Method for directly separating and extracting leaf protein of heart trefoil for feeding and eating

An extraction method and leaf protein technology, applied in the field of alfalfa leaf protein extraction, can solve problems such as secondary processing, and achieve the effects of accelerating industrial upgrading, broad development prospects, and alleviating serious deficiencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

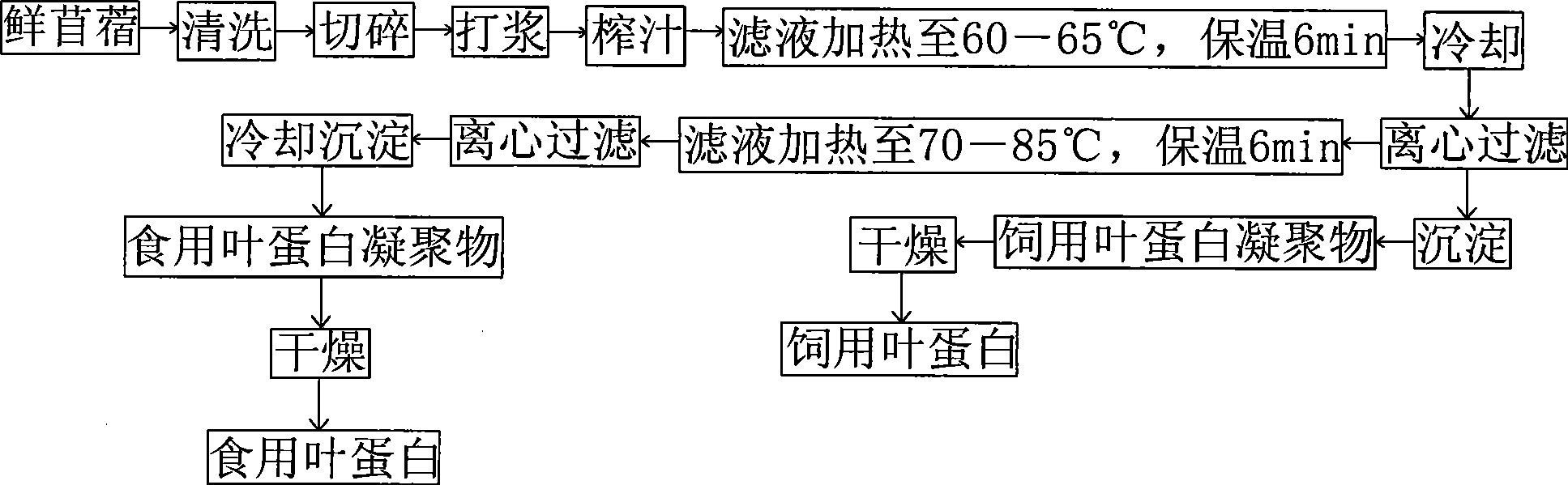

Image

Examples

Embodiment 1

[0024] (1) Processing raw materials: use fresh alfalfa, take its top 30cm and plant leaves as processing raw materials, alfalfa should be processed as soon as possible after harvesting, if it needs to be stored for a short time, it should be sealed in a fresh-keeping bag and placed at 5 °C Refrigerate left and right, so as not to reduce the yield and quality of alfalfa leaf protein due to the action of the leaf itself and microbial contamination;

[0025] (2) Cleaning, crushing, beating and juicing: Clean the alfalfa, drain the water, cut into small pieces of 0.5-1cm, add water according to the ratio of raw material: water = 1:2 by weight, and put it into a tissue masher Uniform beating, filtering and squeezing with 120-mesh nylon filter cloth to obtain alfalfa juice;

[0026] (3) Leaf protein aggregation: use a water bath to gradually increase the temperature, first raise the temperature of the alfalfa juice to 60°C, keep it warm for 6 minutes, filter or centrifuge to obtain ...

Embodiment 2

[0031] (1) processing raw material: adopt fresh alfalfa, get its top 30cm and plant blade as processing raw material;

[0032] (2) Cleaning, crushing, beating and juicing: Clean the alfalfa, drain the water, cut into small pieces of 0.5-1cm, add water according to the ratio of raw material: water = 1:2 by weight, and put it into a tissue masher Uniform beating, filtering and squeezing with 120-mesh nylon filter cloth to obtain alfalfa juice;

[0033] (3) Leaf protein aggregation: use a water bath to gradually increase the temperature, first raise the temperature of the alfalfa juice to 60°C, keep it warm for 6 minutes, filter or centrifuge to obtain green fodder leaf protein aggregates; then heat the filtrate or supernatant to 80°C, keep warm 6min, filter to obtain white edible leaf protein aggregate;

[0034] (4) Separation of leaf protein aggregates: use filter cloth to filter, so that edible leaf protein aggregates and forage leaf proteins are separated from water respecti...

Embodiment 3

[0038] (1) Processing raw materials: use fresh alfalfa, take its top 30cm and plant leaves as processing raw materials, alfalfa should be processed as soon as possible after harvesting, if it needs to be stored for a short time, it should be sealed in a fresh-keeping bag and placed at 5 °C Refrigerate left and right, so as not to reduce the yield and quality of alfalfa leaf protein due to the action of the leaf itself and microbial contamination;

[0039] (2) Cleaning, crushing, beating and juicing: Clean the alfalfa, drain the water, cut into small pieces of 0.5-1cm, add water according to the ratio of raw material: water = 1:2 by weight, and put it into a tissue masher Uniform beating, filtering and squeezing with 120-mesh nylon filter cloth to obtain alfalfa juice;

[0040] (3) Leaf protein aggregation: use a water bath to gradually increase the temperature, first raise the temperature of the alfalfa juice to 60°C, keep it warm for 6 minutes, filter or centrifuge to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com