Control method of steel-tube online normalization

A control method and technology for steel pipes, applied in the direction of rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as unstable speed and affecting the normalization effect of steel pipes, achieve uniform temperature, ensure fast-paced production, and ensure stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention can be further illustrated by the following examples:

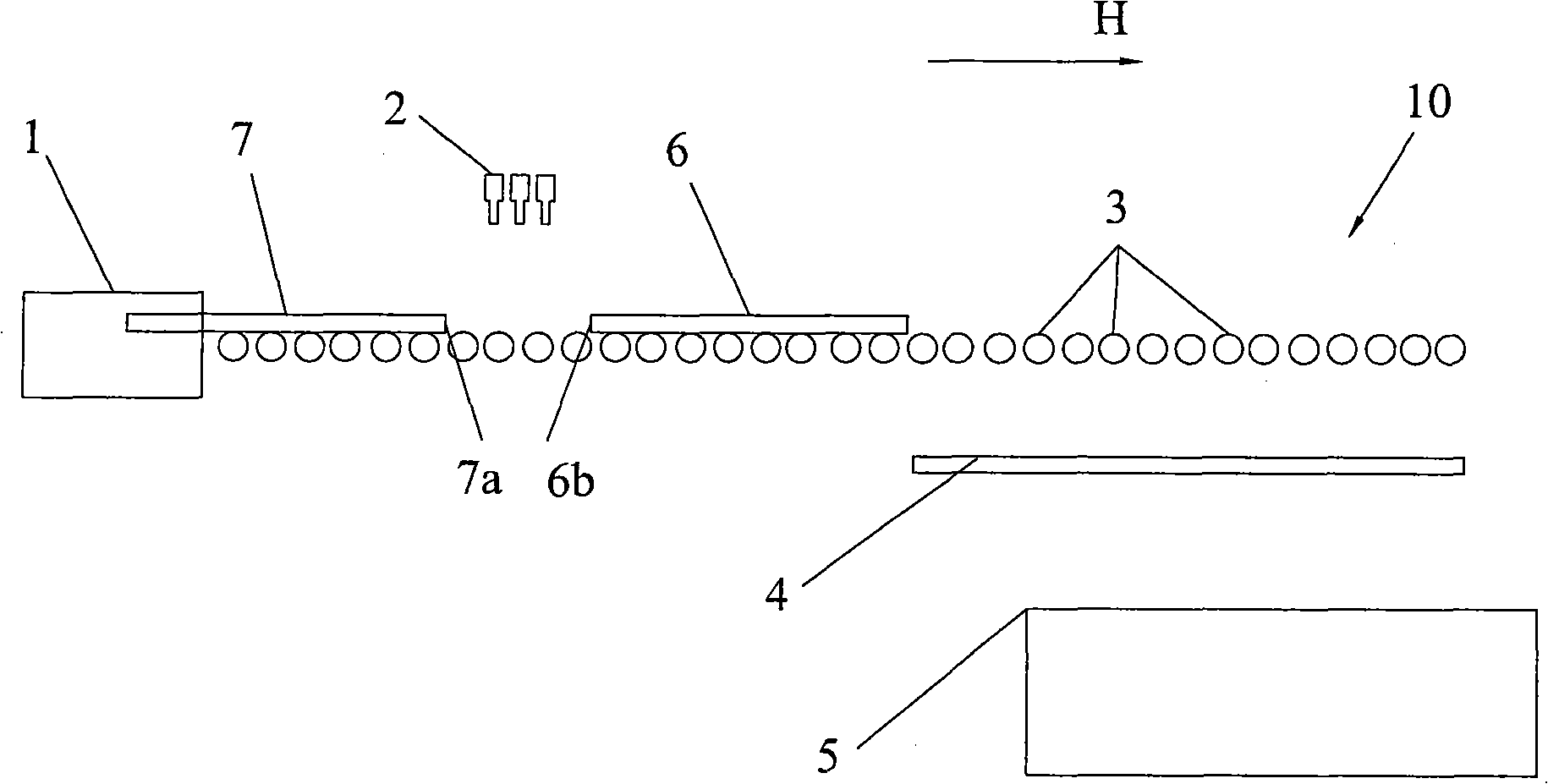

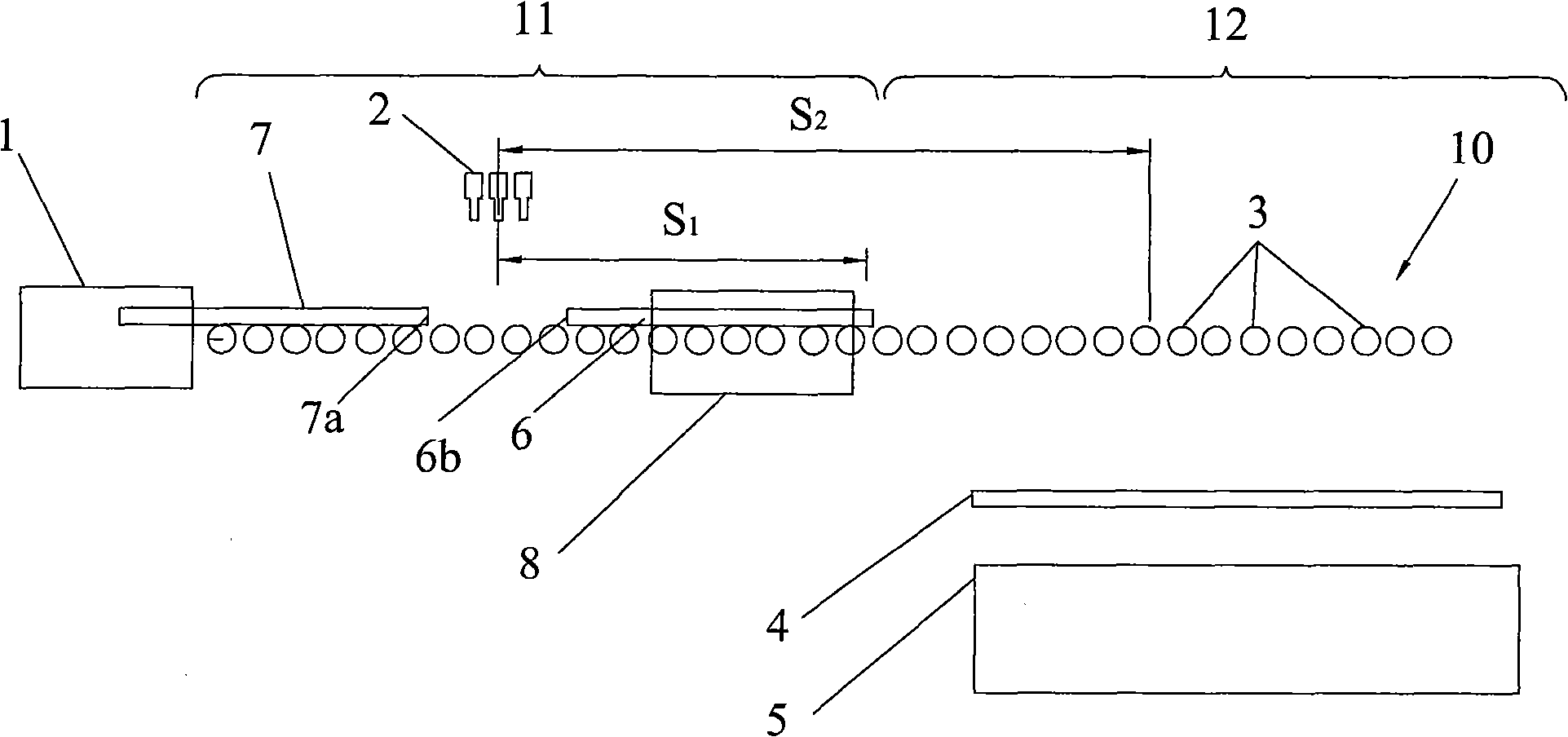

[0034] Such as image 3As shown, in the steel pipe normalization production process, the steel pipe production line includes a stretching and reducing machine 1, a conveying roller table 10, an infrared detector 2, a normalization equipment 8, a speed regulating device, and a material throwing device (only the material throwing device is shown in the figure). Plate 4 part), cooling bed 5 and controller (not shown in the figure). Wherein the controller is preferably a PLC controller. After the steel pipe 6 is rolled by the rolling machine of the stretching and reducing machine 1, it is transported to the conveying roller table 10, and the steel pipe 6 is thrown once and twice through the throwing plate 4, and finally the steel pipe 6 is placed on the cooling bed 5 superior. In order to realize the online normalization of steel pipes, the normalization equipment 8 is arranged on the conveying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com