Single-piston type hydraulic free piston engine

A piston engine, single-piston technology, used in power and hydraulic fields, can solve the problems of poor machining processability of piston components, excessive axial dimensions, and uncompact structure of hydraulic free-piston engines. effect on size, improved control and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

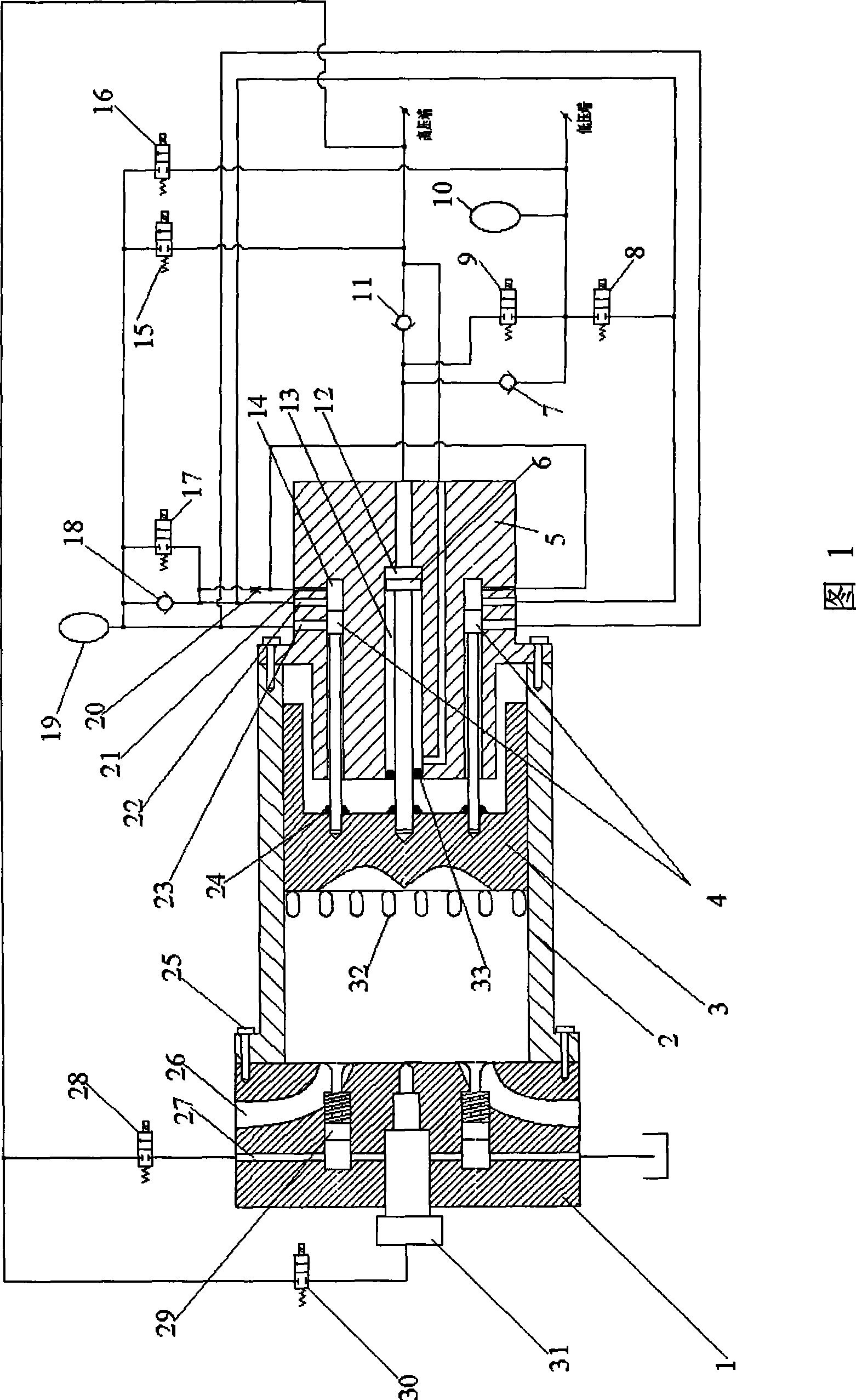

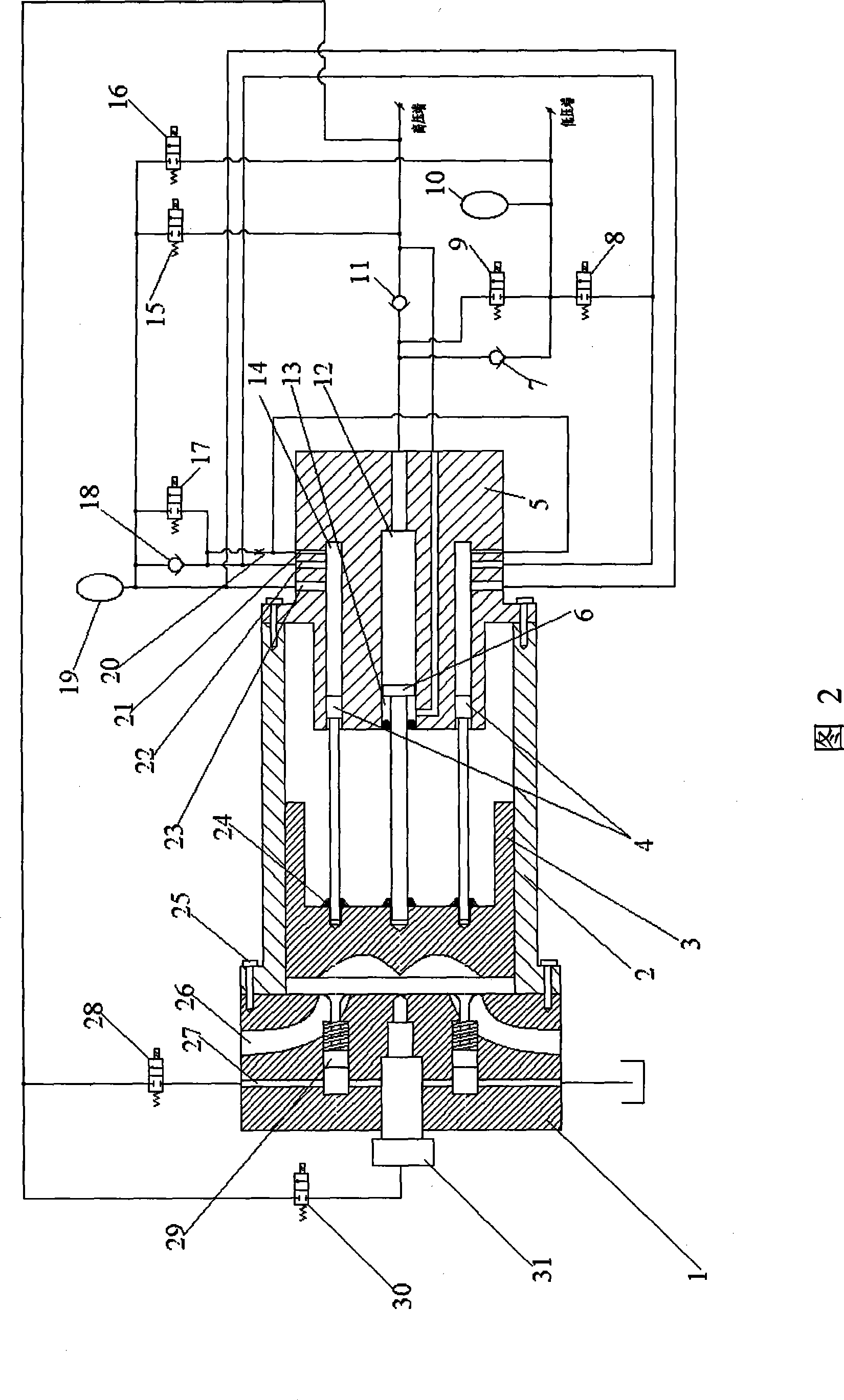

