A method of performing model-based scanner tuning

A scanner and imaging model technology, which can be used in instruments, photolithography process of pattern surface, microlithography exposure equipment, etc., can solve the problems of time-consuming, expensive, and achieve low-cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

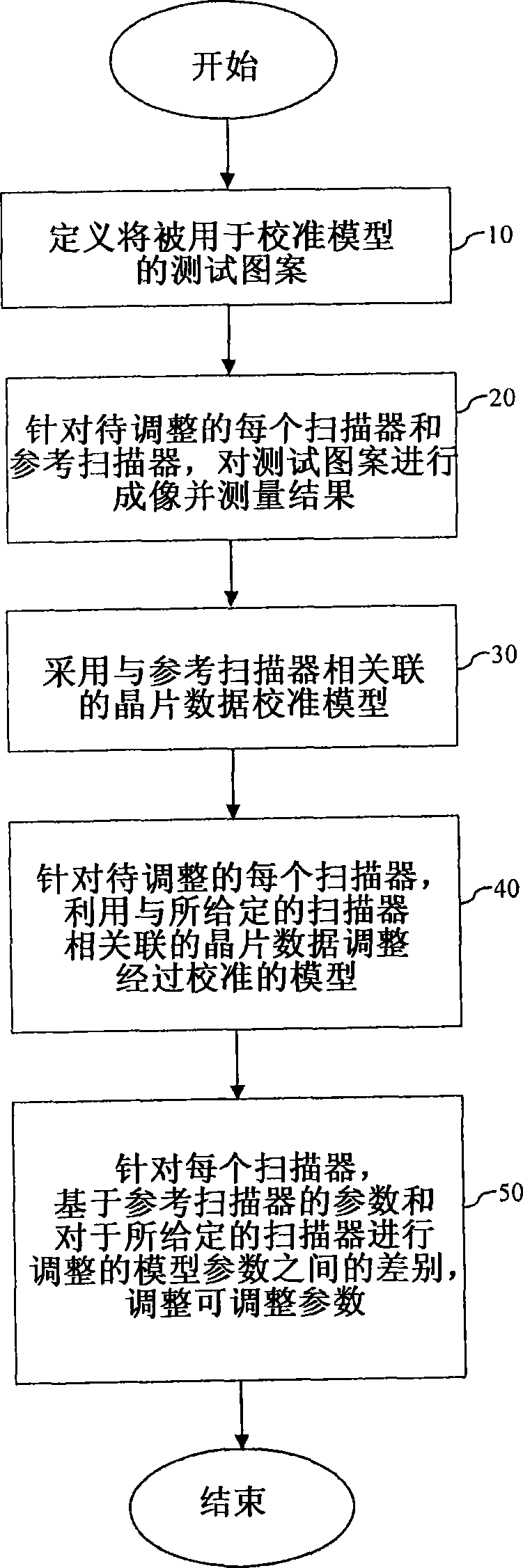

[0031] figure 1 is an exemplary flowchart representing the model-based scanner tuning method of the present invention. As explained in detail below, the method of the present invention allows simultaneous optimization of imaging performance and OPE matching between different lithographic systems comprising scanners for imaging the same target pattern .

[0032] refer to figure 1 , the first step in the process (step 10) is to define a test pattern for calibrating the model of the reference scanner. Suitable test patterns (also known as phantom calibration metric patterns) can be used. The test pattern employed should sufficiently represent the features to be imaged so that it is possible to generate a robust model capable of accurately predicting the imaging performance of the lithography system. Such test patterns can be easily generated / selected by one skilled in the art once the target pattern or application is determined. It should be noted that it is also possible to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com