Anti strong light and strong heat radiative composite coating and preparation method thereof

A composite coating and thermal radiation technology, which is applied in the coating, metal material coating process, sputtering plating, etc., can solve high temperature, complex problems, etc., and achieve the effects of improving performance, easy access, and increasing transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

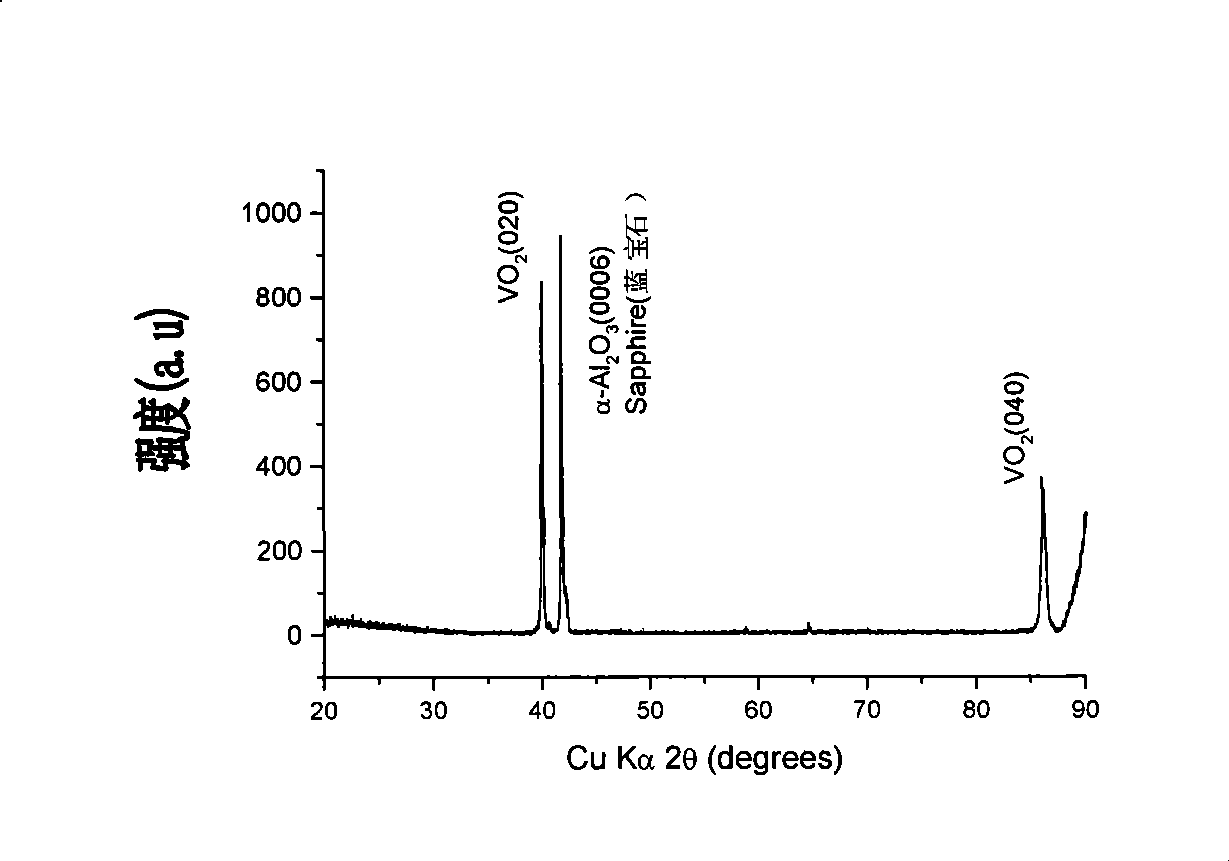

[0031] The preparation method of the vanadium dioxide thin film whose phase transition temperature is 68 DEG C comprises the following steps in sequence:

[0032] (1) The glass substrate is cleaned by ultrasonic waves to remove impurities such as organic pollutants, dust and metal ions on the surface of the substrate, and the vanadium dioxide film is deposited on the glass substrate by radio frequency magnetron sputtering, using a metal vanadium target , the background vacuum is 9×10 -4 pa, the heating temperature is 500-600°C, argon and oxygen are introduced, the total pressure of the sputtering gas is 1Pa, the sputtering power is 100W-150W, the sputtering time is 30-120 minutes, and the film thickness is about 100-200nm. The above-mentioned vanadium dioxide film can also be prepared by other methods, such as pulsed laser deposition and sol-gel method.

