Method for processing electroplating waste containing Ni2+, Zn2+ and Cr3+

A technology for electroplating wastewater and treatment methods, which is applied in the fields of metallurgical wastewater treatment, water/sewage treatment, water/sludge/sewage treatment, etc. Increase the amount of mud and other problems to achieve the effect of self-purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment one: the process and steps in this embodiment are as follows:

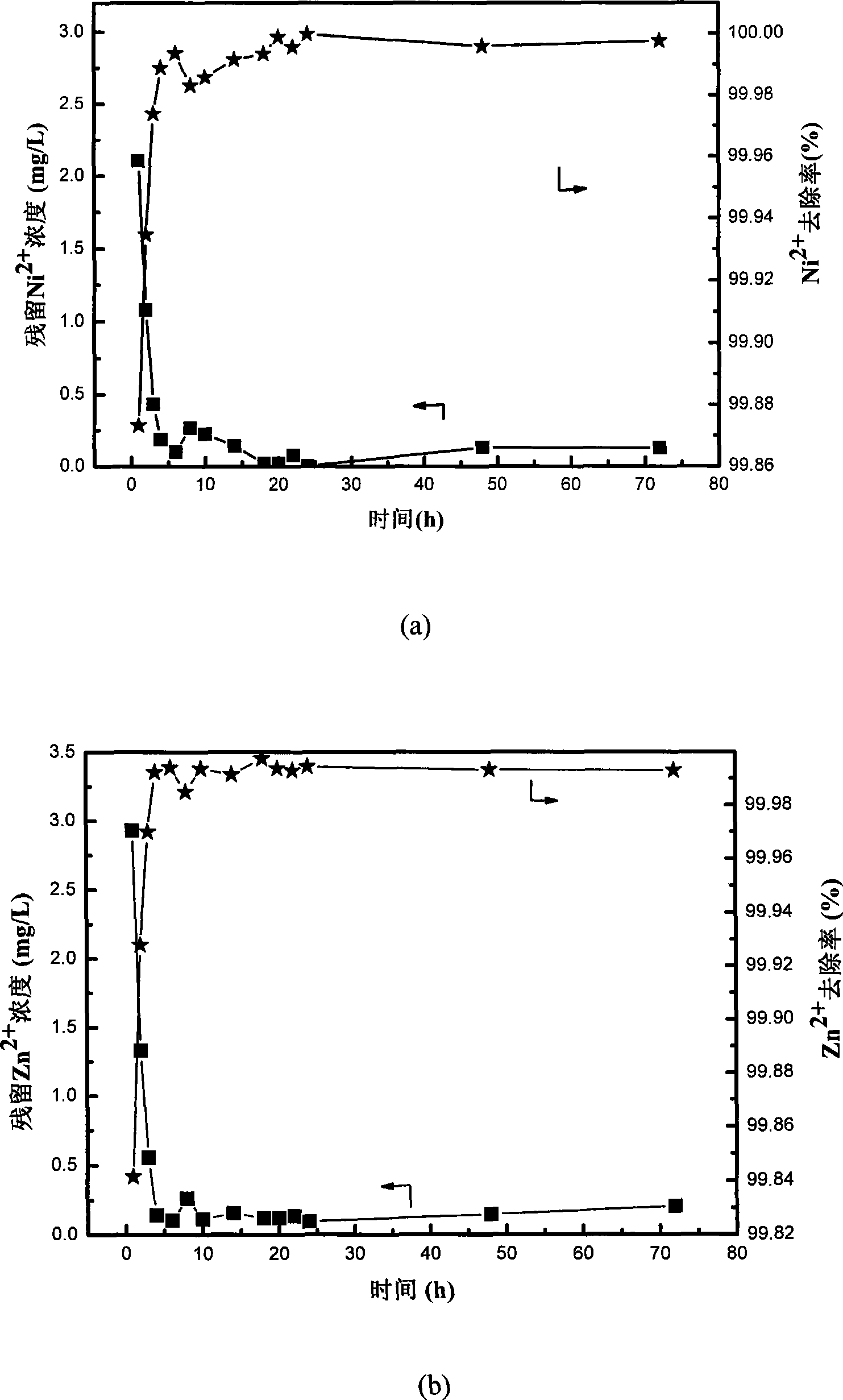

