Preparation method of nano hydroxylapatite biology composite coating

A technology of nano-hydroxyapatite and composite coatings, which is applied in coatings, medical science, prostheses, etc., can solve the problems of poor bonding between coatings and substrates, insufficient bonding force of coatings, constraints, etc., and achieve strong bonding force , to avoid the effects of phase transition and decomposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

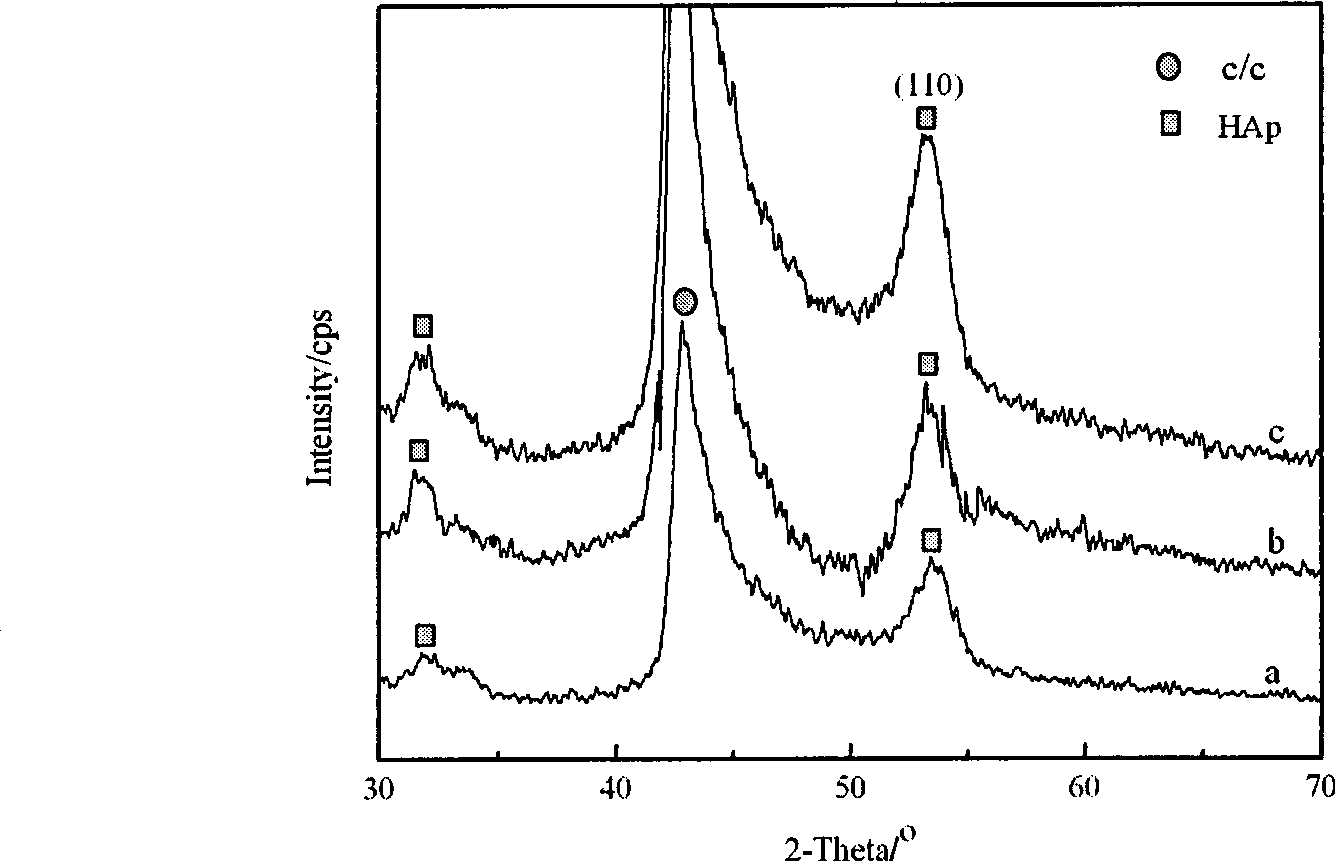

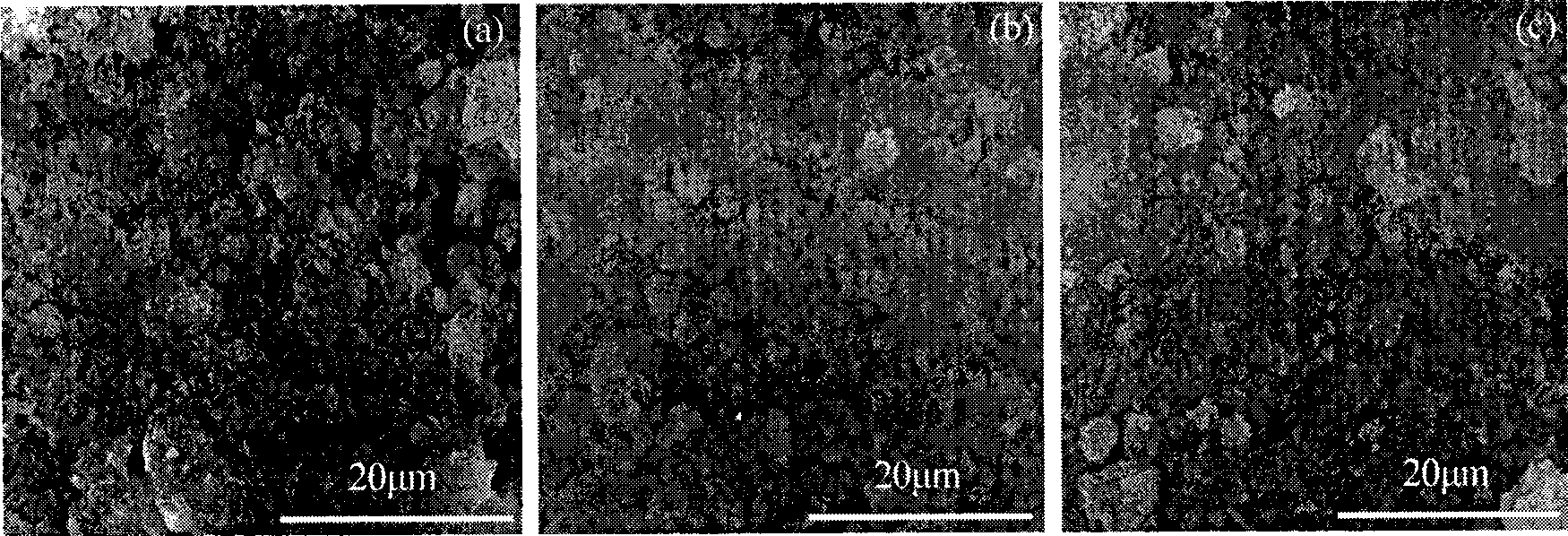

Embodiment 1

[0016] 1) Use commercially available analytically pure Ca(NO 3 ) 2 4H 2 O, (NH 2 ) 2 HPO 4 , CO(NH 2 ) 2 As a raw material, nano-sized hydroxyapatite (Hap) powder was synthesized by sonochemical method. The process is as follows: First, Ca(NO 3 ) 2 4H 2 O and (NH 2 ) 2 HPO 4 Mix according to the molar ratio of Ca:P=1:1.67, add distilled water to dissolve, and make the Ca in the solution 2+ The ion concentration is 0.04mol / L; in the solution according to Ca(NO 3 ) 2 4H 2 O and (NH 2 ) 2 HPO 4 Total mass: urea = 1:5 Add urea powder and stir evenly; under magnetic stirring, put the generation head of the multi-frequency sonochemical generator into the above solution, respectively at 50°C, 80°C and 100°C, with 100W Ultrasonic power, carry out sonochemical synthesis for 45 minutes; filter and wash the suspension, first wash it twice with distilled water, then wash it three times with absolute ethanol, put the filtered material into a vacuum drying oven and dry it...

Embodiment 2

