Method for preparing high specific surface diamond electrode

A diamond electrode, high specific surface technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of poor catalytic oxidation ability of organic matter, loss of electrocatalytic performance, reduction of oxidation current efficiency, etc., to achieve short preparation time, Prepare fast, easy-to-handle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The preparation method of high specific surface diamond electrode, it comprises the steps:

[0038] 1) Cleaning of metal electrodes:

[0039] Soak the metal tungsten electrode surface with dilute NaOH solution (mass concentration is 10%) for 2 minutes to remove the oil stain on the metal tungsten electrode surface; rinse it with clean water after taking it out, and then put the metal tungsten electrode in dilute HCl solution (mass Concentration is 5%), soaked in 2 minutes, to remove the oxide on the metal tungsten electrode surface;

[0040] 2) Preparation of conductive diamond film:

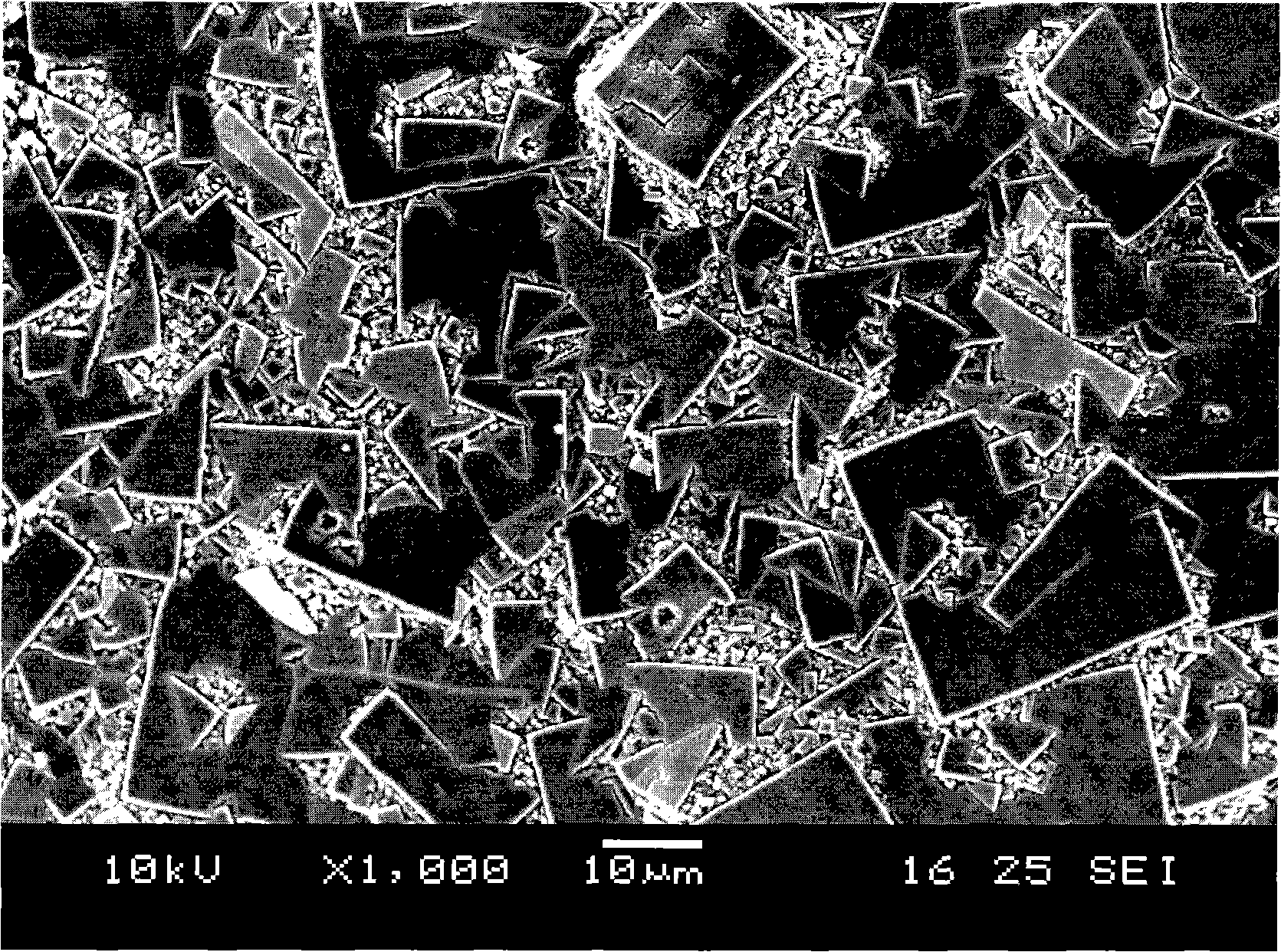

[0041] Deposit a conductive diamond film on the surface of the metal electrode by chemical vapor deposition on the metal electrode after step 1) cleaning (degreasing and rust removal), and the thickness is controlled at 160 microns;

[0042] The metal tungsten electrode is supported by alumina so that the diamond film can be deposited on both the front and back sides;

[0043] The spec...

