Composite bus bar manufacturing method

A technology of composite busbar and manufacturing method, which is applied in the directions of busbar installation, cable installation, busbar/circuit layout, etc., can solve the problems of suboptimal electrical performance, low production efficiency, heavy weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

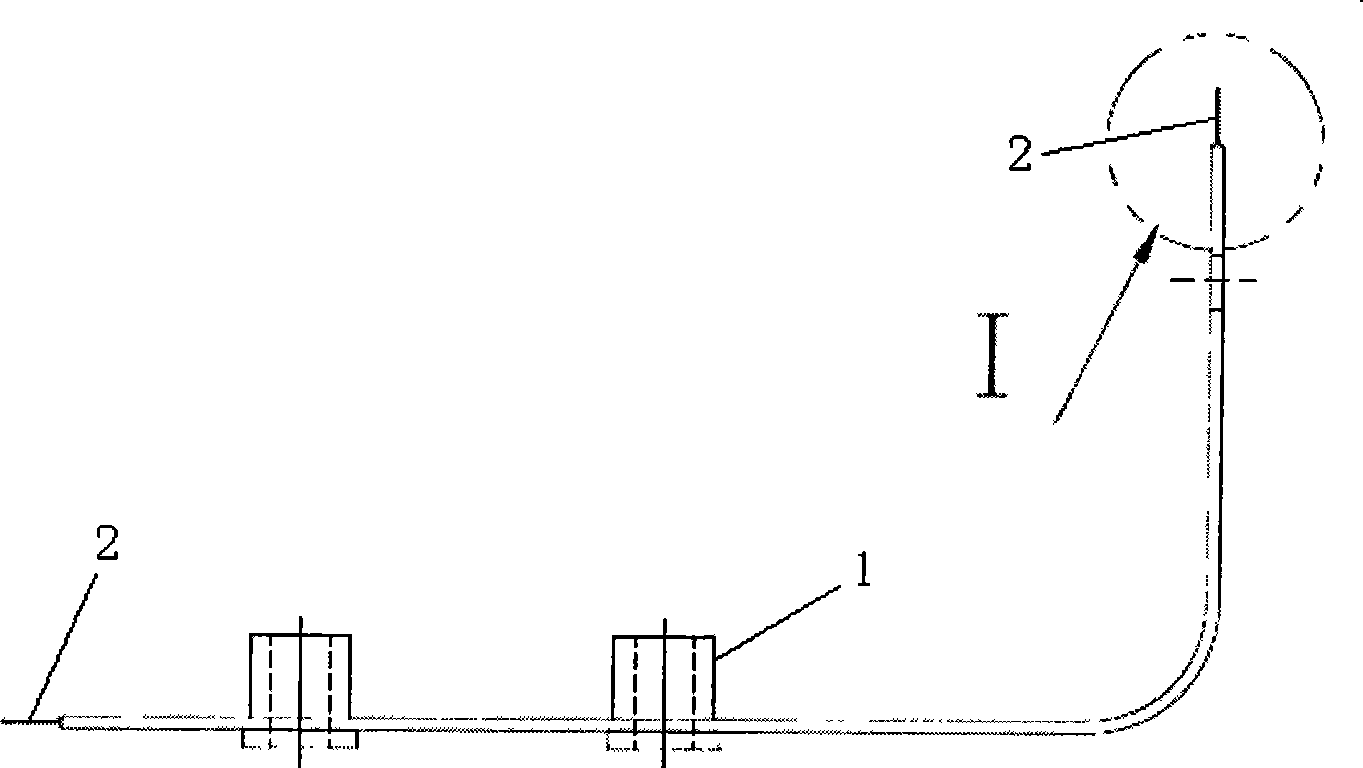

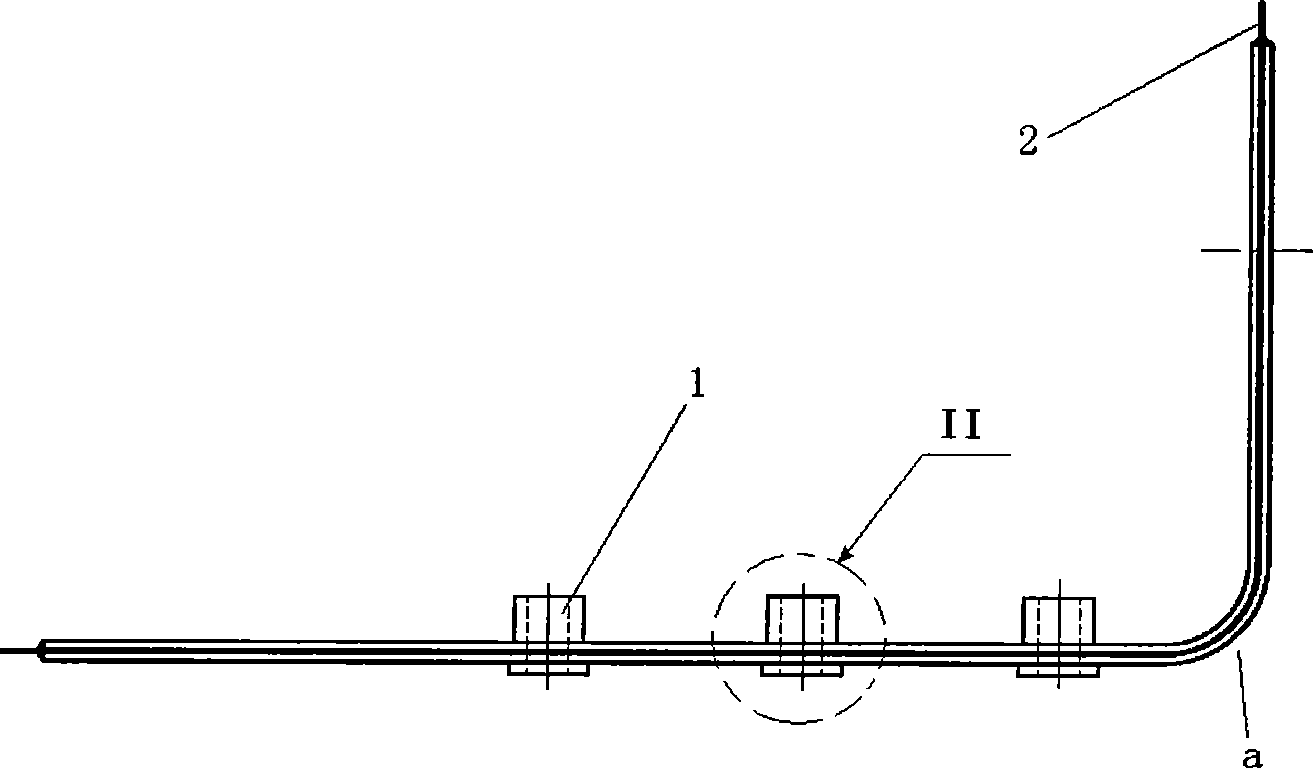

[0029] A method for making a composite busbar includes the following steps:

[0030] 1) According to the conventional processing of the conductor plate, the connecting boss on the conductor plate is stamped and formed by the body material, and the conductor post is welded on the conductor plate and the required coating is plated as required;

[0031] 2) Take the processed conductor plate in step 1), cut the flexible glue-coated insulating film according to the shape of the conductor plate, and reserve 3-15 mm of insulating film on the insulating film corresponding to the middle opening and edge of the conductor plate for edge sealing ;

[0032] 3) The insulating film of step 2) is correspondingly superimposed on the upper and lower sides of the conductor plate according to the shape of the conductor plate;

[0033] 4) Place the conductor plate (single-layer or multi-layer) in step 3) in the flat cavity mold and pressurize and heat (select different parameters according to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com