Manufacturing method of small-bending-radius ultrathin-wall pipe

A technology of bending radius and manufacturing method, which is applied in the field of ultra-thin-walled pipe fittings manufacturing with small bending radius, can solve the problems of high product rejection rate, large deformation of tube blank, inner ring wrinkles, etc., and achieve high material utilization rate and complex shape of components , the effect of fewer processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Below in conjunction with accompanying drawing and specific embodiment, further illustrate the present invention, present embodiment implements under the premise of technical solution of the present invention, should be understood that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

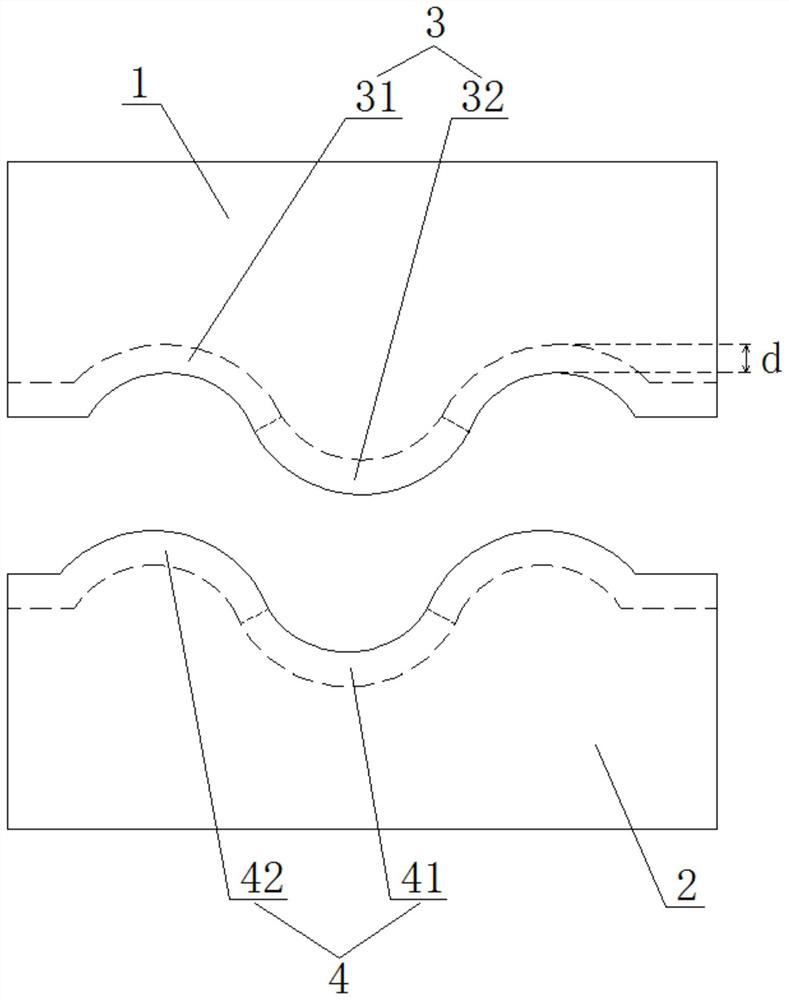

[0025] Such as figure 1 As shown, the embodiment of the present invention provides a method for manufacturing an ultra-thin-wall pipe with a small bending radius, including: customizing the mold according to the bending radius, bending angle and outer diameter of the pipe to be manufactured. Wherein, as shown in Figure 1, the mold of the present invention includes a movable mold 1 and a static mold 2, and the opposite sides of the movable mold 1 and the static mold 2 are respectively provided with a movable mold cavity 3 and a static mold cavity 4, and the pipe fittings are finally placed on the movable mold...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com