Process and apparatus for preparing absolute ethyl alcohol

A technology of absolute ethanol and process methods, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc., can solve problems such as high energy consumption and complicated process flow, and achieve the effect of saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

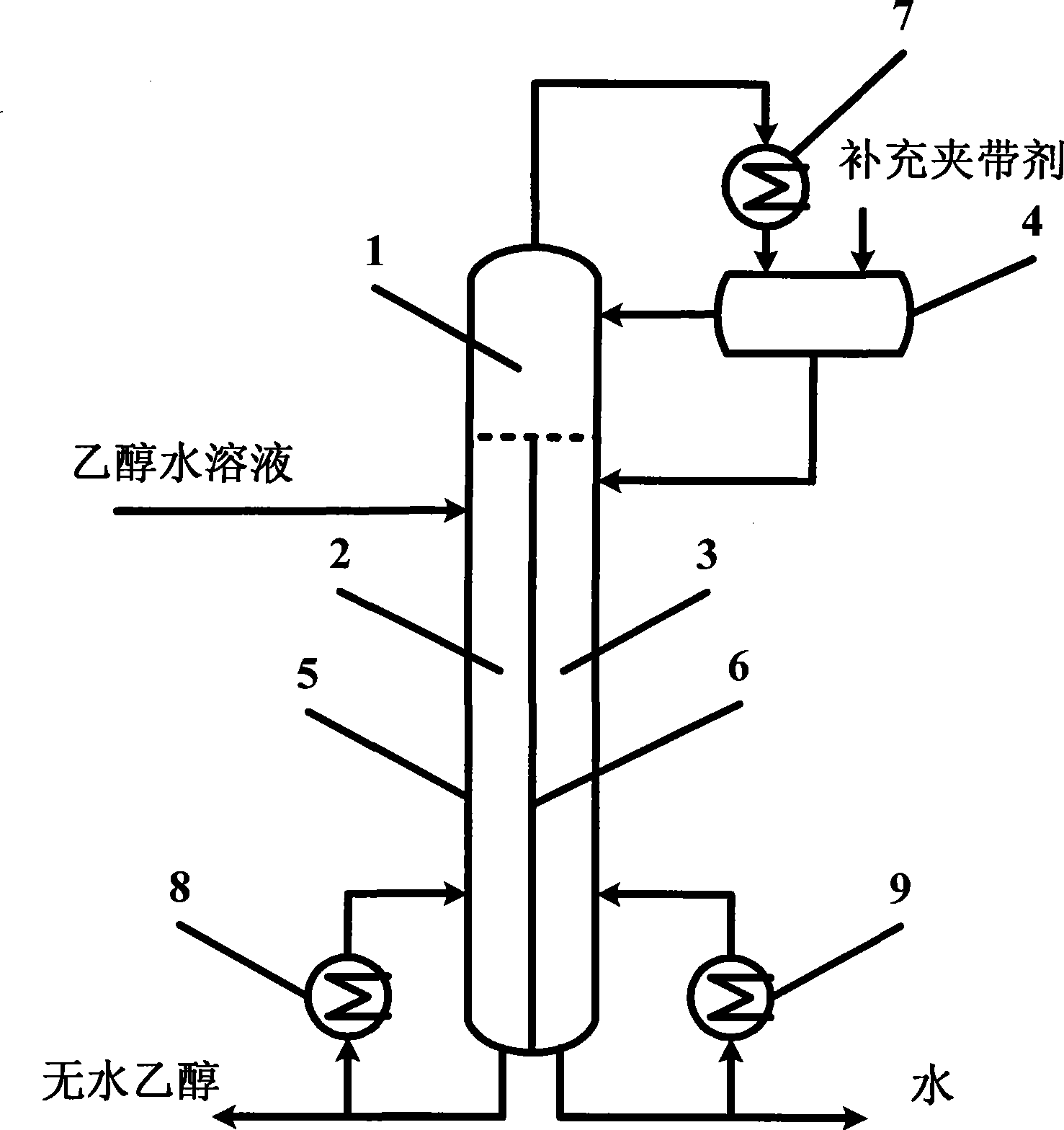

[0019] Example 1: if figure 1 process shown. The azeotropic rectification dividing wall column (5) is a tray column with a diameter of 1000mm and a height of 31000mm. Wherein the number of trays in the public rectification section (1) is 5, the number of trays in the dehydration section (2) is 60, and the number of trays in the side stripping section (3) is 54. The ratio of the cross-sectional area of the dehydration section (2) to the side stripping section (3) is 1.38:1, and the mass flow ratio of the liquid entering the dehydration section (2) to the side stripping section (3) is 12.11:1. In this example, cyclohexane is used as entrainer, and the raw material ethanol aqueous solution feed position (counting from top to bottom, the same below) is the 8th tray of dehydration section (2), the heavy phase in the phase separator (4) The reflux feed position is the first tray of the side stripping section (3), and the supplementary entrainer is added from the phase separator ...

example 2

[0022] Example 2: if figure 1 process shown. The azeotropic rectification dividing wall column (5) is a tray and packing mixed tower with a diameter of 1200mm and a height of 30000mm, wherein the public rectification section (1) uses packing, and the height of the packing layer is 1000mm. The dehydration section (2) and the side line The stripping section (3) uses trays, wherein the number of trays in the dehydration section (2) is 60, and the number of trays in the side stripping section (3) is 54. The ratio of the cross-sectional area of the dehydration section (2) to the side stripping section (3) is 1.31:1, and the mass flow ratio of the liquid entering the dehydration section (2) to the side stripping section (3) is 10.60:1. Feed heat state, feed composition, feed flow rate are the same as example 1, and entrainer is still hexanaphthene, but feed position changes to some extent, and feed position is the 10th tray of dehydration section (2), each stream The flow rate a...

example 3

[0025] Example 3: if figure 1 process shown. The azeotropic rectification dividing wall column (5) is a tray column with a diameter of 1000mm and a height of 31000mm. Wherein the number of trays in the public rectification section (1) is 5, the number of trays in the dehydration section (2) is 60, and the number of trays in the side stripping section (3) is 54. The ratio of the cross-sectional area of the dehydration section (2) to the side stripping section (3) is 1.57:1, and the mass flow ratio of the liquid entering the dehydration section (2) to the side stripping section (3) is 8.80:1. Feed heat state, feed flow are the same as example 1, entrainer is still hexanaphthene, just the ethanol content in the feed becomes 92% (mass fraction), feed position is the 12th block tower of dehydration section (2) The flow rate and composition of each stream are shown in Table 3. The temperature at the top of the tower is 68.5°C, the pressure is 0.12MPa, the temperature of the bot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com