Tft substrate inspecting apparatus

A substrate inspection and substrate technology, which is applied in measurement devices, optics, instruments, etc., can solve the problems of electron beam confusion, electron beam influence, and long-term TFT substrate inspection, so as to reduce the impact and avoid long-term retention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Hereinafter, embodiments of the present invention will be described in detail with reference to the drawings.

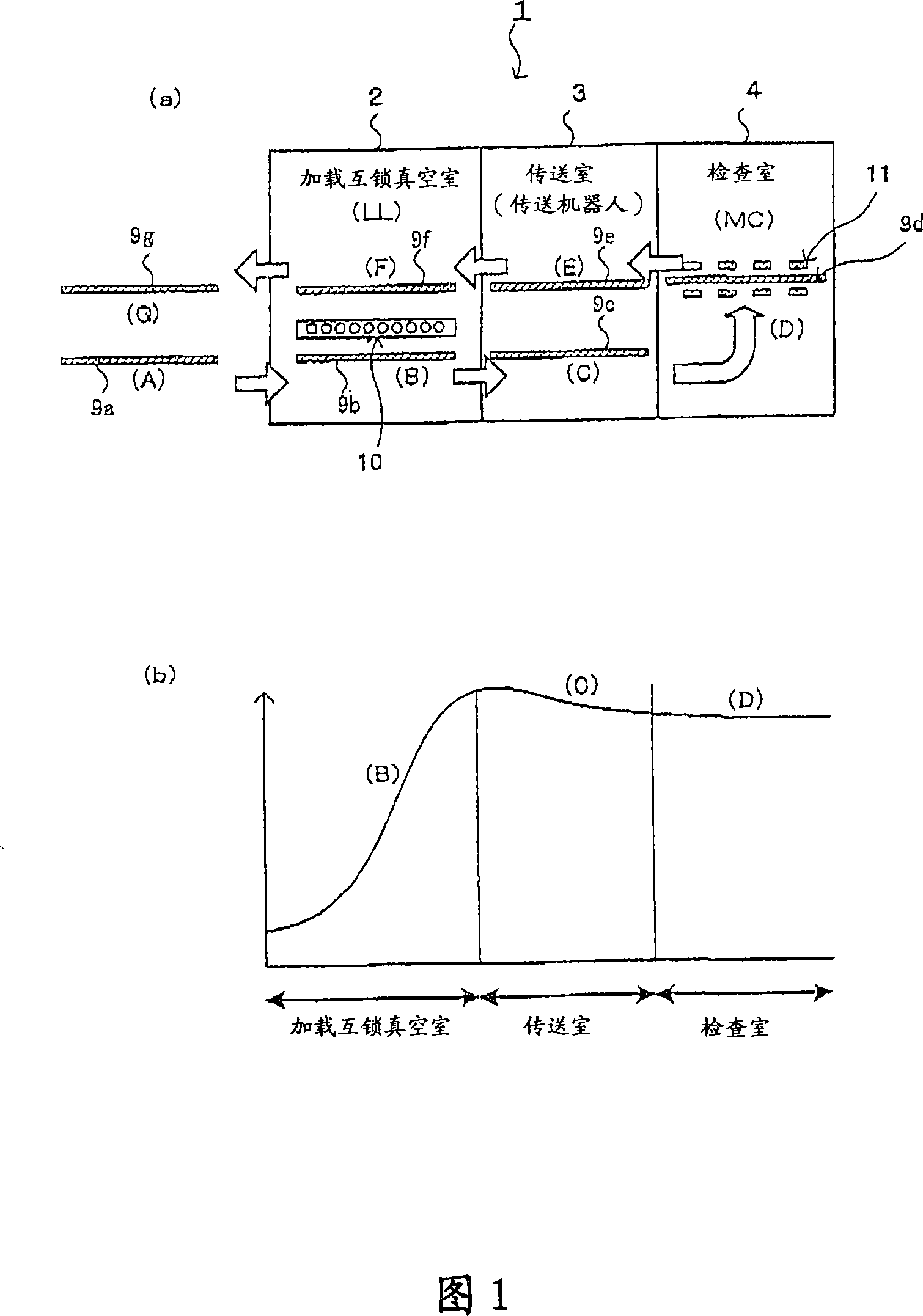

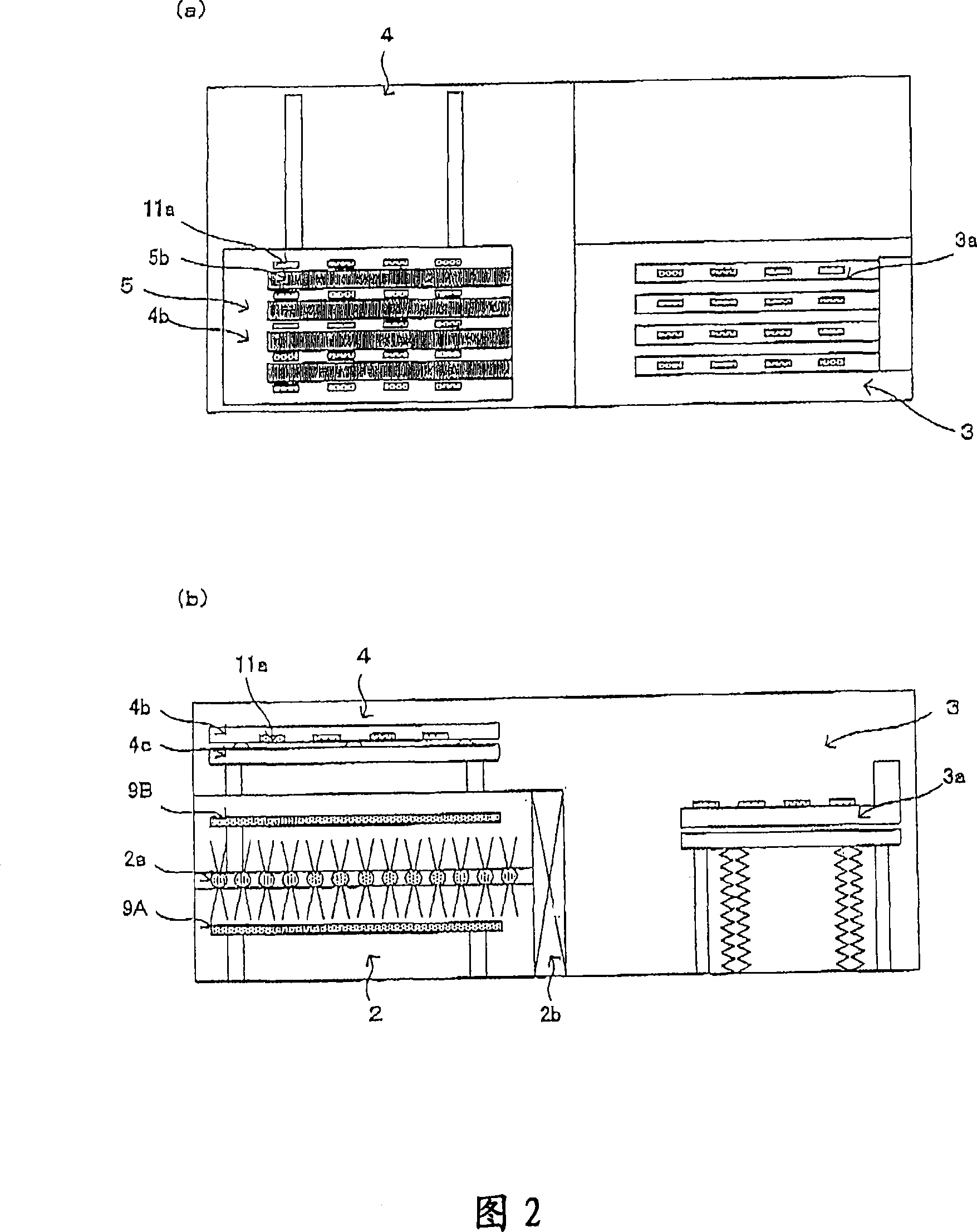

[0039] FIG. 1 is a schematic diagram illustrating a TFT substrate inspection device according to the present invention. The TFT substrate inspection apparatus 1 includes an inspection chamber 4 for inspecting a TFT substrate 9, a load lock chamber (LL chamber) 2 for transferring a TFT substrate 9 between the outside and the TFT substrate inspection apparatus 1, and a load lock chamber in the load lock chamber. 2 and the transfer chamber 3 for transferring the TFT substrate 9 between the inspection chamber 4.

[0040] The load lock chamber 2 includes a heating unit 10 that leads and introduces the TFT substrate 9 between the outside and the transfer chamber 3 , and preliminarily heats the introduced TFT substrate 9 . The heating unit 10 uses a large heat capacity to quickly heat the TFT substrate 9 introduced into the load lock chamber 2 from normal temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com