Quartz tuning-fork resonator

A tuning fork resonator and quartz technology, applied in the field of resonators, can solve the problems of poor impact resistance, short service life, mutual influence, etc., and achieve the effects of long service life, enhanced impact resistance, and low vibration frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

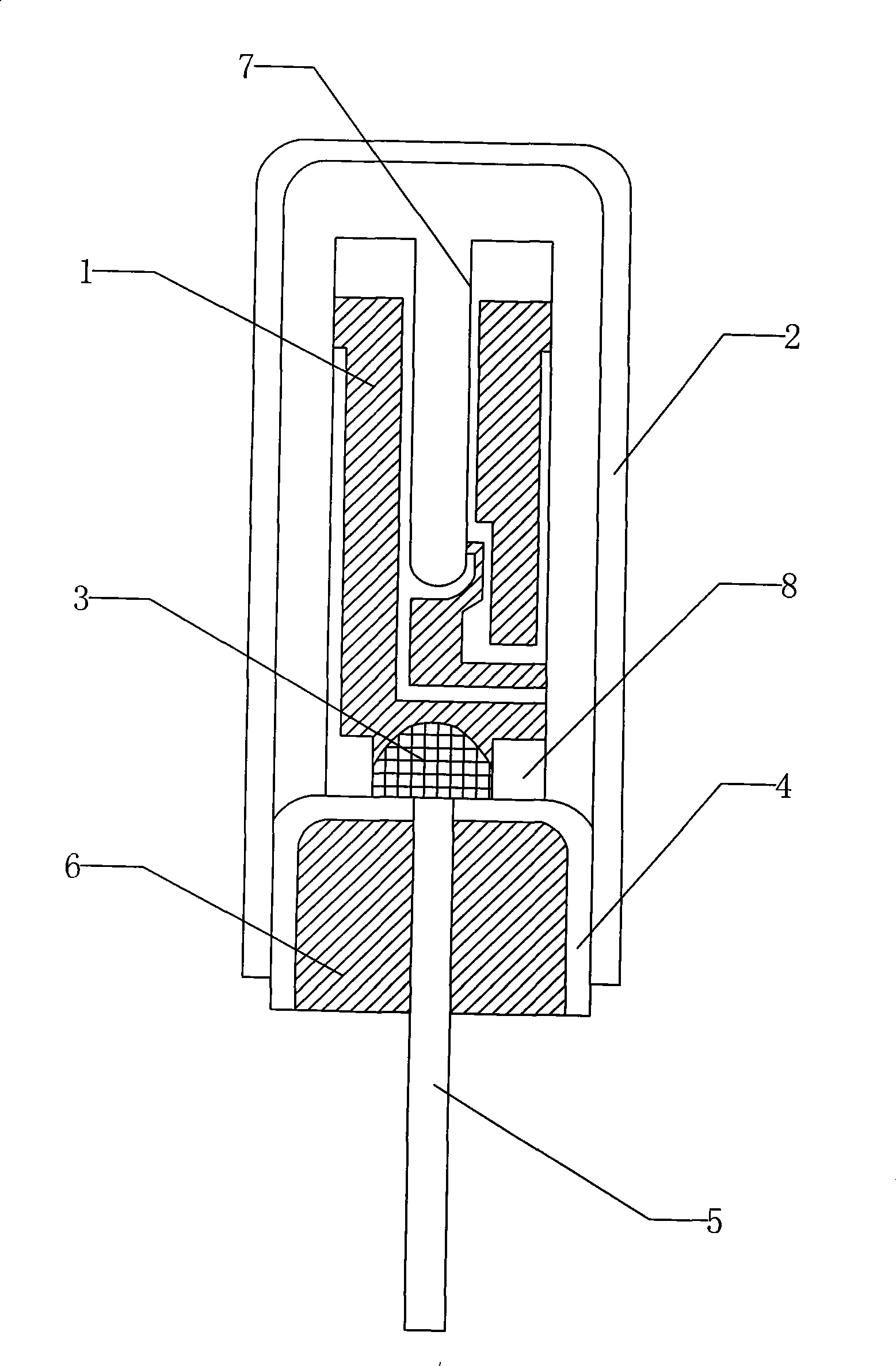

[0011] Such as figure 1 As shown, the quartz tuning fork resonator according to the embodiment of the present invention includes a quartz wafer 1, a shell 2, a solder wire 3, a Kovar ring 4, a lead wire 5, a glass bead 6 and two tuning fork arms 7. The shell 2 is made of zinc cupronickel It is made of material, the tuning fork arm 7 is placed inside the housing 2, and the two tuning fork arms 7 are respectively provided with uniformly distributed quartz wafers 1, and the middle joint of the two tuning fork arms 7 is in the shape of a semi-circular arc; the lower part of the tuning fork arm 7 A solder wire 3 is embedded in the center of the bottom 8 of the tuning fork, and the lower end of the solder wire 3 is connected to a lead 5, which can drive the resonance of the entire resonator when connected to an external device; between the bottom 8 of the tuning fork and the glass bead 6 on the lower side Kovar ring 4, glass beads 6 are set in the Kovar ring 4, the side of the Kovar rin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com