[0033] (2) Deposit a layer of nickel phthalocyanine thin film on the above-mentioned W-doped vanadium dioxide thin film by...

Embodiment 2

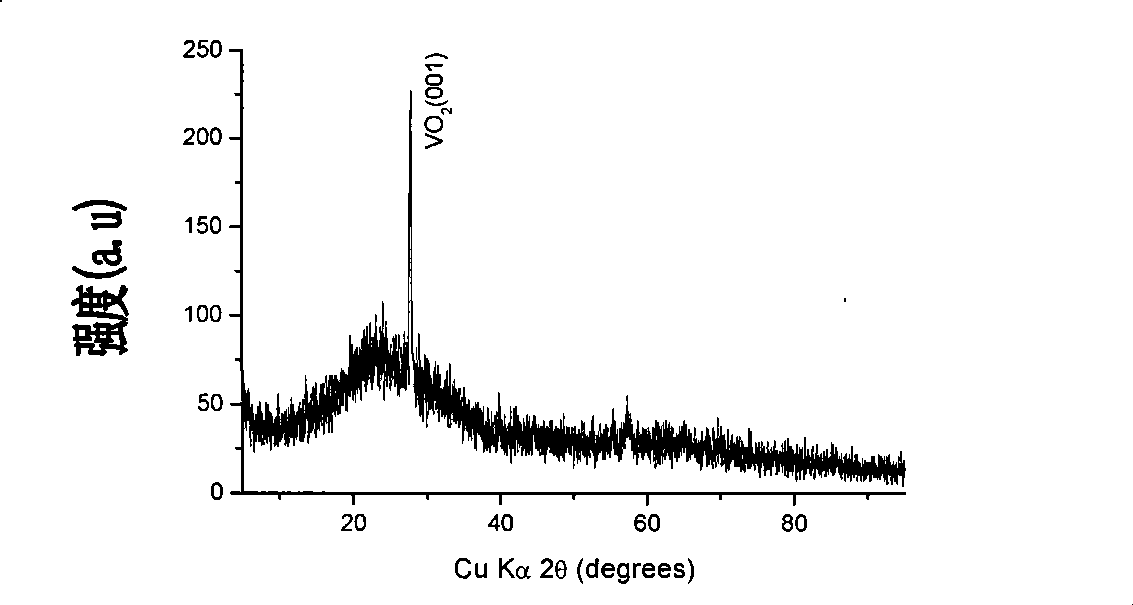

[0036] The preparation method of the vanadium dioxide thin film whose phase transition temperature is 35 DEG C comprises the following steps in sequence:

[0037] (1) The glass substrate is cleaned by ultrasonic waves to remove impurities such as organic pollutants, dust and metal ions on the surface of the substrate, and the vanadium dioxide film is deposited on the glass substrate by radio frequency magnetron sputtering, using a metal vanadium target , place the tungsten wire symmetrically on the vanadium target, sputter the vanadium target and the tungsten wire at the same time, the background vacuum is 9×10 -4 Pa, the heating temperature is 500-600°C, the argon and oxygen are fed, the total sputtering gas pressure is 1Pa, the sputtering power is 120W, the sputtering time is 30-120 minutes, and the film thickness is about 100-200nm.

[0038] (2) Deposit a layer of nickel phthalocyanine thin film on the above-mentioned W-doped vanadium dioxide thin film by spin coating metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Phase transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com