Non-complementary chop controlling intelligent AC voltage-stabilizing and pressure regulating method and device

An AC voltage stabilization, non-complementary technology, applied in control/regulating systems, regulating electrical variables, instruments, etc., can solve problems such as large consumption of non-ferrous metal materials, damage to output voltage waveforms, and low degree of intelligent processing of system control signals. , to achieve the effect of improving the level of electromagnetic compatibility, enhancing circuit reliability, and improving timing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with the examples, but not as a limitation to the present invention.

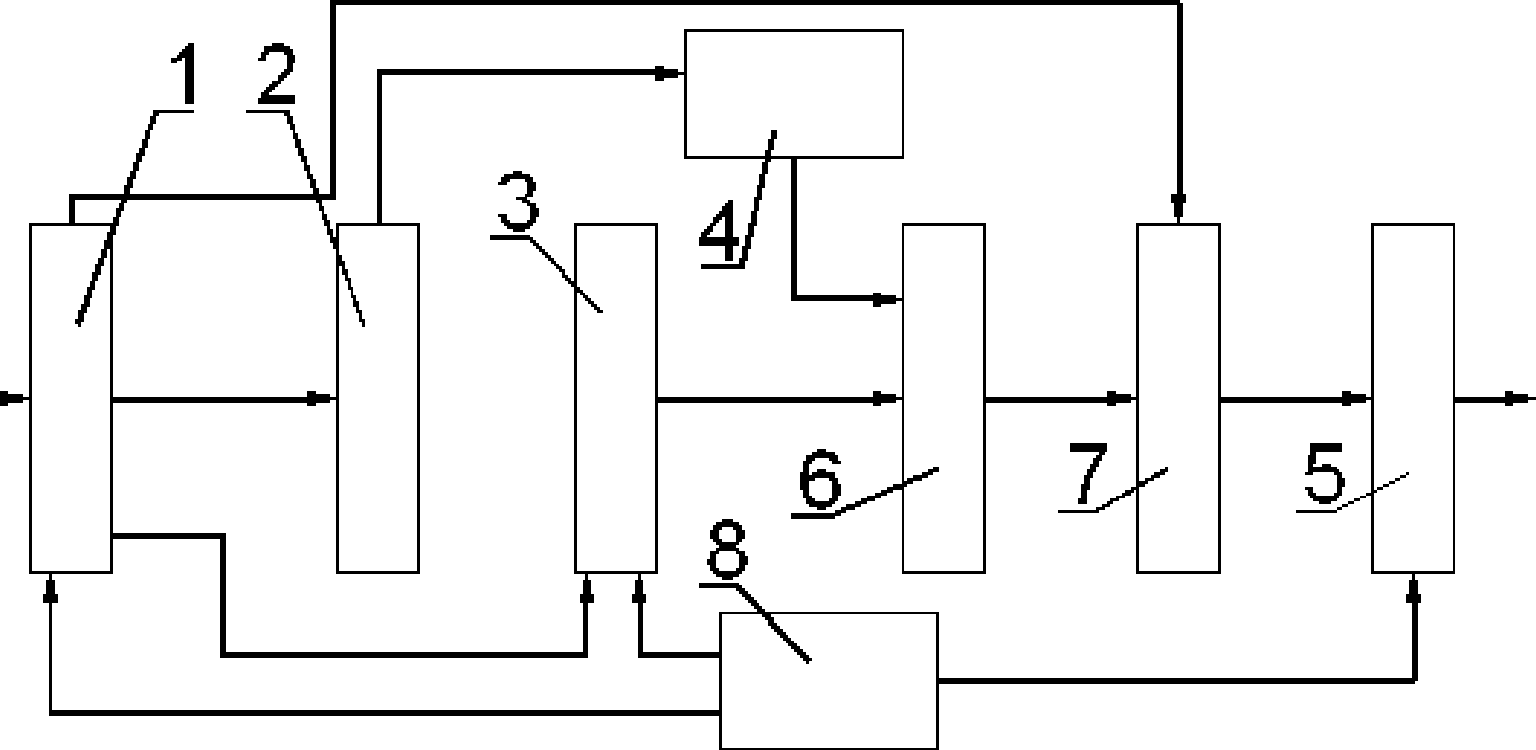

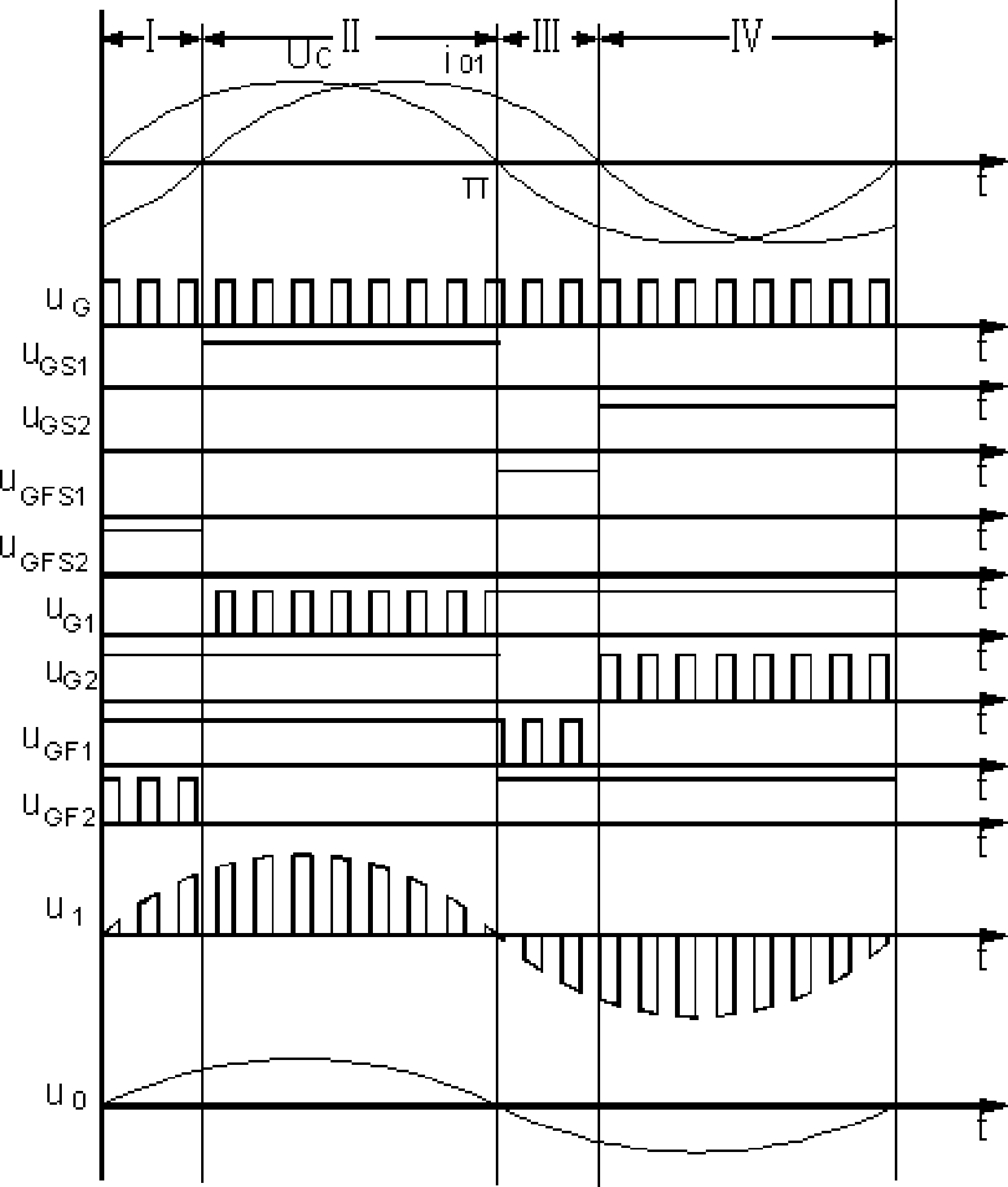

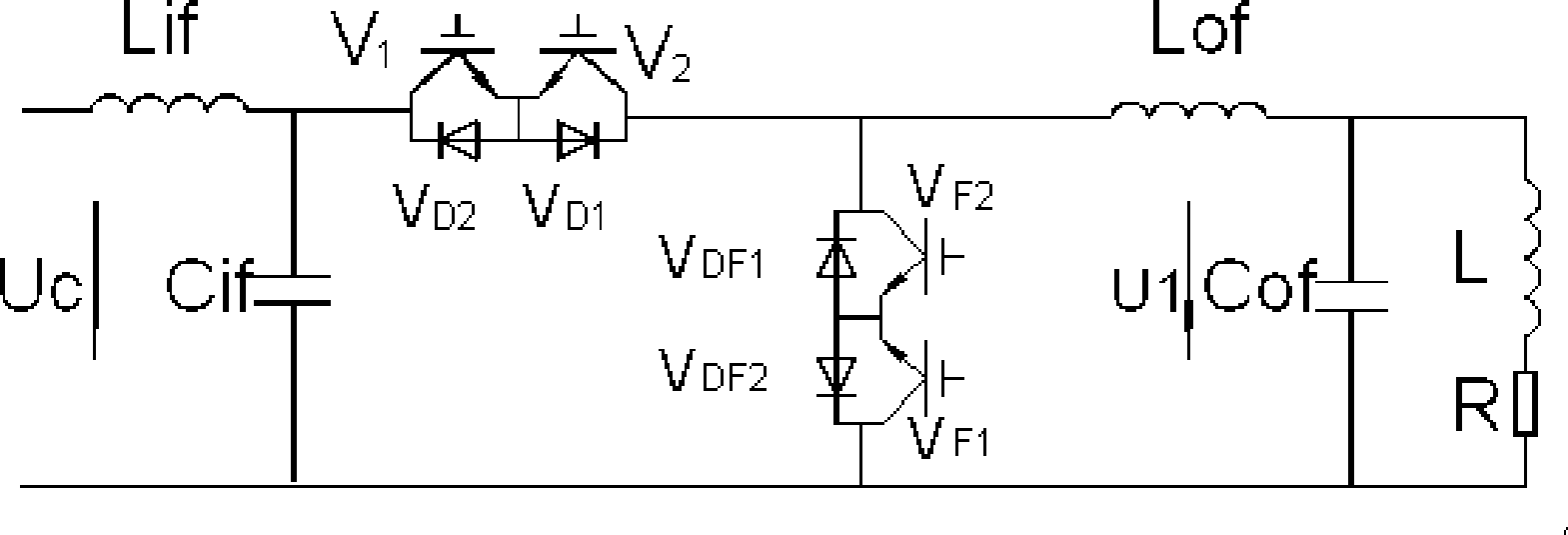

[0015] Embodiments of the present invention: structure includes signal acquisition module 1 and PWM wave signal generation module 3, signal acquisition module 1 can adopt existing analog amplifier, signal converter and pulse shaping circuit, PWM wave signal generation module 3 adopts single-chip microcomputer HT46R23 , the signal acquisition module 1 is connected to the signal combination module 2, and the signal input of the signal combination module 2 is input to the timing interlock module 4, so as to prevent timing overlap between the multi-channel timing control signals, and the output of the PWM wave signal generation module 3 and the timing interlock module 4 The signal is input to the signal modulation module 6 at the same time to obtain the PWM pulse control signal modulated by the timing control signal. Signal co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com