Method for preparing polyurethane skincare microcapsule

A technology of microcapsules and polyurethane, which is applied in the direction of microcapsule preparation, preparation of microspheres, textiles and papermaking, etc. It can solve the problems of non-conformity with ecological and environmental protection, and achieve the effect that the reaction conditions are easy to meet, the operation is simple, and the raw materials are simple and easy to obtain.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

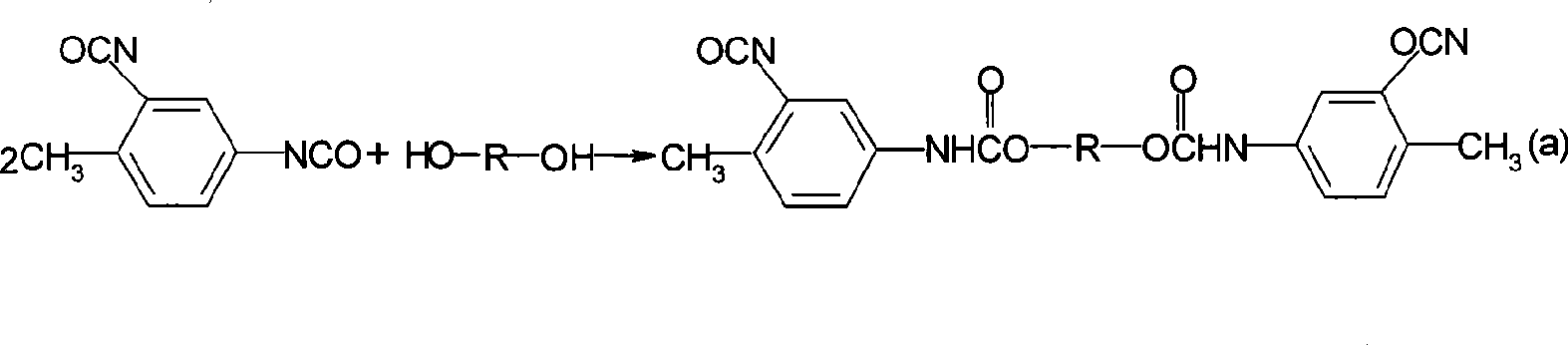

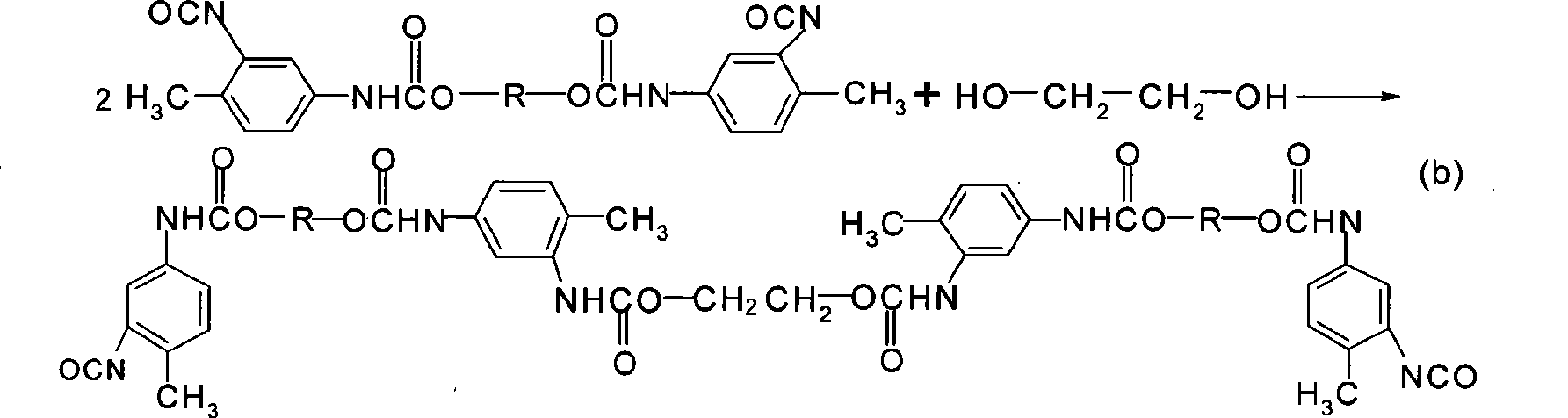

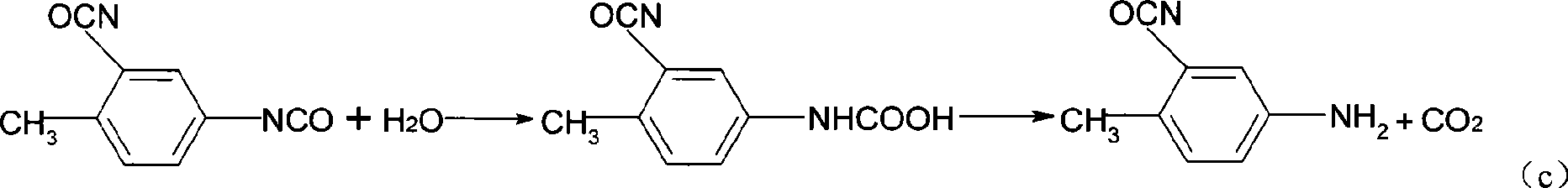

Method used

Image

Examples

Embodiment 1~4

[0029] Mix 6.0g of olive oil and 5.0g of TDI evenly, and slowly add them into 150ml of water containing 1.7g of polyvinyl alcohol at a series of temperatures (as shown in the table below), and stir (3000rpm) while adding, until emulsified to a uniform dispersion In the system, slowly add 9.0g PEG and 0.02g catalyst triethylenediamine, stir at 10°C for 30min, then raise the temperature to 70°C, add 1ml chain extender ethylene glycol and react for 1 hour to obtain the product. The test results are shown in Table 1.

[0030] It can be seen from the table below that the initial temperature of the reaction should be controlled to reduce the occurrence of side reactions or excessive reactions, so as to obtain more polyurethane skin care microcapsules.

[0031] Table I

[0032]

[0033] 2. The influence of PEG molecular weight

Embodiment 5~7