[0022] 1) Use commercially available analytically pure Ca(NO 3 ) 2 4H 2 O, (NH 2 ) 2 HPO 4 , CO(NH 2 ) 2 As a raw material, nano-sized HAp powder was synthesized by sonochemical method. The process is as follows: First, Ca(NO 3 ) 2 4H 2 O and (NH 2 ) 2 HPO 4 Mix according to the molar ratio of Ca:P=1.75, add distilled water to dissolve, and make the Ca in the solution 2+ The ion concentration is 0.05mol / L; in the solution according to Ca(NO 3 ) 2 4H 2 O and (NH 2 ) 2 HPO 4 Total mass: urea=1:7 Add urea powder and stir evenly; under magnetic stirring, put the generating head of the multi-frequency sonochemical generator into the above solution, at 50°C, 80°C and 100°C, use 150W ultrasonic Power, carry out sonochemical synthesis for 60 minutes; filter and wash the suspension, first wash it twice with distilled water, then wash it three times with absolute ethanol, put the filtered material into a vacuum drying oven and dry it at 80°C for 15 hours to obtain Na...

Embodiment 3

[0028] 1) Use commercially available analytically pure Ca(NO 3 ) 2 4H 2 O, (NH 2 ) 2 HPO 4 , CO(NH 2 ) 2 As a raw material, nano-sized HAp powder was synthesized by sonochemical method. The process is as follows: First, Ca(NO 3 ) 2 4H 2 O and (NH 2 ) 2 HPO 4 Mix according to the molar ratio of Ca:P=1.85, add distilled water to dissolve, and make the Ca in the solution 2+ The ion concentration is 0.07mol / L; in the solution according to Ca(NO 3 ) 2 4H 2 O and (NH 2 ) 2 HPO 4 Total mass: urea = 1:8 Add urea powder and stir evenly; under magnetic stirring, put the generating head of the multi-frequency sonochemical generator into the above solution, at 50°C, 80°C and 100°C, use 180W ultrasonic Power, carry out sonochemical synthesis for 70 minutes; filter and wash the suspension, first wash it twice with distilled water, then wash it three times with absolute ethanol, put the filtered material into a vacuum drying oven and dry it at 80°C for 18 hours to obtain ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com