Multicomponent rare earth boride (LaxRE1-x)B6 cathode material and preparation thereof

A rare earth boride and cathode material technology, applied in the direction of boron/boride, metal boride, etc., can solve the problems of high sintering temperature, complex process, and less component system, and achieve low sintering temperature, simple process, and high density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

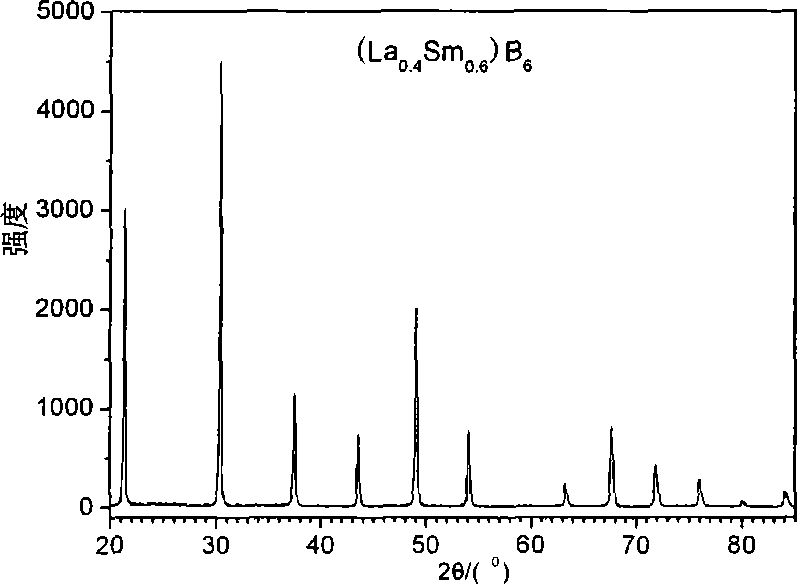

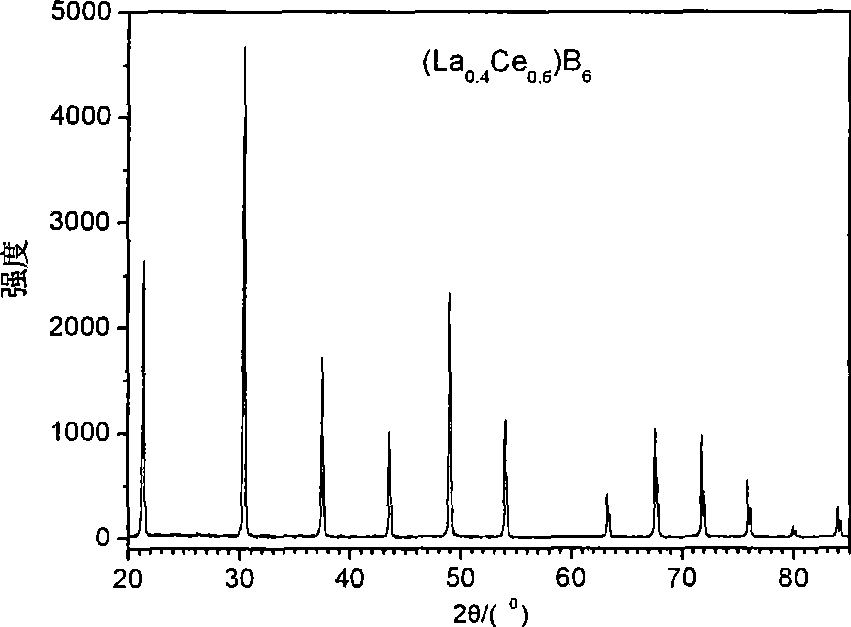

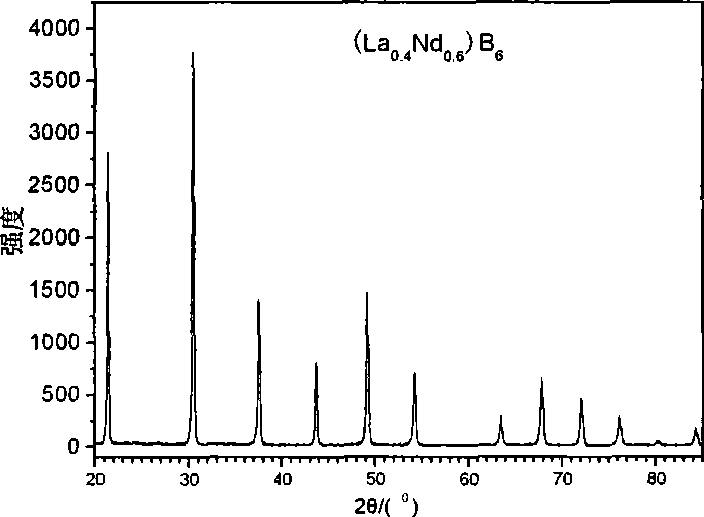

Image

Examples

Embodiment 1

[0019] 1) DC arc evaporation and condensation equipment is adopted, with elemental rare earth metal La block as anode and metal tungsten as cathode, in an atmosphere with a volume ratio of hydrogen to argon of 2:1 and a total pressure of 0.1MPa, the reaction current is 40A, and the anode The voltage between the cathode and the cathode is 50V, and the reaction time is 30min to prepare 10-30nm LaH 2 Nano powder;

[0020] 2) DC arc evaporation and condensation equipment is used, with single rare earth metal Sm block as anode and metal tungsten as cathode, in an atmosphere with a volume ratio of hydrogen to argon of 2:1 and a total pressure of 0.1MPa, the reaction current is 40A, and the anode The voltage between the cathode and the cathode is 50V, the reaction time is 30min, and the SmH of 10-30nm is prepared 2 Nano powder;

[0021] 3) LaH 2 Nano powder, SmH 2 Nano-powder and B powder (20-40nm) are ground and mixed in an argon atmosphere with an oxygen content of 30ppm at a m...

Embodiment 2

[0025] 1) DC arc evaporation and condensation equipment is adopted, with elemental rare earth metal La block as anode and metal tungsten as cathode, in an atmosphere with a volume ratio of hydrogen to argon of 3:1 and a total pressure of 0.1MPa, the reaction current is 80A, and the anode The voltage between the cathode and the cathode is 30V, and the reaction time is 30min to prepare 20-40nm LaH 2 Nano powder;

