Production method of soy sauce

A production method and product technology, applied in food preparation, application, food science and other directions, can solve problems such as heavy taste, and achieve the effects of improving flavor and freshness, ensuring yield, and increasing aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

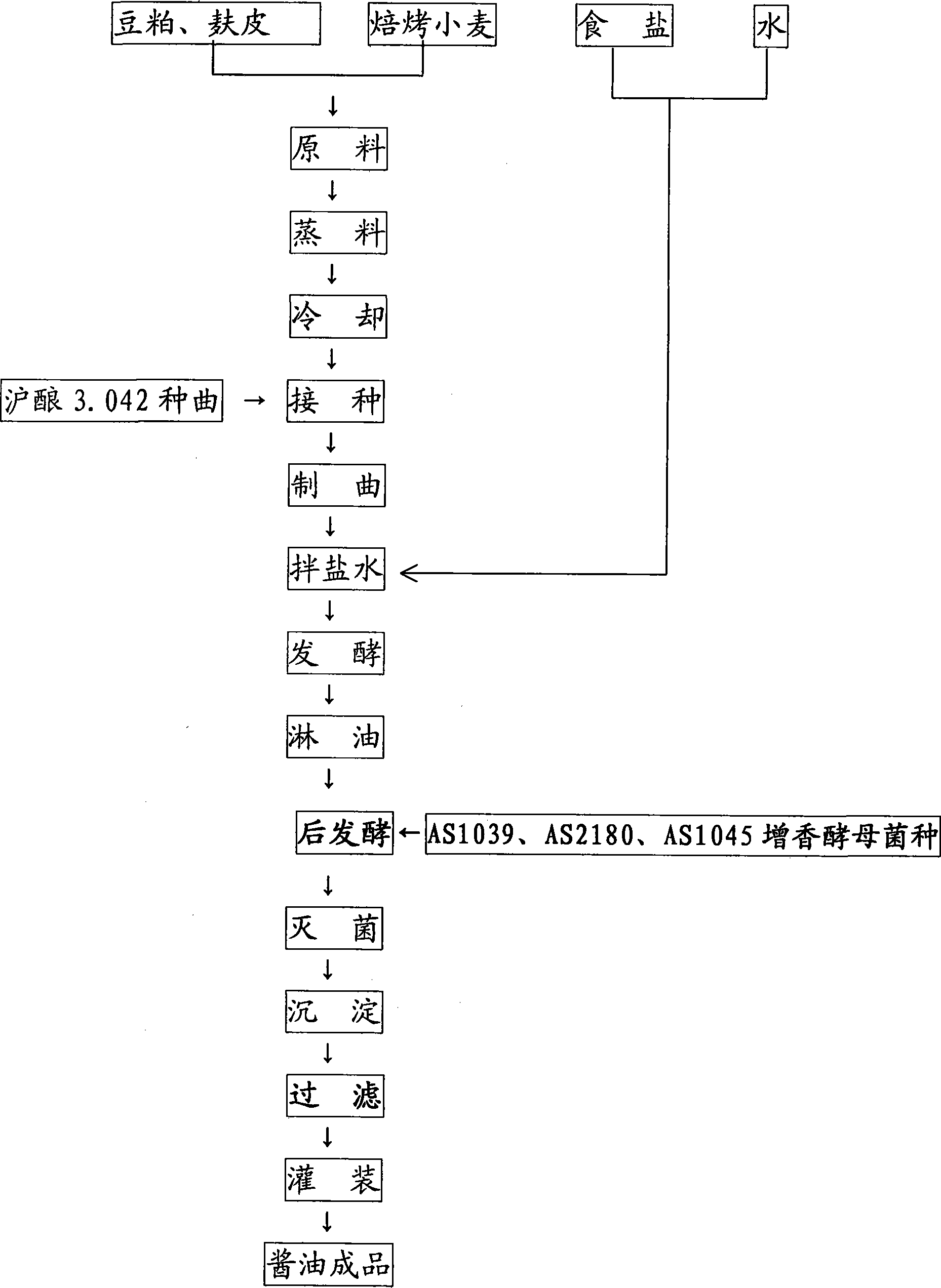

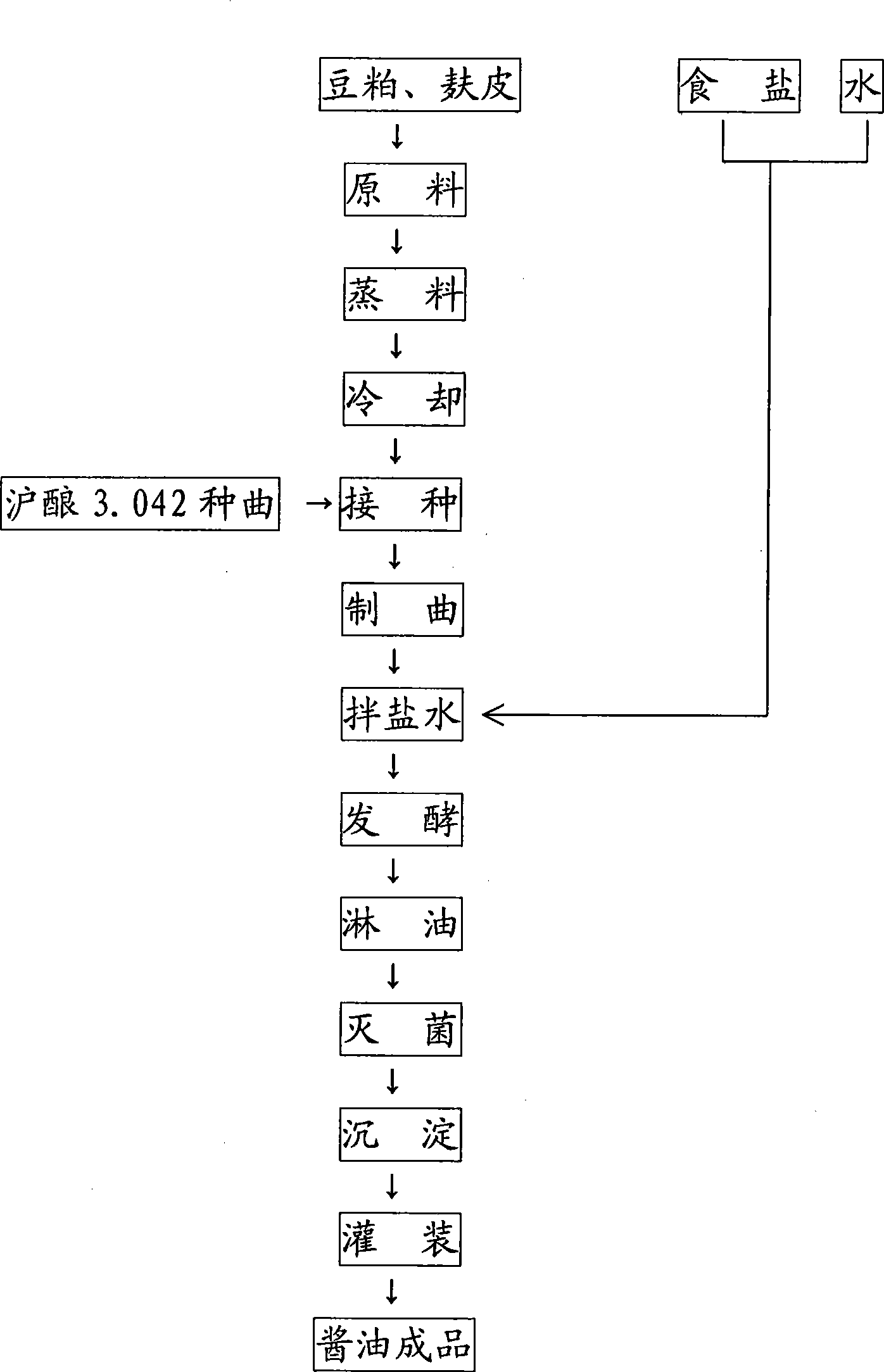

[0052] Below in conjunction with accompanying drawing of specification sheet, the production method of soy sauce product of the present invention is described in detail, just as description attached figure 1 Shown:

[0053] A production method of a soy sauce product, comprising using soybean meal and bran as raw materials in units of weight, the raw material ratio is soybean meal:bran=60:40, and the raw materials are steamed, cooled, inoculated, koji-making, mixed with salt water, The production process of fermenting, pouring oil, sterilizing, precipitating, and filling to obtain the finished product of soy sauce; its main technical characteristics are as follows:

[0054] (1), the raw material: the raw material is a non-transgenic raw material that can guarantee the safety of soy sauce products and a standard raw material that meets the requirements of pesticide residues and harmful heavy metal residues stipulated by green food;

[0055] (1). ①. The particle diameter of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com