Polyester film for shrinkable cigarette pack

A technology for polyester film and packaging, applied in the field of polyester film, can solve the problems of unclear cigarette label pattern, dull color, gas barrier performance (fragrance retention, surface glossiness is not ideal, etc.)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

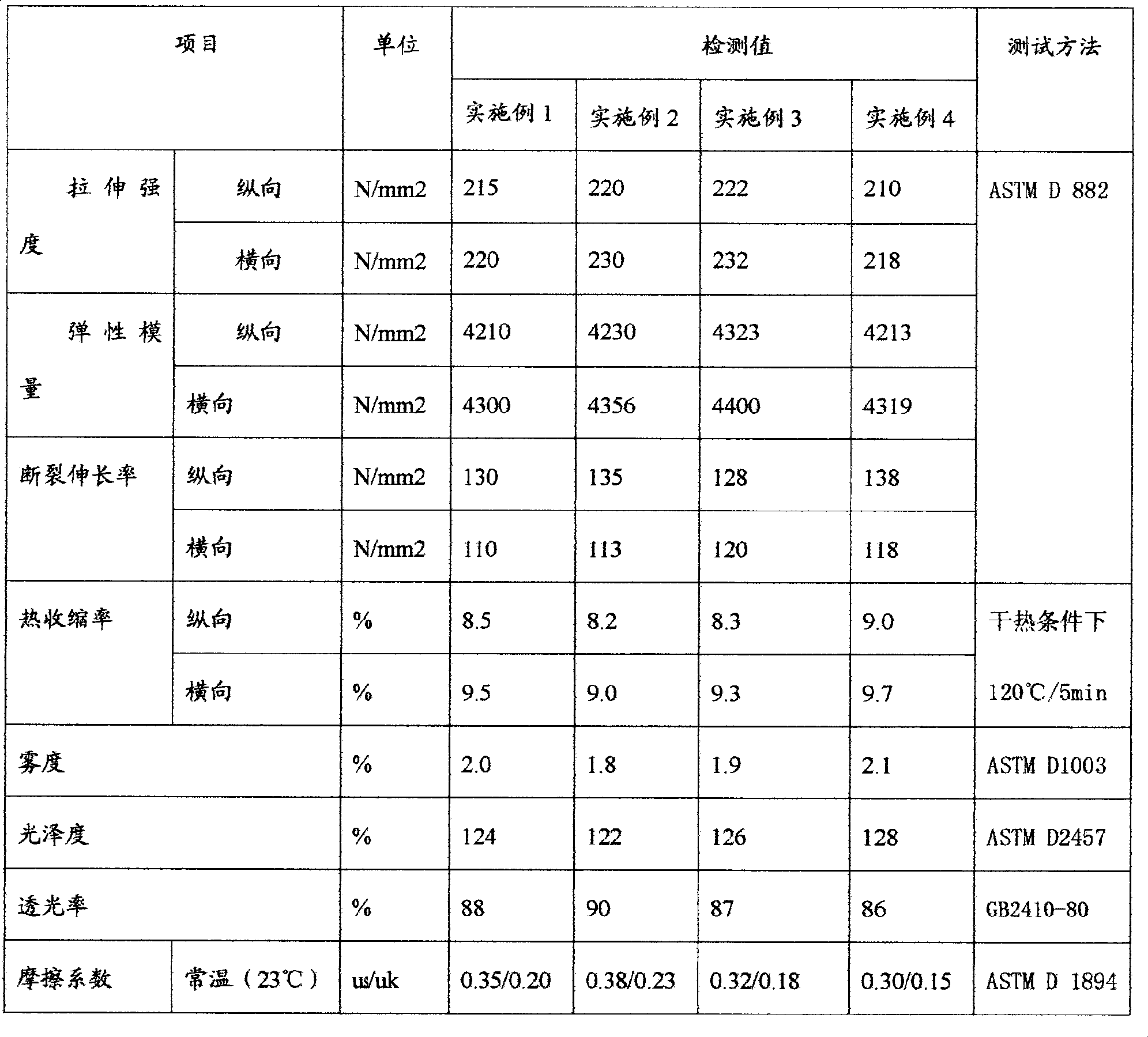

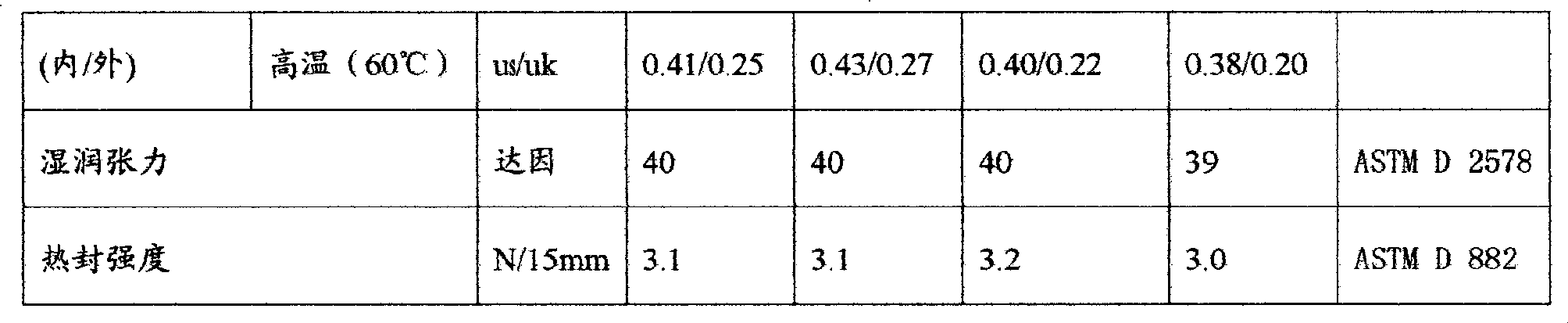

Examples

Embodiment 1

[0019] Raw material formula:

[0020] 1) Upper surface layer

[0021] 94 parts by weight of PETG,

[0022] 6 parts by weight of silicone slip agent masterbatch, wherein

[0023] The carrier of the silicone slip agent masterbatch is PETG, and the effective ingredients are silicone resin particles and silicon dioxide particles, and the concentration is 26wt%.

[0024] 2) core layer

[0025] 91 parts by weight of PET chips,

[0026] PETG 8 parts by weight,

[0027] 1 part by weight of antistatic agent masterbatch, wherein

[0028] The antistatic agent masterbatch contains nonionic antistatic agent polyethylene glycol ester and cationic antistatic agent diethanol dodecylamine quaternary ammonium salt compound, with polyethylene terephthalate (PET) as the carrier, The concentration is 20wt%, and the weight ratio of the polyethylene glycol ester and the quaternary ammonium salt compound of diethanol dodecylamine is 1:4.

[0029] 3) Lower surface layer

[0030] 99 parts by we...

Embodiment 2

[0041] Raw material formula:

[0042] 1) Upper surface layer

[0043] 95 parts by weight of PETG,

[0044] 5 parts by weight of silicone slip agent masterbatch, wherein

[0045] The carrier of the silicone slip agent masterbatch is PETG, and the effective ingredients are silicone resin particles and silicon dioxide particles, and the concentration is 26wt%.

