Method for preparing alpha-formyloxy phenylacetyl chloride

A formyloxyphenylacetyl chloride technology, applied in the chemical industry, can solve the problems of high toxicity of raw materials, environmental pollution, complex technology, etc., and achieve the effects of convenient mass production, high yield and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

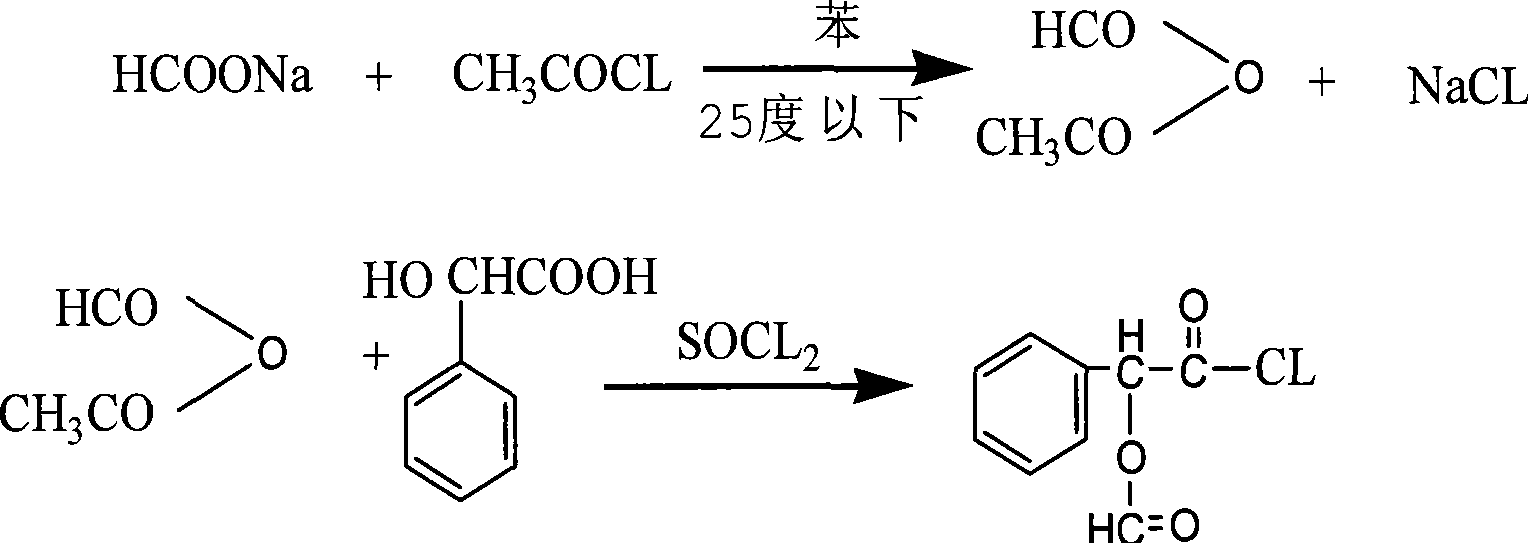

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with specific embodiments.

[0028] The preparation method of a-formyloxyphenylacetyl chloride, the raw materials used in the reaction are: 40 grams of industrial-grade sodium formate, 28 grams of industrial-grade acetyl chloride, 20 grams of protanic acid imported from Japan, and industrial-grade thionyl chloride 22ml, 100ml of industrial grade benzene.

[0029] The preparation process of α-formyloxyphenylacetyl chloride is as follows:

[0030] Step 1 Feeding

[0031] Add 40g of sodium formate and 20ml of benzene into a 500ml four-neck flask, cool down to 20°C with water, then slowly add 28g of acetyl chloride dropwise into the above solution, and control the temperature below 25°C.

[0032] Key points of operation: control the temperature and add slowly.

[0033] Step 2 keep warm

[0034] After the dropwise addition was completed, a thermometer was inserted into the four-necked bottle, and the te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com