Implementation of jog-opening, adaptive ability and automatic anti-blocking and rotating function of drill

A technology for drilling rigs and racks, which is applied to the automatic control system of drilling, drilling equipment, earth-moving drilling, etc., can solve the problems of sudden sticking, large torque, rotation speed and propulsion force, and scrapped drilling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

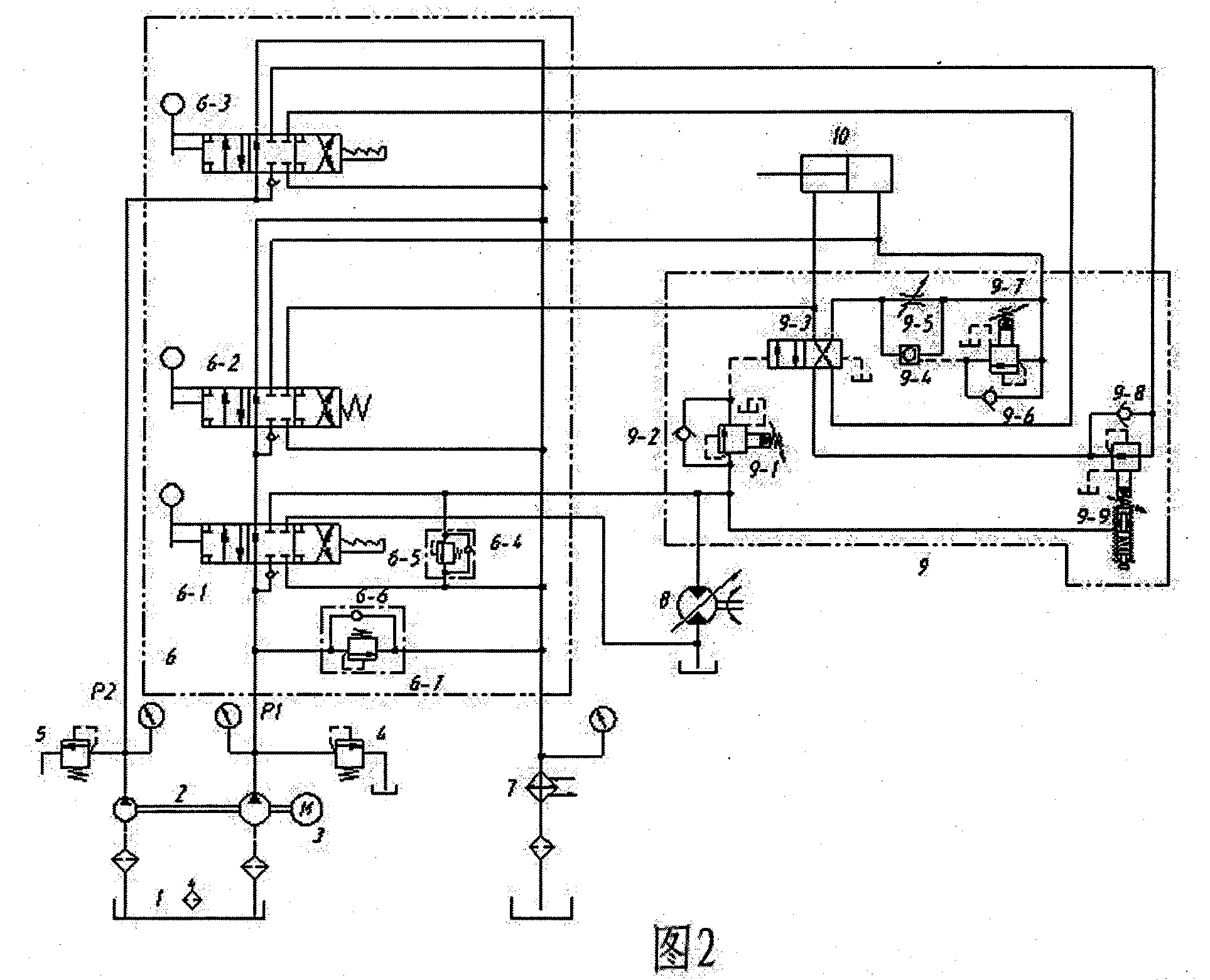

[0011] When the drilling rig starts drilling, such as figure 2 In the hydraulic system shown, the hydraulic control reversing valve 9-3 is working in the right position. Due to the small drilling resistance, the oil pressure in the piston chamber of the thrust cylinder 10 is low, the overflow valve 9-7 is closed, and the hydraulic control check valve 9- 4 close; the pressure oil P2 enters the piston chamber of the propulsion cylinder 10 through the reversing valve 6-3, the remote control decompression valve 9-9, the hydraulic control reversing valve 9-3, and the throttle valve 9-5. The throttling effect of 9-5, the pressure oil flow into the piston chamber of the propulsion cylinder 10 is small and the pressure is low, so that the piston rod of the propulsion cylinder advances slowly and the propulsion force is small, realizing the function of lightly pushing the drilling rig to open the hole and ensuring the accurate position of the hole .

[0012] When the rig works normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com