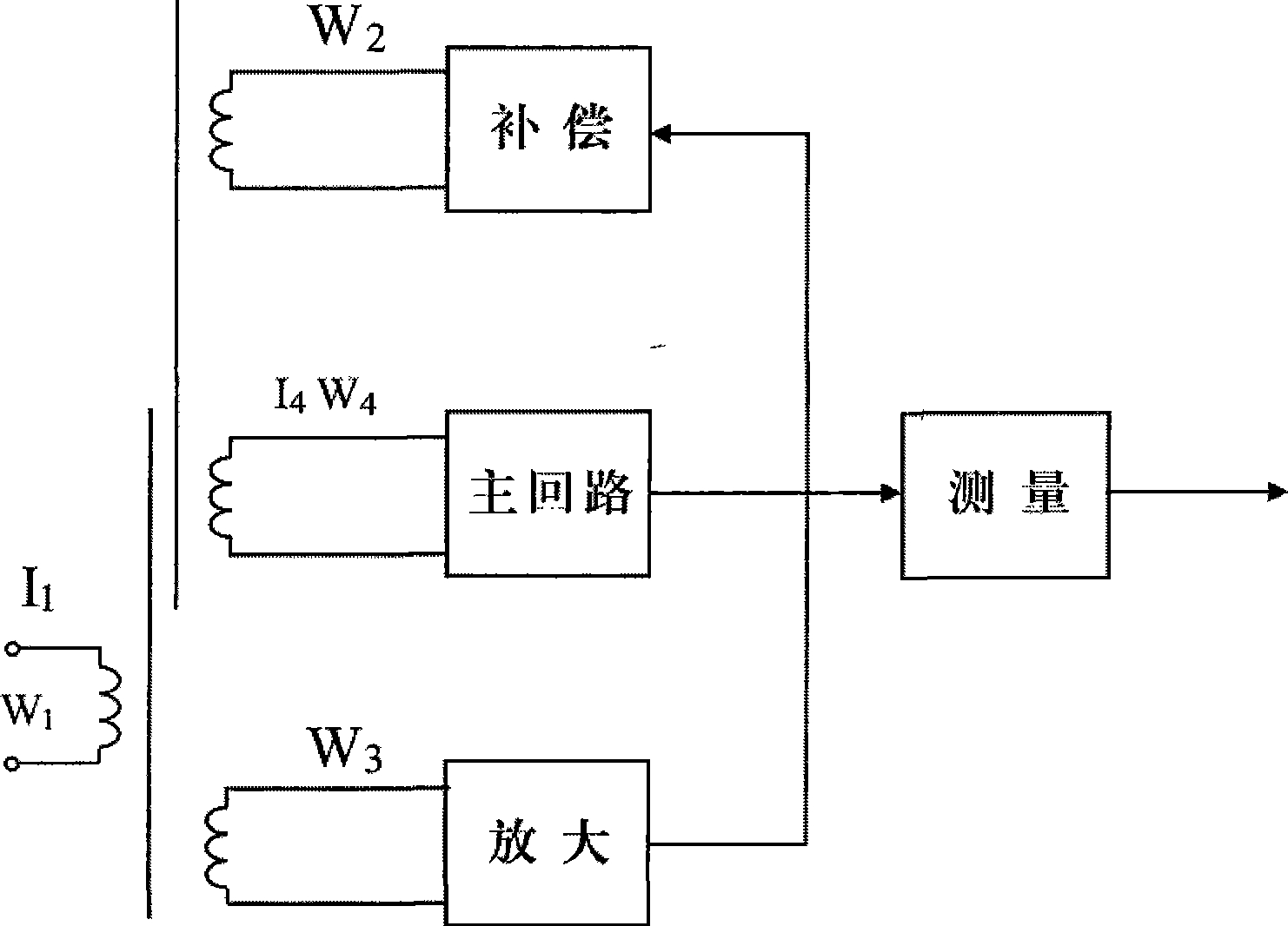

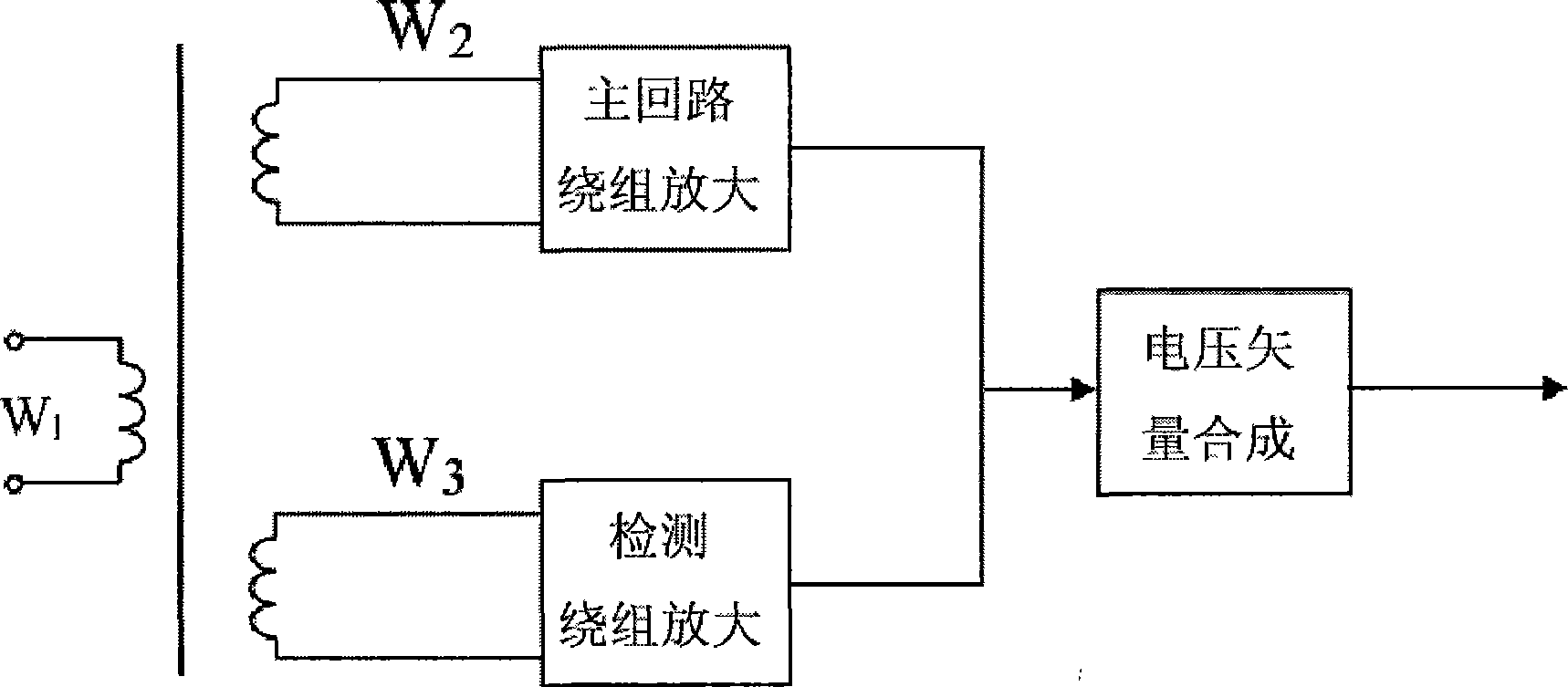

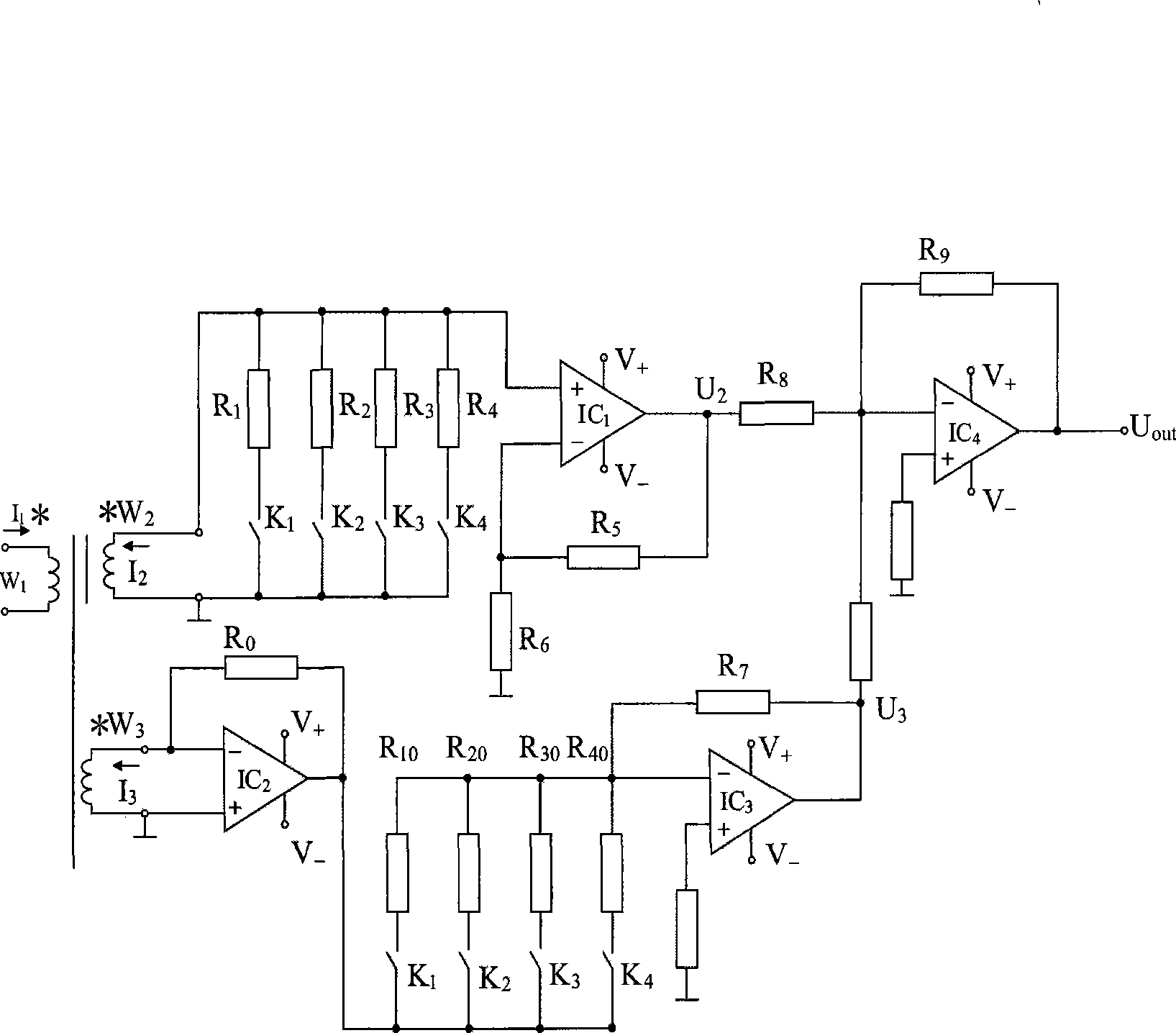

[0031] Such as figure 2 , image 3 As shown, a method to eliminate the measurement error of the transformer through the vector voltage synthesis of the active impedance, the main circuit current of the secondary winding of the transformer and the current of the detection winding are independently detected and converted into voltages, and then the amplified two The circuit voltage is input to the adding operational amplifier for summing, and the vector voltage synthesis output of the active impedance is completed.

[0032] The main circuit current is converted into a voltage signal through the conversion resistors connected in parallel at both ends of the secondary winding W2, input to the non-inverting terminal of the first general-purpose operational amplifier IC1 to amplify the output, and then connected to the inverting terminal of the adding operational amplifier IC4 for input; the detection winding W3 The two ends are connected in parallel to the in-phase and inverting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com