Embodiment 2

[0053] The preparation method of high specific surface diamond electrode, it comprises the steps:

[0054] 1) Cleaning of metal electrodes:

[0055] Soak the metal molybdenum electrode surface with dilute potassium hydroxide solution (mass concentration is 20%) for 1 minute to remove the oil stain on the metal electrode surface; rinse it with clear water after taking it out, then place the metal molybdenum electrode in dilute hydrochloric acid solution ( Mass concentration is 20%), soaked in 1 minute, to remove the oxide of metal molybdenum electrode surface;

[0056] 2) Preparation of conductive diamond film:

[0057] The metal molybdenum electrode after step 1) cleaning (removing oil and rust) utilizes the known chemical vapor deposition method to deposit a layer of conductive diamond film on the surface of the metal electrode, and the thickness is controlled at 10 microns;

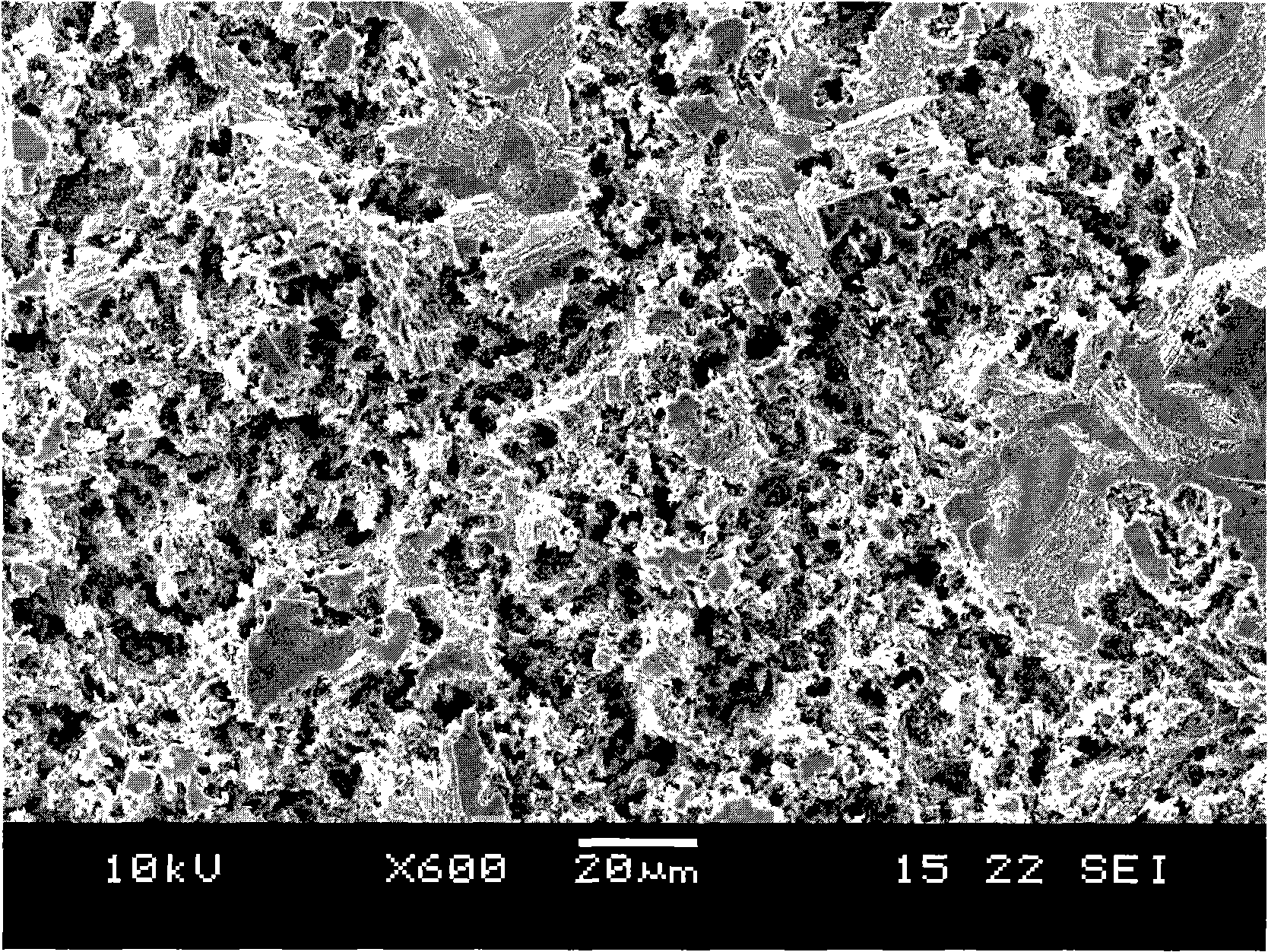

[0058] 3) Prepare a solid etching material on the surface of the conductive diamond film:

[0059...

Embodiment 3

[0065] The preparation method of high specific surface diamond electrode, it comprises the steps:

[0066] 1) Cleaning of metal electrodes:

[0067] Soak the metal titanium electrode surface with a mixed solution of dilute sodium hydroxide and potassium hydroxide (mass concentration is 5%) for 5 minutes to remove the oil stain on the metal titanium electrode surface; rinse it with clear water after taking it out, and then put the metal titanium electrode Be placed in dilute hydrochloric acid solution (mass concentration is 5%) and soak for 5 minutes, to remove oxides on the surface of metal titanium electrodes;

[0068] 2) Preparation of conductive diamond film:

[0069] Deposit a layer of conductive diamond film on the surface of the metal electrode using the known chemical vapor deposition method on the metal titanium electrode after step 1) cleaning (degreasing and rust removal), and the thickness is controlled at 300 microns;

[0070] 3) Prepare a solid etching material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com