A core-shell type silicon-containing synergistic flame retardant and preparation method thereof

A technology of synergistic flame retardants and flame retardants, applied in the field of flame retardants, can solve the problems of high production costs, limited coating effect, and staying in the laboratory stage, etc., to achieve improved processing performance, good recycling effect, The effect of meeting strict requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

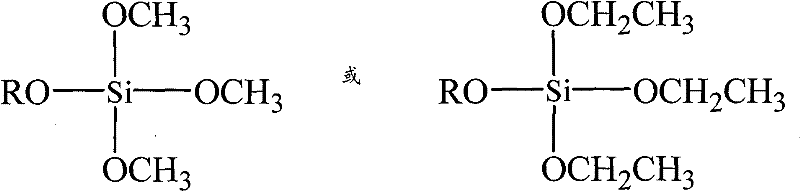

Embodiment 1

[0026] Add 50ml of deionized water and 150ml of ethanol to a reaction kettle equipped with a stirring and reflux device. After stirring evenly, add 50g of ammonium polyphosphate and 1g of OP-10, heat to 45°C while stirring, and add concentrated ammonia water to adjust the pH value to 9. ~11, then slowly add 5g of organosilicon oxide compound dropwise at a rate of 3ml / min, stir for 150min, then lower the reaction kettle to room temperature, filter, wash, and dry the filter cake at 120°C and 30mmHg to obtain 51.4 g of the core-shell silicon-containing synergistic flame retardant product of the present invention with good fluidity.

[0027] If other conditions remain unchanged, the flame retardant ammonium polyphosphate in this embodiment is replaced by antimony trioxide, aluminum hydroxide, magnesium hydroxide, aluminum oxalate, calcium aluminate, calcium carbonate, hydroxide Inorganic flame retardants including calcium, zinc borate, borax, expanded graphite or red phosphorus; ...

Embodiment 2

[0029] Add 50ml of deionized water and 150ml of ethanol to a reaction kettle equipped with a stirring and reflux device. After stirring evenly, add 50g of ammonium polyphosphate and 1g of OP-10, heat to 45°C while stirring, add concentrated ammonia water, and adjust the pH value at 9 to 11, then slowly add 7.5g of organosilicon oxide compound dropwise at a rate of 5ml / min, the dropwise addition is completed within 25 minutes, and the reaction is stirred for 180 minutes, then the reactor is lowered to room temperature, filtered, washed, and the filter cake is Dry at 120°C and 30mmHg to obtain 52.6g of the core-shell silicon-containing synergistic flame retardant product of the present invention with good fluidity.

Embodiment 3

[0031] Add 50ml of deionized water and 150ml of ethanol to a reaction kettle equipped with a stirring and reflux device. After stirring evenly, add 50g of ammonium polyphosphate and 1g of OP-10, heat to 45°C while stirring, add concentrated ammonia water, and adjust the pH value at 9 to 11, then slowly add 10 g of organosilicon oxide compound dropwise at a rate of 3 ml / min, stir for reaction, after reacting for 330 minutes, cool, filter, wash, and dry the filter cake at 120°C and 30 mmHg to obtain 53.3 g of free The core-shell silicon-containing synergistic flame retardant product of the invention has good fluidity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com