Plate-type heat-pipe radiator and use thereof

A plate heat pipe and radiator technology, applied in indirect heat exchangers, instruments, electric solid devices, etc., can solve the problems of large air eddy current loss, reduced working medium circulation area, and high price, so as to reduce air flow resistance and heat transfer Improve and increase the effect of air flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

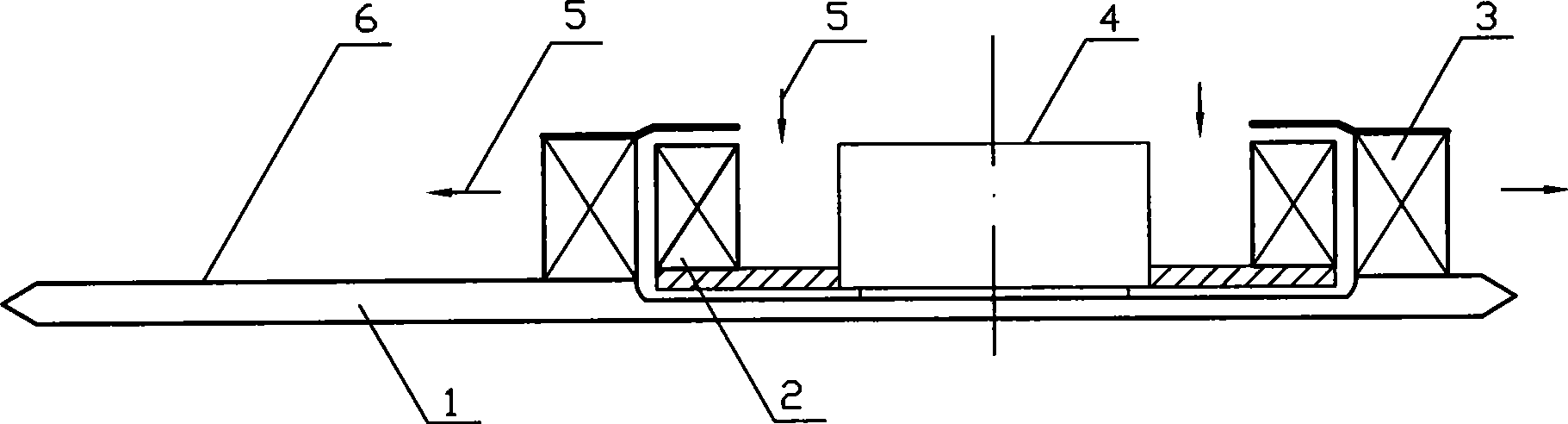

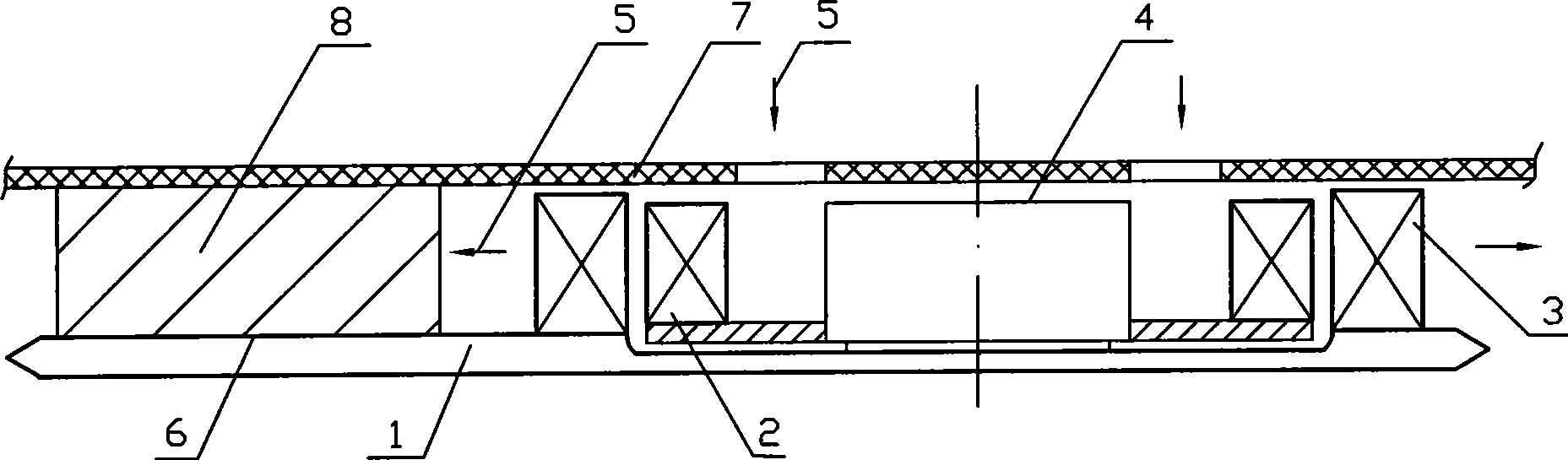

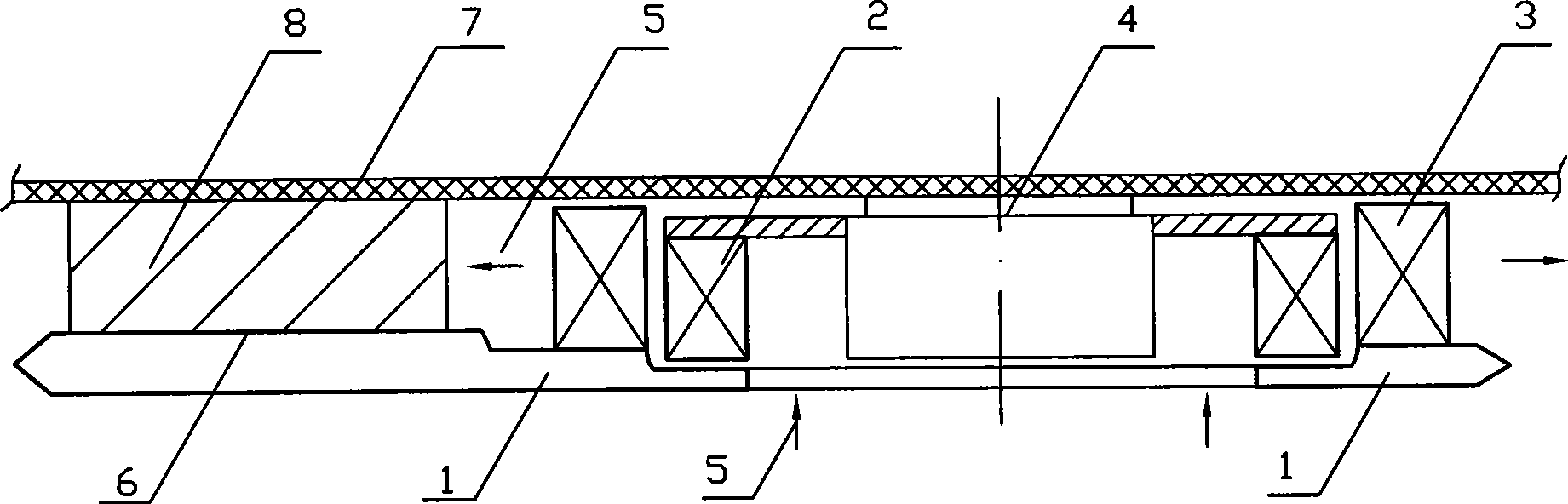

[0030] figure 1 The typical features of the radiator of the present invention are shown. The fan 4 is a centrifugal type with axial air intake and radial outflow. The outer circumference of the impeller 2 of the fan 4 is an air outlet, and the air convection expansion heat exchange surface 3 faces the impeller 2 air outlet, the air driven by the impeller 2 directly enters the air convection expansion heat exchange surface 3. The heat pipe 1 has a plate structure, and the air convection heat exchange surface 3 is directly arranged on the heat pipe 1, and the heat absorption surface 6 is next to it. Where the fan is located, the heat pipe is designed with a concave shape, so that the height of the blades of the impeller 2 and the height of the motor can be increased without increasing the thickness of the radiator, and the air flow of the fan can be increased. In order to prevent the hot air discharged from the radiator from flowing back to the fan intake and reduce the heat dissi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com