Exposure system and method of manufacturing a semiconductor device

一种曝光系统、光罩的技术,应用在曝光系统领域,能够解决难计测等问题,达到降低生产量、降低制造成本、抑制焦点偏差的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

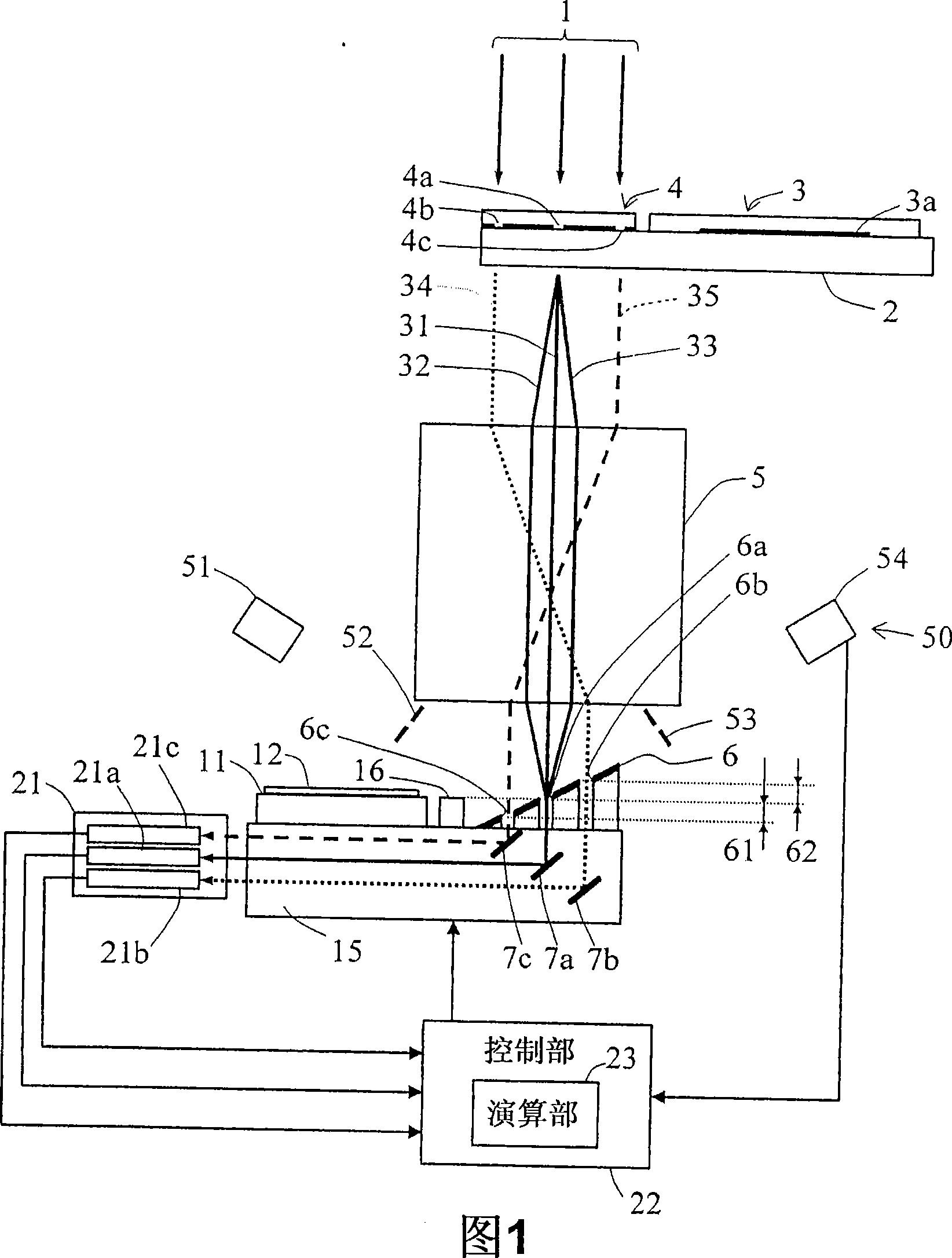

[0049] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings. In the following embodiments, the present invention is embodied as a reduced projection exposure apparatus.

[0050] FIG. 1 is a schematic configuration diagram illustrating the configuration of an exposure apparatus according to an embodiment of the present invention. As shown in FIG. 1, with respect to the exposure apparatus of this embodiment, the exposure light 1 emitted from the exposure light source not shown is irradiated to the mask 3 mounted on the mask stage 2, and passes through the projection lens 5, and makes it appear on the mask 3 The element pattern 3 a formed on the wafer 12 is imaged. The mask stage 2 is arranged between the exposure light source and the projection lens 5 . In addition, on the mask table 2, a spatial image marker body 4 in which a plurality of spatial image markers 4a, 4b, and 4c are arranged is arranged. The mask stage 2 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com