Circulating mash gas heating technology and apparatus

A technology of circulating gas and gas, which is applied in the field of circulating gas heating technology and devices, can solve the problems of expensive imported equipment, unbalanced, continuous and stable supply of heating gas, etc., and achieve the effects of reducing cost, reducing emissions, and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

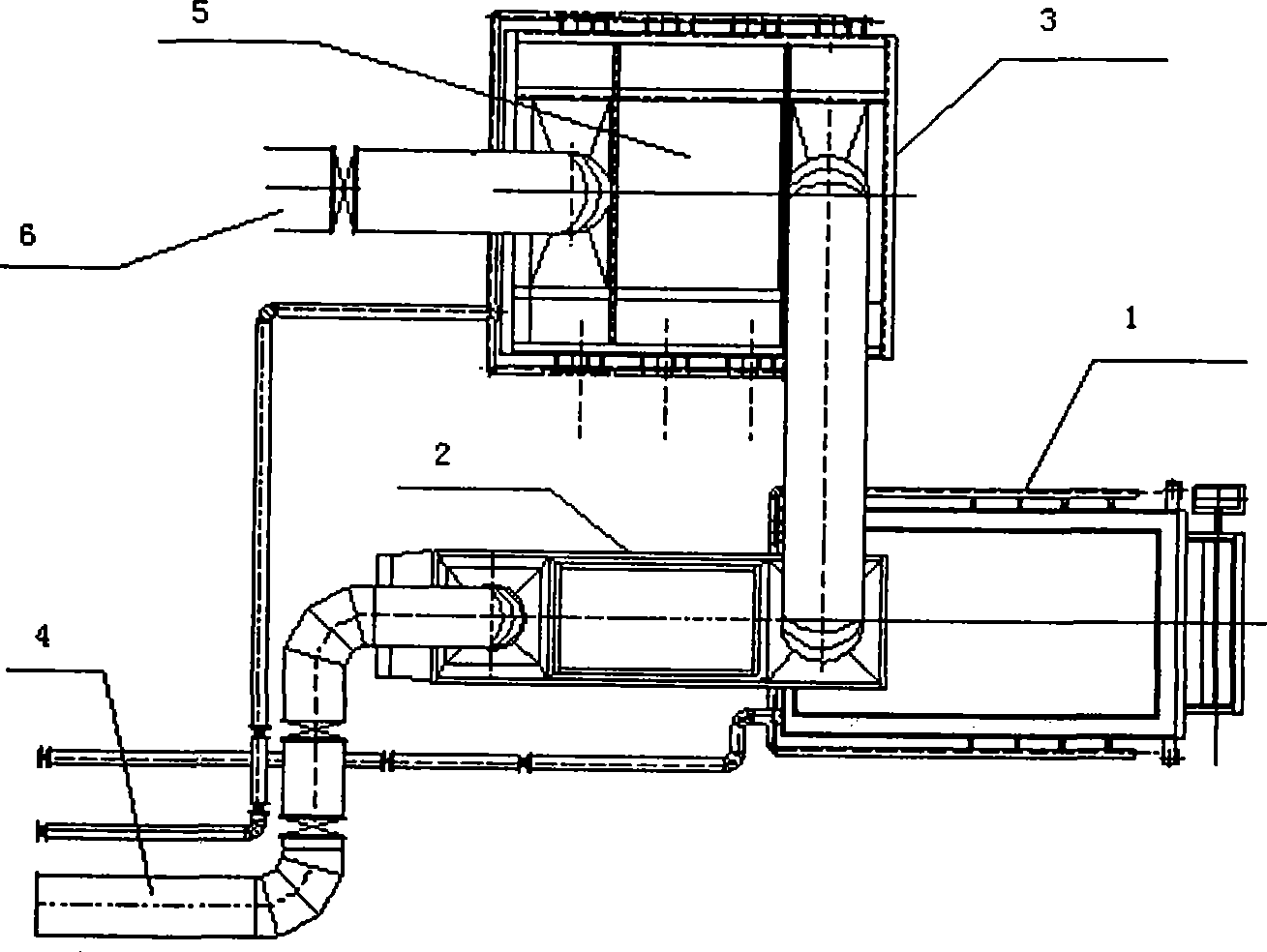

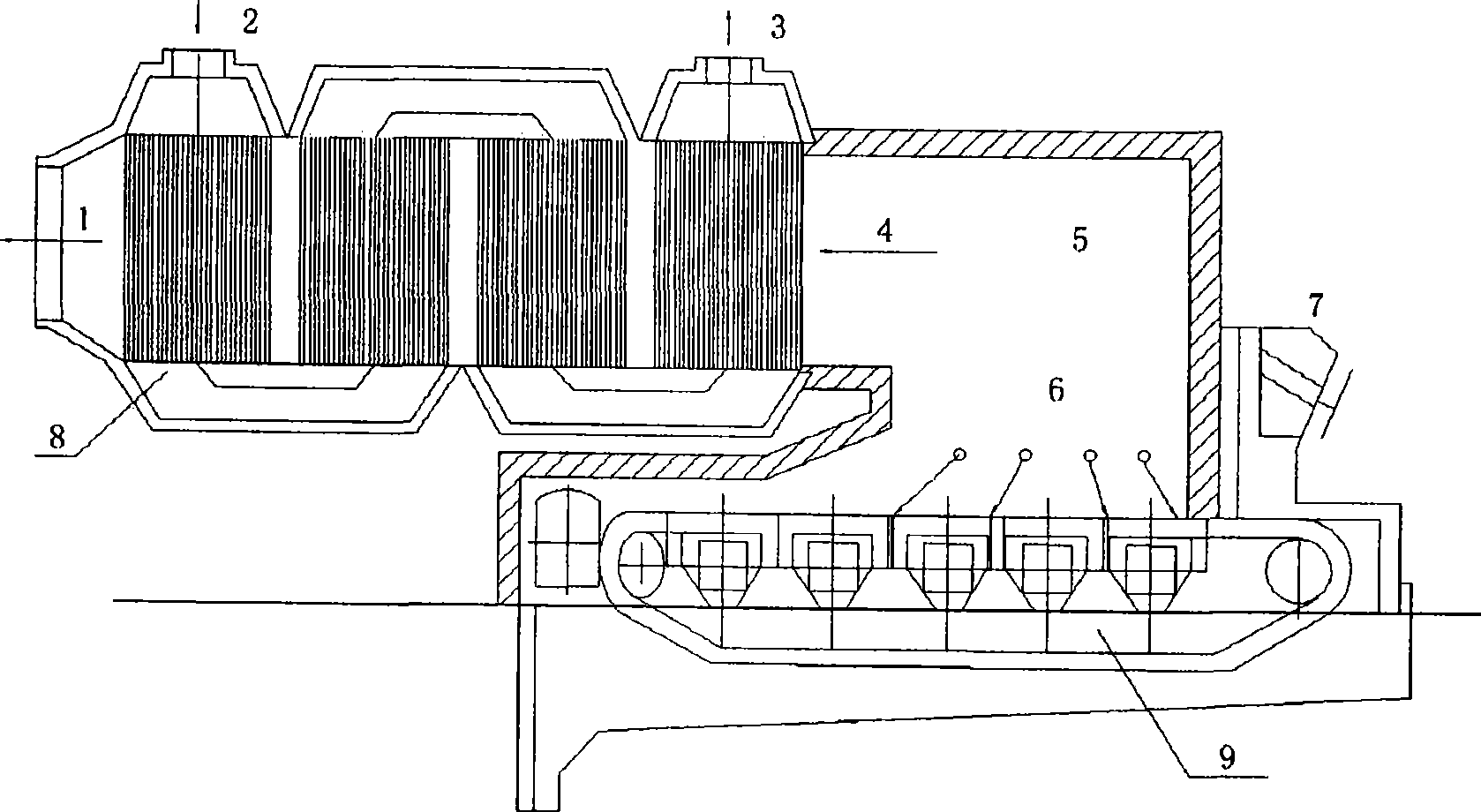

[0011] The specific implementation of the present invention is to ensure continuous, stable and balanced supply of thermal cycle gas at about 700°C. To achieve this purpose, the method of secondary heating is adopted. Although the first stage is a conventional tubular heat exchanger, in order to make full use of the calorific value of the fixed carbon in the semi-coke, and to solve the problem that the gas produced by low-grade oil shale cannot meet the heat demand of the carbonization furnace, semi-coke and Gas co-firing technology. In the second-stage heating furnace, the high-temperature flue gas exchanges heat with the thermal cycle gas that has been heated to 500°C, ensuring that the cycle gas can be heated to 700°C. Since the whole heating process is continuous, stable, balanced, and adjustable, it can meet the requirement of providing thermal cycle gas of about 700°C to the carbonization furnace. Figure 1, Figure 2, and Figure 3 respectively show the device structure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com