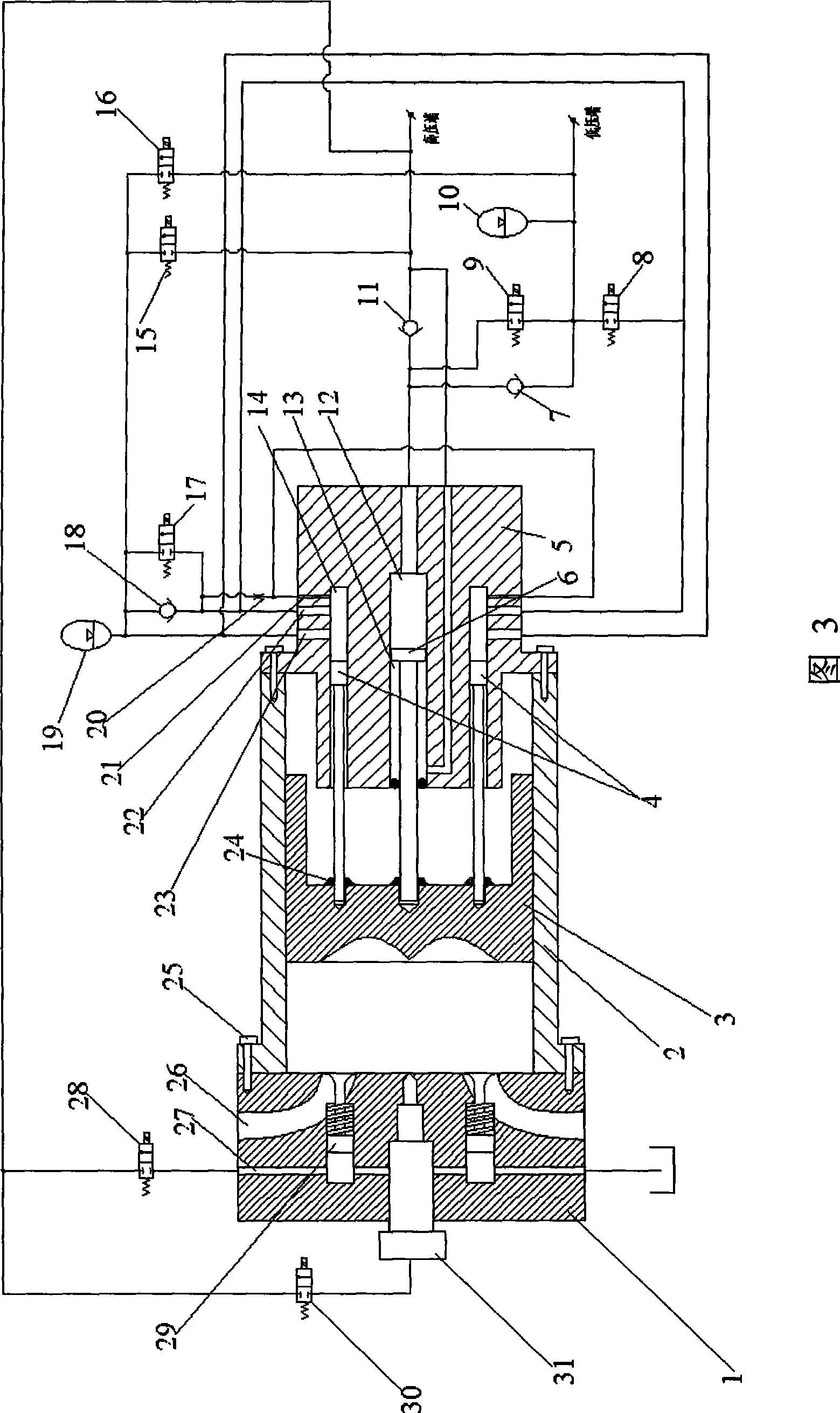

[0027] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0028] The main idea of the technical solution of the present invention integrates the traditional reciprocating piston internal combustion engine and the plunger hydraulic pump, eliminating the need for the internal combustion engine to convert the reciprocating motion of the piston into the rotary motion of the crank linkage mechanism and the rotary motion in the plunger pump. It is converted into a reciprocating swash plate mechanism, and directly connects the piston of the internal combustion engine to the plunger of the hydraulic pump, which not only shortens the transmission chain, but also saves the repeated conversion between different motion forms, and optimizes the engine and transmission. The energy transmission form of the system realizes the flexible adjustment of the power transmissio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com