Cold-proof, impactive and high toughness casting nylon and method for producing the same

A casting nylon, impact-resistant technology, applied in the field of material science, can solve the problems of insignificant cold resistance, high production cost, complicated process, etc., and achieve the effects of excellent comprehensive mechanical properties, low production cost, and uniform distribution of fillers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

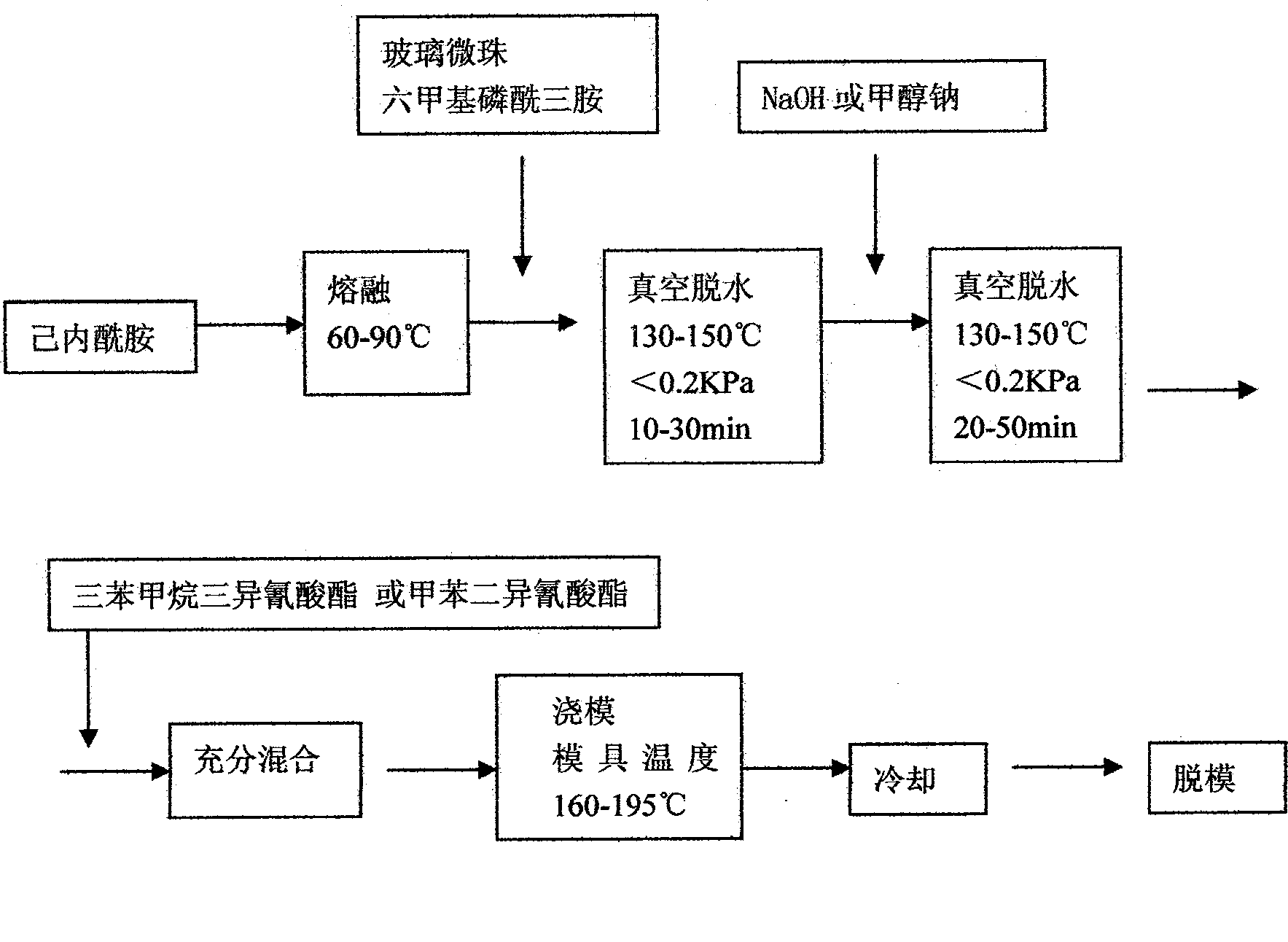

Image

Examples

Embodiment 1

[0050] Each raw material component and percentage by weight are in the technical scheme of the present invention:

[0052] Catalyst using sodium hydroxide 0.1%

[0053] Activator Triphenylmethane triisocyanate 0.1%

[0054] Toughening agent using hexamethylphosphoric triamide (HPT) C 6 h 18 N 3 OP 1.9%

[0055] Glass beads 400 mesh 1.9%

[0056] The technological process of the embodiment of the present invention:

[0057] Each raw material component operates according to the following steps:

[0058] 1. Melt caprolactam at 60°C;

[0059] 2. Add glass microspheres and hexamethylphosphoric triamide (HPT), dehydrate under vacuum <0.2KPa for 20 minutes, and the temperature is 130°C;

[0060] 3. After the dehydration is completed, add sodium hydroxide and vacuum dehydrate again for 30 minutes at a temperature of 140°C;

[0061] 4. After dehydration, add the activator triphenylmethane triisocyanate, mix well, quickly pour into the mold that ...

Embodiment 2

[0063] Each raw material component and percentage by weight are in the technical scheme of the present invention:

[0064] Polyamide monomer 65.4%

[0065] Catalyst using sodium methoxide 0.65%

[0066] Activator using toluene diisocyanate 1.3%

[0067] Toughening agent using hexamethylphosphoric triamide (HPT) C 6 h 18 N 3 OP 13%

[0068] Glass beads 200 mesh 19.6%

[0069] The technological process of the embodiment of the present invention:

[0070] Each raw material component operates according to the following steps:

[0071] 1. Melt caprolactam at 60°C;

[0072] 2. Add glass microspheres and hexamethylphosphoric triamide (HPT), dehydrate under vacuum <0.2KPa for 20 minutes, and the temperature is 130°C;

[0073] 3. After the dehydration is completed, add sodium methoxide, and vacuum demethanol again for 30 minutes at a temperature of 140°C;

[0074] 4. After dehydration, add the activator triphenylmethane triisocyanate, mix well, quickly pour it into a mold tha...

Embodiment 3

[0076] Each raw material component and percentage by weight are in the technical scheme of the present invention:

[0077] Polyamide monomer 86.2%

[0078] Catalyst using NaOH 0.1%

[0079] Activator Triphenylmethane triisocyanate 0.17%

[0080] Toughening agent using hexamethylphosphoric triamide (HPT) C 6 h 18 N 3 OP 6.8%

[0081] Glass beads 250 mesh 6.8%

[0082] The technological process of the embodiment of the present invention:

[0083] Each raw material component operates according to the following steps:

[0084] 1. Melt caprolactam at 60°C;

[0085] 2. Add glass microspheres and hexamethylphosphoric triamide (HPT), dehydrate under vacuum <0.2KPa for 20 minutes, and the temperature is 130°C;

[0086] 3. After the dehydration is completed, add sodium hydroxide and vacuum dehydrate again for 30 minutes at a temperature of 140°C;

[0087] 4. After dehydration, add the activator triphenylmethane triisocyanate, mix well, quickly pour it into a mold that has been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com