Phase change energy storage low temperature face mask substrate material and preparation method thereof

A phase-change energy storage and energy storage technology, which is applied in the fields of fiber chemical characteristics, medical science, absorbent pads, etc., can solve the problems of mask substrates that have not been disclosed in relevant literature, and achieve improvement and shrinkage of skin pores, good market prospects, and promotion The effect of shrinking pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: prepare the low-temperature mask base material of microcapsule coating structure

[0040] 1) Use paraffin wax with a phase transition temperature of 15°C or 30# paraffin wax microcapsules with a phase transition temperature of 30°C

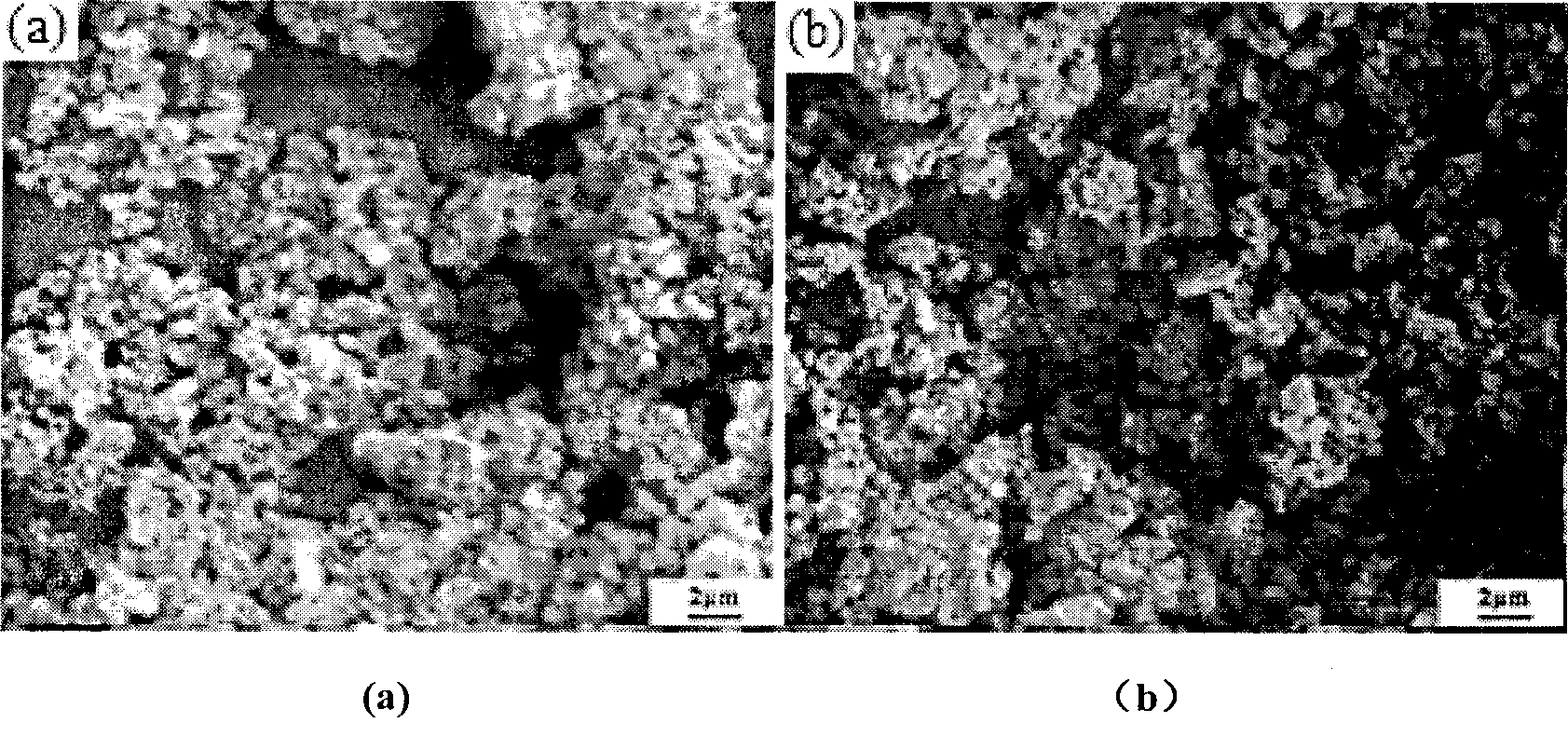

[0041] Take 4.5g of 30# phase-change paraffin wax with a phase transition temperature of 30°C, add 0.5g of Span80 and Tween 80 in a mass ratio of 0.45:0.55, and dissolve 40g of an aqueous solution containing 0.5wt% polyvinyl alcohol under heating and stirring Add it into the above oil phase, then add 1.1 g of 0.13 wt% KCl solution, continue heating and stirring for 30 min, and fully emulsify the mixed solution. Add 0.5g of 10% acetic acid and 7.2g of ethyl orthosilicate to the above emulsion, place it in a water bath at 60°C, react for 3 hours under stirring, age at room temperature for 5 hours, filter and wash to obtain the phase change energy storage micro capsule. The SEM photograph of the microcapsules is as figure 1 As...

