Novel nano preparation with stable protein and preparation method and use thereof

A protein and application technology, applied in the direction of medical preparations with non-active ingredients, medical preparations containing active ingredients, pharmaceutical formulas, etc., can solve the problems of small rearrangement and cross-linking, unfavorable production, long time, etc., and achieve a stable shell , stable production and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

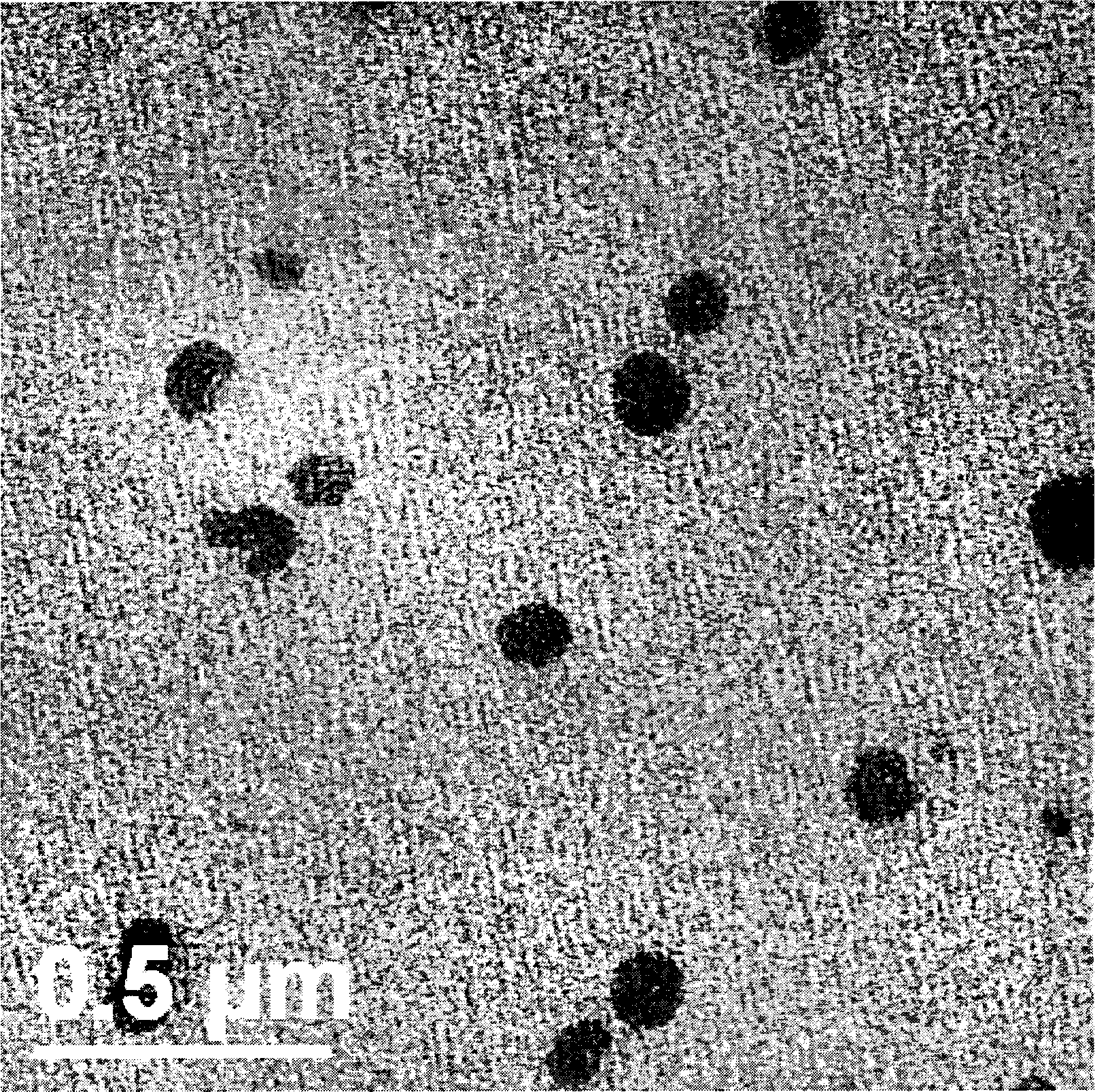

[0032] (prepared by the method of patent 200310123461.X) 30mg paclitaxel (Paclitaxel) was dissolved in 3.0ml dichloromethane, 27.0ml human serum albumin (1%, w / v, the same below) was added to the solution, and the mixture was heated at a low speed Homogenize for 5 minutes to form a coarse emulsion, and then transfer it to a high-pressure homogenizer (Avestin). Evaporate under reduced pressure for 20 minutes at °C to remove chloroform quickly to obtain a translucent dispersion. The average diameter of paclitaxel particles is 190 nm, and freeze-dry for 48 hours without adding any freeze-dried proppant. The obtained cake is easy to reconstitute the original dispersion liquid after adding sterile water or physiological saline, and the particle size after reconstitution is the same as that before freeze-drying, and precipitation occurs after the dispersion liquid is stable for 16 hours.

[0033] (prepared by the method of the present invention) 30mg paclitaxel (Paclitaxel) and 3mg ...

Embodiment 2

[0036] 200mg of paclitaxel (Paclitaxel) was dissolved in 3.7ml of chloroform and 0.3ml of absolute ethanol, added 97.0ml of aqueous solution containing human serum albumin (3%) and sodium dimercaptosuccinate (0.02%), and the mixture was Homogenize for 5 minutes at a rotating speed to form a coarse emulsion, then transfer it to a high-pressure homogenizer, circulate 4 to 5 times for high-pressure homogenization, evaporate the homogenate at 40°C for 20 minutes under reduced pressure, and quickly remove chloroform , to obtain a translucent dispersion, the average diameter of paclitaxel particles is generally 130 ~ 160nm, diluted with water, ultrafiltration with a molecular weight of 10,000 ultrafiltration membrane, the concentrated solution was freeze-dried for 48 hours, without adding any freeze-dried proppant. The obtained cake can easily reconstitute the original dispersion after adding sterile water or physiological saline, and the particle size after reconstitution is the sam...

Embodiment 3

[0038] 200mg paclitaxel (Paclitaxel) and 20mg dimercaptopropanol were dissolved in 3.7ml of chloroform and 0.3ml of absolute ethanol, and 97.0ml of human serum albumin (3%) solution was added, and the mixture was homogenized for 5 minutes at a low speed. To form a crude emulsion, then transfer it to a high-pressure homogenizer, and circulate the high-pressure homogenization for 4 to 5 times. The homogenized liquid is evaporated under reduced pressure at 40°C for 20 minutes, and the chloroform is quickly removed. The obtained dispersion is half Transparent, the average diameter of paclitaxel particles is generally 130-150nm, diluted with water, ultrafiltration with an ultrafiltration membrane with a molecular weight of 10,000, and the concentrated solution was freeze-dried for 48 hours without adding any freeze-dried proppant. The obtained cake can easily reconstitute the original dispersion after adding sterile water or physiological saline, and the particle size after reconsti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com