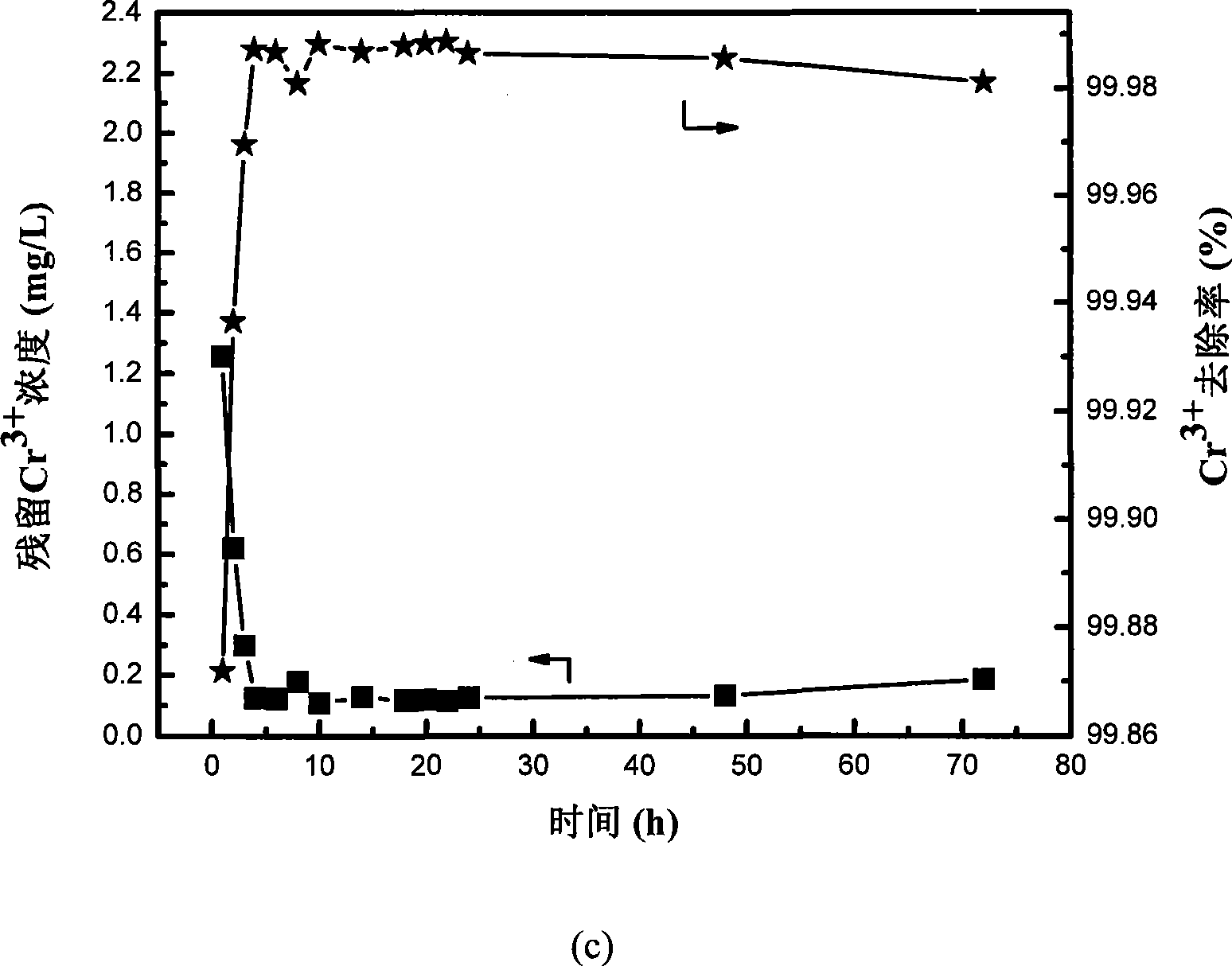

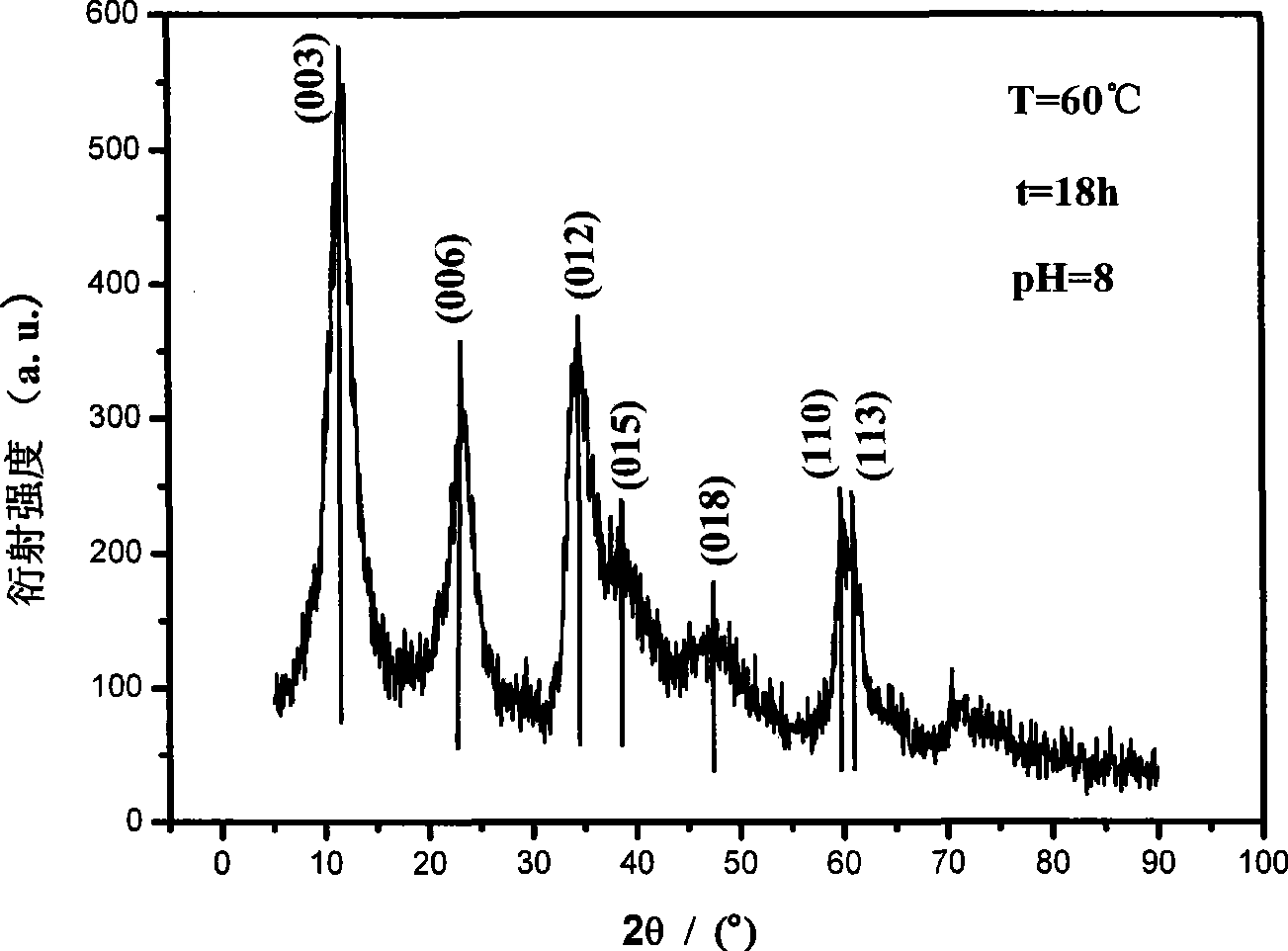

[0017] (1) Weigh a certain amount of Ni-containing 2+ , Zn 2+ 、Cr 3+ Dissolve electroplating wastewater and a certain amount of sodium hydroxide in water to form a solution; first add 50ml of deionized water to the reactor, and then put it in a constant temperature water pot at 60°C for heating; use a constant current pump to mix electroplating wastewater and hydrogen The sodium oxide solution is slowly transported into the reactor; the Ni in the wastewater 2+ , Zn 2+ 、Cr 3+ The ratio of the molar mass of heavy metal ions to the molar mass of sodium hydroxide is controlled at 1:1; at the same time, CO is delivered to the reactor 2 gas, and controlled at a pH of 8.5; during the reaction, use a booster electric stirrer to stir the reaction solution, and make the CO 2 The aeration volume is constant; after the electroplating wastewater reacts, stop feeding CO 2 , then accelerated the stirring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com