[0026] 2) DC arc evaporation and condensation equipment is adopted, the single rare earth metal Sm block is used as the anode, and the metal tungsten is used as the cathode. In an atmosphere with a volume ratio of hydrogen and argon of 3:1 and a total pressure of 0.1MPa, the reaction current is 80A, and the anode The voltage between the cathode and the cathode is 30V, the reaction time is 30min, and the SmH of 20-40nm is prepared 2 Nano powder;

[0027] 3) LaH 2 Nano powder, SmH 2 Nano-powder and B powder (20-40nm) are ground and mixed in an argon atmosphere with a...

Embodiment 3

[0031] 1) DC arc evaporation and condensation equipment is adopted, with elemental rare earth metal La block as anode and metal tungsten as cathode, in an atmosphere with a volume ratio of hydrogen to argon of 4:1 and a total pressure of 0.1MPa, the reaction current is 60A, and the anode The voltage between the cathode and the cathode is 40V, and the reaction time is 30min to prepare 20-30nm LaH 2 Nano powder;

[0032] 2) DC arc evaporation and condensation equipment is adopted, with single rare earth metal Sm block as anode and metal tungsten as cathode, in an atmosphere with a volume ratio of hydrogen to argon of 4:1 and a total pressure of 0.1MPa, the reaction current is 60A, and the anode The voltage between the cathode and the cathode is 40V, the reaction time is 30min, and the SmH of 20-30nm is prepared 2 Nano powder;

[0033] 3) LaH 2 Nano powder, SmH 2 Nano powder and B powder (1-20 μm) are ground and mixed in an argon atmosphere with an oxygen content of 100 ppm a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com