[0046] 2) core layer

[0047] 94 parts by weight of PET chips,

[0048] 5 parts by weight of PETG,

[0049] 1 part by weight of antistatic agent masterbatch, wherein

[0050] The antistatic agent masterbatch contains nonionic antistatic agent polyethylene glycol ester and cationic antistatic agent diethanol dodecylamine quaternary ammonium salt compound, with polyethylene terephthalate (PET) as the carrier, The concentration is 20wt%, and the weight ratio of the polyethylene glycol ester and the quaternary ammonium salt compound of diethanol dodecylamine is 1:3.

[0051] 3) Lower surface layer

[0052] 99 parts by...

Embodiment 3

[0057] Raw material formula:

[0058] 1) Upper surface layer

[0059] 93 parts by weight of PETG,

[0060] 7 parts by weight of silicone slip agent masterbatch, wherein

[0061] The carrier of the silicone slip agent masterbatch is PETG, and the effective ingredients are silicone resin particles and silicon dioxide particles, and the concentration is 26wt%.

[0062] 2) core layer

[0063] 92 parts by weight of PET chips,

[0064] PETG 6 parts by weight,

[0065] 2 parts by weight of antistatic agent masterbatch, wherein

[0066] The antistatic agent masterbatch contains nonionic antistatic agent polyethylene glycol ester and cationic antistatic agent diethanol dodecylamine quaternary ammonium salt compound, with polyethylene terephthalate (PET) as the carrier, Concentration is 20wt%, the weight ratio of the quaternary ammonium salt compound of polyethylene glycol ester and diethanol dodecylamine is 1:3.5. 3) lower surface layer

[0067] 98 parts by weight of PETG,

[006...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com