Production technique of combination type gear

A production process and combined technology, applied in the field of combined gear production technology, can solve the problems of complex processing technology, many processing equipment, long production time, etc., and achieve the effect of simple process, less personnel input, and improved processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A production process of combined gears consists of the following steps:

[0028] Step 1: Weigh 65 kg of iron powder, 25 kg of copper powder, and 10 kg of carbon powder in a mixer and mix them evenly into mixed powders;

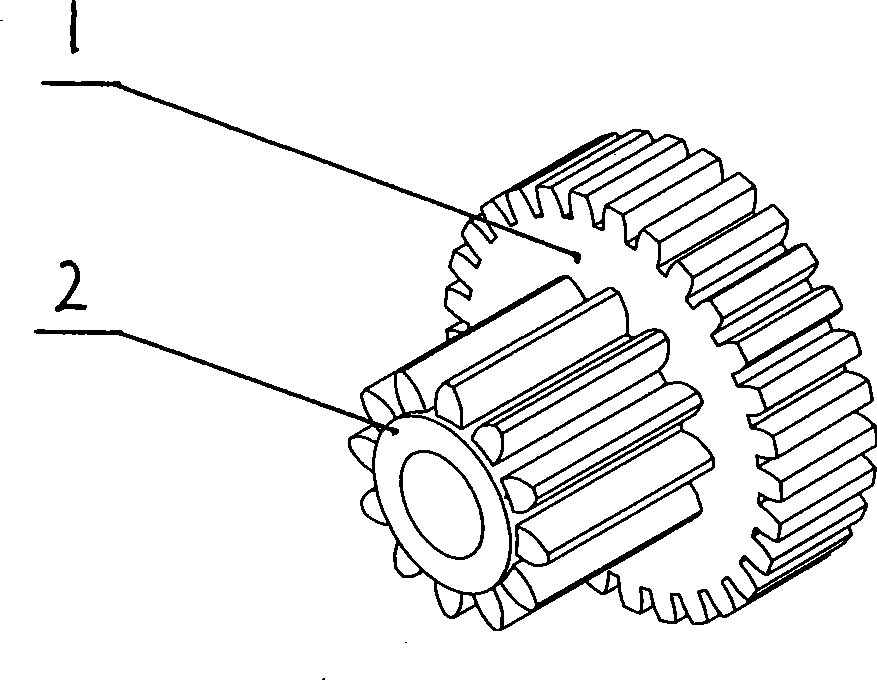

[0029] Step 2: Press the mixed powder through a die casting machine with a pressure of 63 tons and a time of 1 minute to form a combined gear blank (large gear 1, small gear 2);

[0030] Step 3: Put the combined gear blanks (large gear 1, small gear 2) into a high-temperature sintering furnace for high-temperature sintering. The temperature control is first at 650°C for 30 minutes, then the temperature is controlled at 850°C for 60 minutes, and then the temperature is controlled at 1150 ℃, time 150 minutes, finally temperature control 950 ℃, time 60 minutes, then quenching;

[0031] Step 4. Finally, after the surface is blackened, it becomes a CD4 type combined gear product (large gear 1, small gear 2), a total of 8000 pieces.

Embodiment 2

[0033] A production process of combined gears consists of the following steps:

[0034] Step 1: Weigh 65 kg of iron powder, 25 kg of copper powder, and 10 kg of carbon powder in a mixer and mix them evenly into mixed powders;

[0035] Step 2: Press the mixed powder through a die-casting machine with a pressure of 100 tons and a time of 1 minute to form a combined gear blank (large gear 1, small gear 2);

[0036] Step 3: Put the combined gear blanks (large gear 1, small gear 2) into a high-temperature sintering furnace for high-temperature sintering. The temperature control is first at 650°C for 30 minutes, then the temperature is controlled at 850°C for 60 minutes, and then the temperature is controlled at 1150 ℃, time 150 minutes, finally temperature control 950 ℃, time 60 minutes, then quenching;

[0037] Step 4. Finally, after the surface is blackened, it becomes a CD2 type combined gear product (large gear 1, small gear 2), a total of 4000 pieces.

Embodiment 3

[0039] A production process of combined gears consists of the following steps:

[0040] Step 1: Weigh 65 kg of iron powder, 25 kg of copper powder, and 10 kg of carbon powder in a mixer and mix them evenly into mixed powders;

[0041] Step 2: Press the mixed powder through a die casting machine with a pressure of 200 tons and a time of 1 minute to form a combined gear blank (large gear 1, small gear 2);

[0042] Step 3: Put the combined gear blanks (large gear 1, small gear 2) into a high-temperature sintering furnace for high-temperature sintering. The temperature control is first at 650°C for 30 minutes, then the temperature is controlled at 850°C for 60 minutes, and then the temperature is controlled at 1150 ℃, time 150 minutes, finally temperature control 950 ℃, time 60 minutes, then quenching;

[0043] Step 4. Finally, after the surface is blackened, it becomes a CDW type combined gear product (large gear 1, small gear 2), a total of 2000 pieces.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com