Magnesium oxide precast refractory material and construction method thereof

A technology of refractory materials and construction methods, applied in the field of refractory materials and their construction, can solve the problems of not meeting the life requirements of continuous casting ladles, long baking time of ladles, easy slag and peeling resistance, etc., so as to avoid advanced damage and improve Resistance to steel slag erosion and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to further describe the present invention, a magnesia prefabricated refractory material and its construction method of the present invention will be further described below in conjunction with examples.

[0029] The embodiment formula of a kind of magnesia quality prefabricated refractory material of the present invention is shown in the following table:

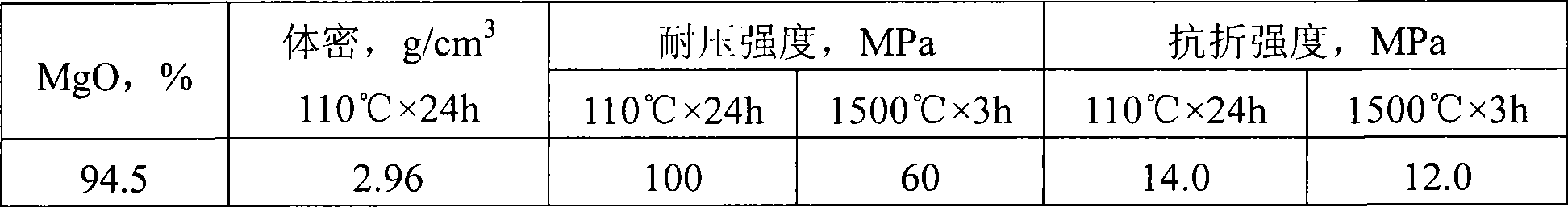

[0030] Table 1 Example formula (% by weight) of a magnesia prefabricated refractory material

[0031] components Example 1 Example 2 Example 3 Example 4 Example 5 Example 6 Magnesia particles 66.85 59 66 72 66 67.6 Magnesia powder 30 30.30 27.55 18 31 28 Silica powder 2 6 4 5.7 2.11 0.5 Aluminum powder 1 4 2 3.95 0.5 3.5 Hexametaphosphate 0.05 0.3 0.2 0.25 0.05 0.15 sodium tripolyphosphate 0.05 0.3 0.2 0.05 0.3 0.2 organic fiber 0.05 0.1 0.05 0.05 0.04 0.05

[0032] A magnesia prefabricated refractory materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com