Active vibration damping system and forecast control method thereof

A technology of active vibration reduction and predictive control, applied in vibration suppression adjustment, engine frame, spring/shock absorber, etc., can solve the problems of reaction time and precision control difficulty, achieve low power, reduce overturning moment, heat generation low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A specific embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

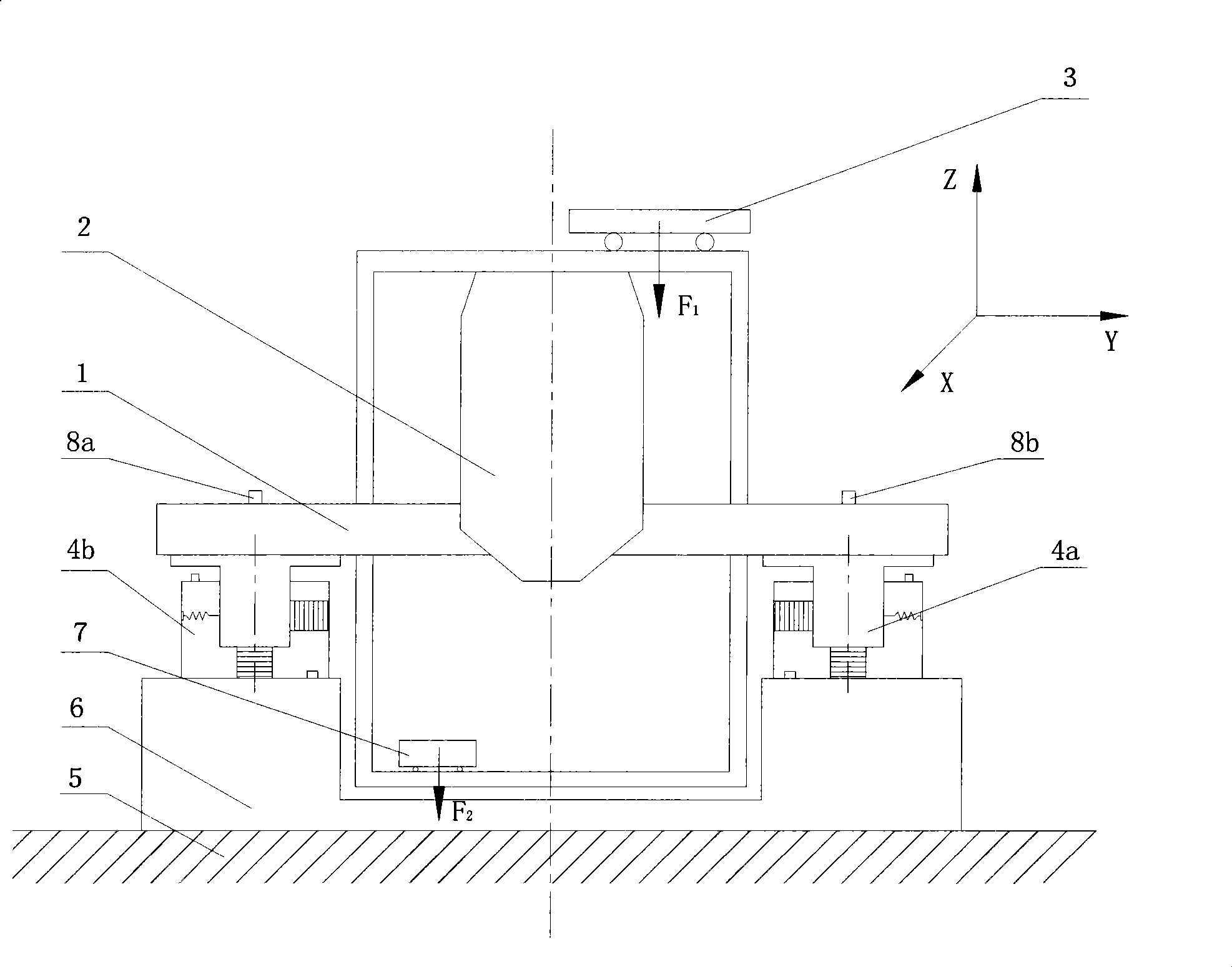

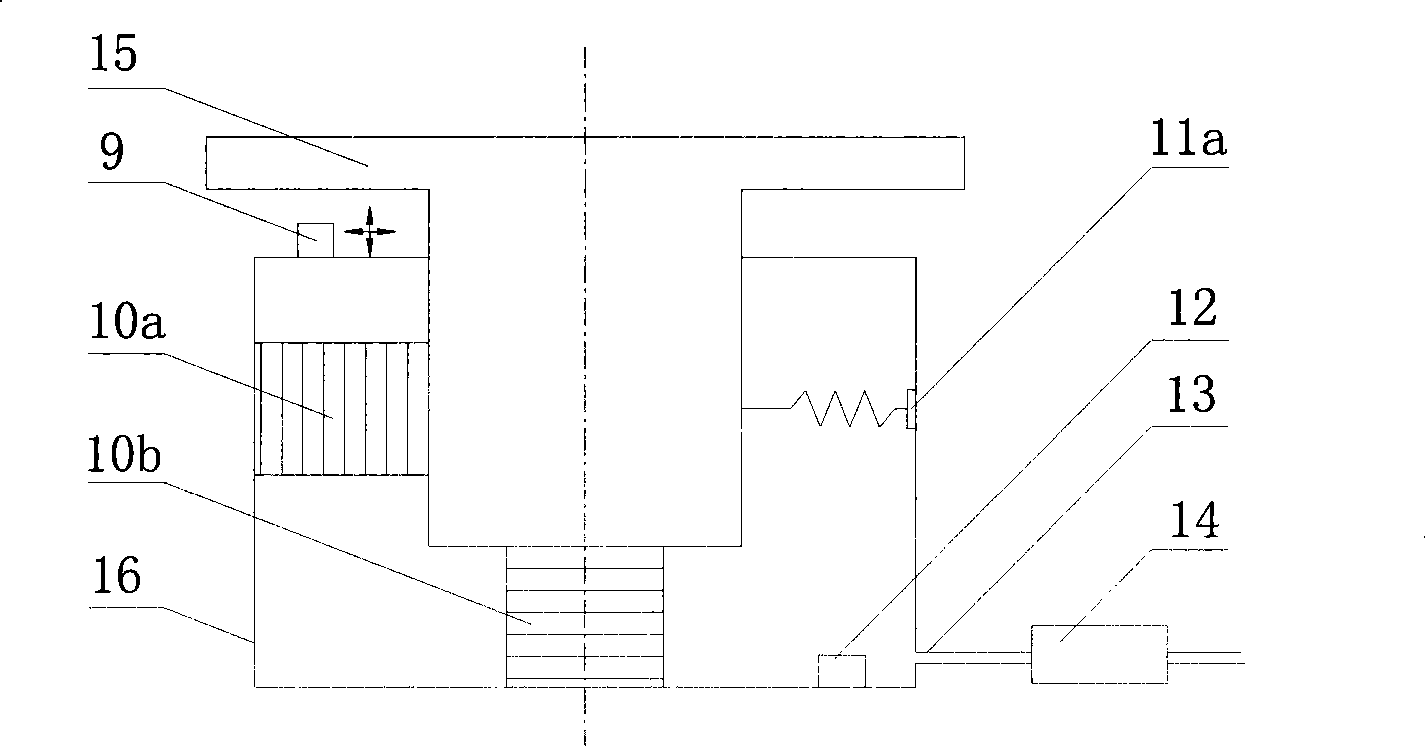

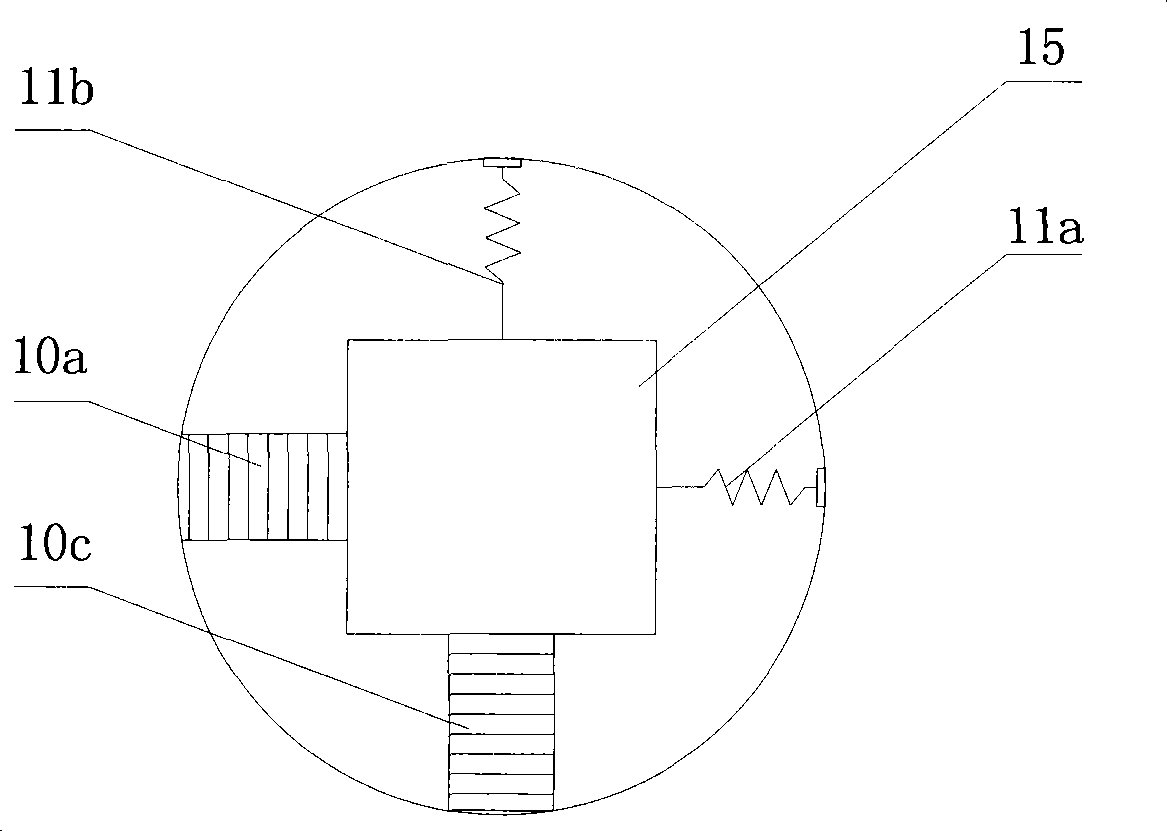

[0031] Such as figure 1 As shown, the schematic diagram of the structural frame of the active vibration reduction system for the step-and-scan lithography machine is described. It mainly includes: main substrate 1, objective lens 2, mask table 3, workpiece table 7, vibration reduction unit 4 (including 4a, 4b, 4c, three vibration reduction units, distributed in an equilateral triangle, see 4c Figure 4 ), base 6. The entire foundation frame is located on the vibration-damping foundation 5, which can effectively isolate the vibration impact generated by the surrounding environment. During the working process of the lithography machine, the mask stage 3 and the workpiece stage 7 are scanned and exposed according to the pre-planned path. Since the mask stage and the silicon wafer stage have a relatively high speed and acceleration, the moving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com