Method for producing tellurium dioxide by self-purification of crude tellurium powder

A tellurium dioxide, self-purification technology, applied in the direction of selenium/tellurium oxide/hydroxide, binary selenium/tellurium compound, etc., can solve the problems of long process and low recovery rate, achieve short process and shorten the process flow , the effect of reducing the content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

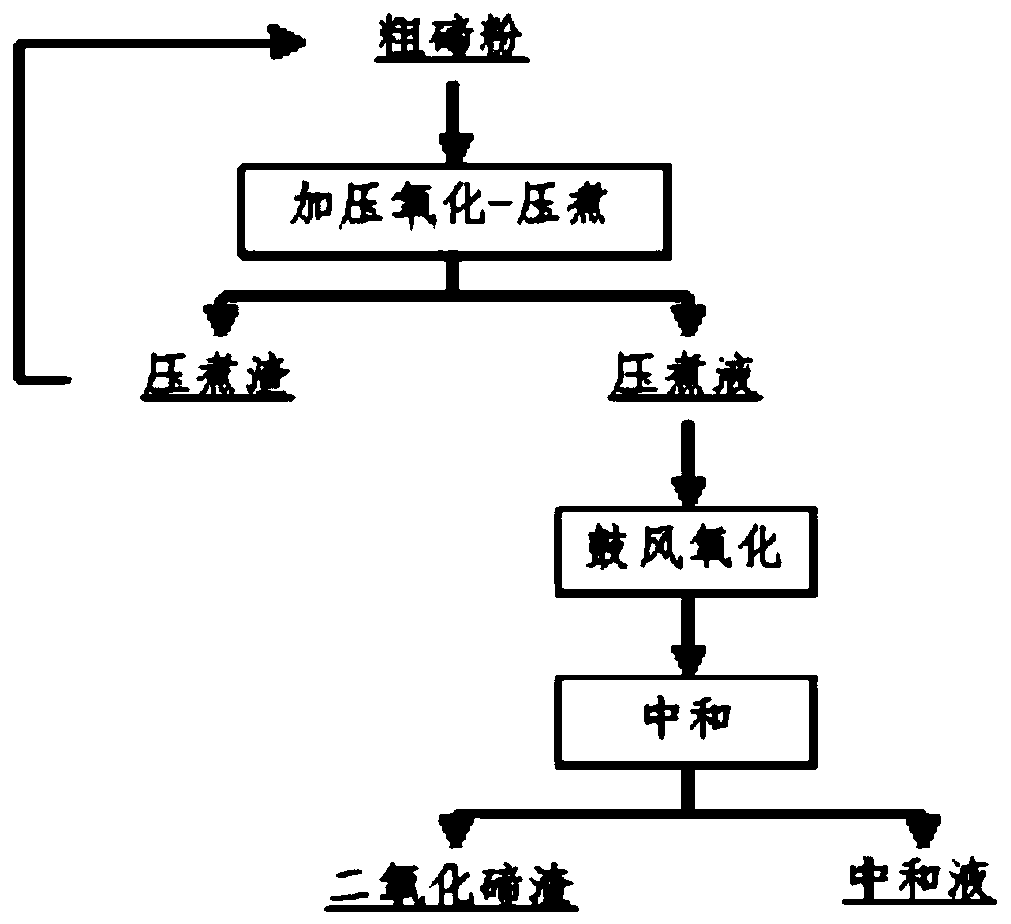

Image

Examples

Embodiment 1

[0048] The coarse tellurium powder derived from copper and lead anode mud generally contains a small amount of impurities such as Cu, Pb, Bi, Sb, Ag, Na, and Se. Impurities such as Cu, Pb, Bi, Sb, Na, etc. can be preliminarily separated by washing with a small amount of oxidant in the hydrochloric acid medium; the oxide slag (tellurium dioxide slag) produced has a higher impurity content, and the subsequent purification to produce 4N tellurium requires alkali Processes such as leaching and purification are subjected to further impurity removal treatment, the process flow is long, there are many side reactions in the process, and the yield of tellurium is low and unstable. In this scheme, the crude tellurium powder is subjected to pressure oxidation-autoclave treatment under alkaline conditions, the reaction temperature is controlled at 110°C, the pressure oxidation time is 100 min, the autoclave time is 100 min, and the alkalinity of the reaction system is 57 g / l; After the com...

Embodiment 2

[0050] The coarse tellurium powder derived from copper and lead anode mud generally contains a small amount of impurities such as Cu, Pb, Bi, Sb, Ag, Na, and Se. Impurities such as Cu, Pb, Bi, Sb, Na, etc. can be preliminarily separated by washing with a small amount of oxidant in the hydrochloric acid medium; the oxide slag (tellurium dioxide slag) produced has a higher impurity content, and the subsequent purification to produce 4N tellurium requires alkali Processes such as leaching and purification are subjected to further impurity removal treatment, the process flow is long, there are many side reactions in the process, and the yield of tellurium is low and unstable. In this scheme, under alkaline conditions, the crude tellurium powder is subjected to pressure oxidation-autoclave treatment, the reaction temperature is controlled to 100 ℃, the pressure oxidation time is 40 min, the autoclave time is 20 min, and the alkalinity of the reaction system is 60 g / l; After the comp...

Embodiment 3

[0052] The coarse tellurium powder derived from copper and lead anode mud generally contains a small amount of impurities such as Cu, Pb, Bi, Sb, Ag, Na, and Se. Impurities such as Cu, Pb, Bi, Sb, Na, etc. can be preliminarily separated by washing with a small amount of oxidant in the hydrochloric acid medium; the oxide slag (tellurium dioxide slag) produced has a higher impurity content, and the subsequent purification to produce 4N tellurium requires alkali Processes such as leaching and purification are subjected to further impurity removal treatment, the process flow is long, there are many side reactions in the process, and the yield of tellurium is low and unstable. In this scheme, the crude tellurium powder is subjected to pressure oxidation-autoclave treatment under alkaline conditions, the reaction temperature is controlled at 90°C, the pressure oxidation time is 20 min, the autoclave time is 40 min, and the alkalinity of the reaction system is 65 g / l; After the comple...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com