[0035] After mixing 10.0g olive oil and 5.5g TDI evenly, slowly add it into 150ml water containing 5.2g polyvinyl alcohol at 10°C, stir while adding (3000rpm), when emulsified to a uniform dispersion system, slowly add 9.0g of PEG with a series of molecular weights (as shown in the table below) and 0.02g of catalyst triethylenediamine were stirred at 10°C for 30 minutes, then the temperature was raised to 70°C, and 1ml of chain extender ethylene glycol was added to react for 1 hour to obtain the product. The obtained product is suction-filtered, washed, and dried below 80°C to obtain micron-sized microcapsules.

[0036] Dissolve the sample with anhydrous alcohol, oscillate under ultrasonic waves, after the particles are evenly distributed, take a sample and drop it on the sample stage, and observe it under a scanning electron microscope after the alcohol evaporates to dryness. It was found that the surface of the prepared microcapsules became denser and smoother with the incre...

Embodiment 8~10

[0041] After mixing 8.0g of olive oil and 5.2g of TDI evenly, slowly add it into 150ml of water containing 2.6g of polyvinyl alcohol at 10°C, and stir at a series of rotational speeds (as shown in the table below), when it is emulsified to a uniform dispersion system , slowly add 9.0g PEG and 0.02g catalyst triethylenediamine, stir at 10°C for 30min, then raise the temperature to 70°C, add 5ml chain extender ethylene glycol to react for 1 hour, and the product is obtained. The test results are shown in Table 3.

[0042] It can be seen from the table below that due to the non-uniform magnetic stirring speed and low rotational speed, a small amount of microcapsules can be produced because the speed of magnetic stirring is not enough to meet the emulsification requirements; as the speed increases, the microcapsule particles decrease and the size distribution is uniform.

[0043] Table three

[0044]

[0045] 4. Preparation of microcapsules ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com