Embodiment 2

[0045] Embodiment 2: prepare another kind of low-temperature mask substrate of microcapsule coating structure

[0046] A mixture of paraffin wax and dodecanoic acid with a phase change temperature of 20°C is selected as the phase change material to make microcapsules, and the prepared microcapsules are added to an aqueous solution containing 0.5 to 8 wt% CMC, stirred evenly to form a slurry, and then used Spraying or brushing is applied to the surface of mask substrates such as non-woven fabrics or dust-free paper to form a coating to make a low-temperature mask substrate. The coating amount of the microcapsules can be 35% of the total weight of the base material of the low-temperature facial mask, and the average particle diameter of the microcapsules is 5-7 μm.

[0047] The difference between the low-temperature mask base material made in Example 2 and the low-temperature mask base material made in Example 1 is that the microcapsules coated on the surface of the non-woven fa...

Embodiment 3

[0048] Embodiment 3: prepare the low-temperature mask base material of microcapsule composite fiber structure

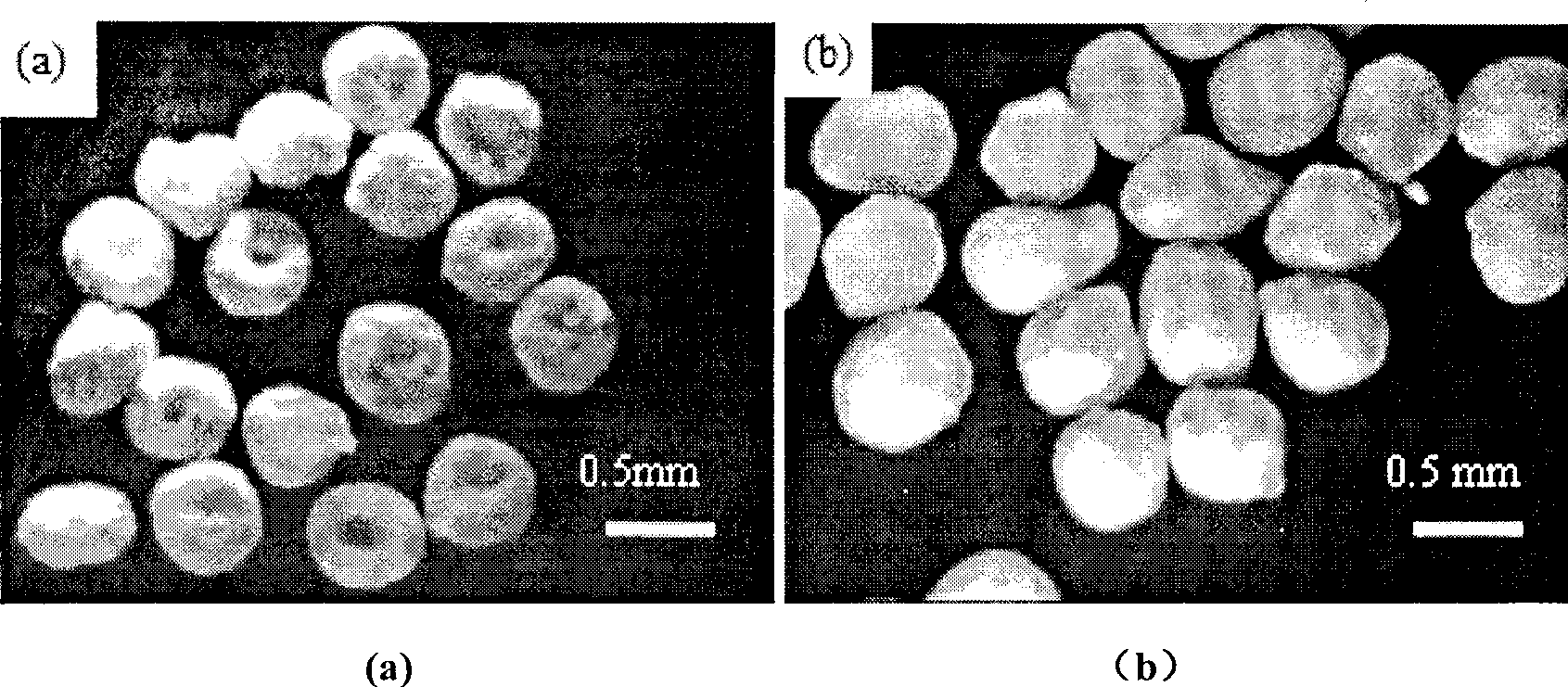

[0049] 1), using 25# paraffin microcapsules with a phase transition temperature of 25°C

[0050] Take 4.5g of 25# paraffin wax with a phase transition temperature of 25°C, add 1.5g of emulsifier compounded by Span 80 and Tween 80 in a mass ratio of 0.4:0.6, add 60g of a 1.5wt% aqueous solution containing polyvinyl alcohol under heating and stirring conditions , and then add 1.1 g of 0.13 wt % NaCl solution, and emulsify for 30 min under heating and stirring. After the emulsification is relatively complete, add 0.25g of 1wt% hydrochloric acid solution and 21.6g of ethyl orthosilicate, place in a water bath at 60°C for 3 hours under stirring, age for 5 hours, filter and wash to obtain phase change energy storage microcapsules. The enthalpy value of the microcapsules during the phase change process is 58.6J / g, and the content of 25# phase change wax (the enthalpy value...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com