Preparation method of functional microsphere with light/temperature/magnetism multiple response

A technology of responsiveness and microspheres, applied in the field of preparation of functional microspheres, which can solve the problems of less reports on triple responsive functional microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

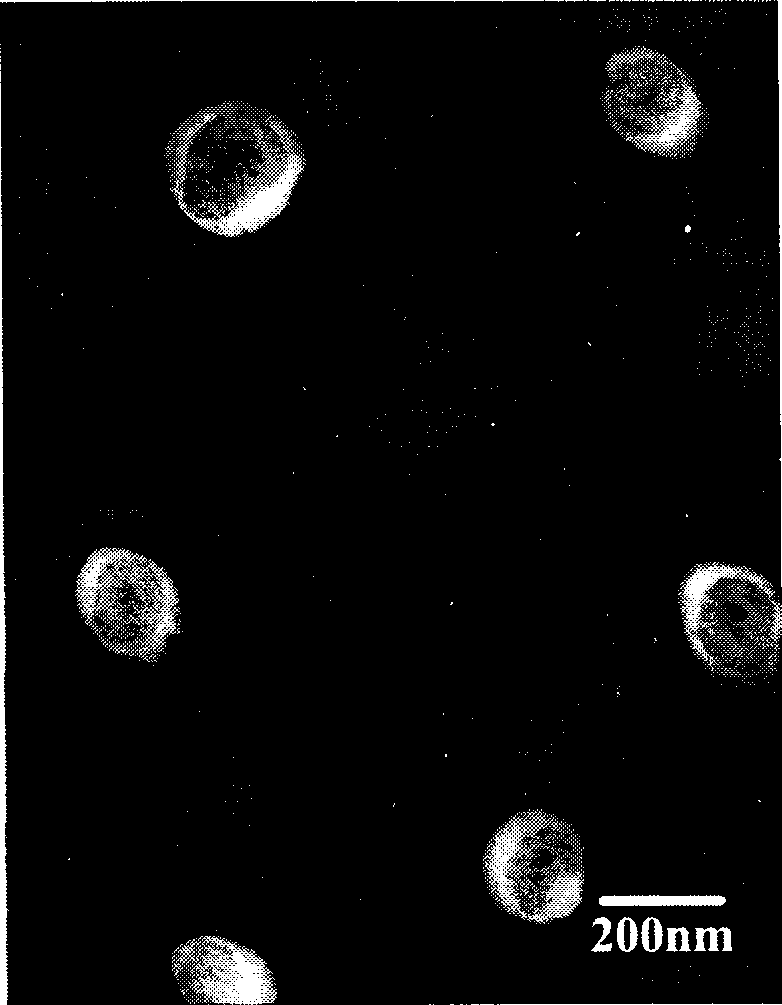

Image

Examples

Embodiment 1

[0011] Example 1: In a 100mL three-necked bottle, 50mL of an aqueous solution of 100mg of magnetic silica microspheres modified with a double bond was added, 160mg of N-isopropylacrylamide (NIPAM), 160mg of NIPAM, aminoethyl methacrylate ( AEMA) 40mg and N, N'-methylenebisacrylamide monomer (MBA) 2.0mg, in N 2 Under the conditions, the temperature was raised to 65-75°C, and after 0-1 hour of stabilization, 10 mg of initiator potassium persulfate was added, and the reaction was completed after 4-6 hours. The resulting product was washed with water by repeated centrifugation to remove unreacted monomers, and then freeze-dried to remove water.

[0012] The lyophilized product was redispersed into 40 mL of N, N-dimethylformamide (DMF) solvent under high-speed stirring, and then 72.7 mg of catalyst triethylamine and 64.8 mg of photosensitive molecule 2-diazo were dissolved. - 5 mL of DMF solution of 1-naphthoquinone-5-sulfonyl chloride, after 3-5 hours of reaction in the dark, the...

Embodiment 2

[0013] Example 2: In a 100mL three-necked bottle, 50mL of an aqueous solution of 100mg of magnetic silica microspheres modified with a double bond was added, 520mg of N-isopropylacrylamide (NIPAM), methacrylate aminoethyl ( AEMA) 40mg and N, N'-methylenebisacrylamide monomer (MBA) 5.6mg, in N 2 Under the conditions, the temperature was raised to 65-75°C, and after 0-1 hour of stabilization, 28 mg of initiator potassium persulfate was added, and the reaction was completed after 4-6 hours. The resulting product was washed with water by repeated centrifugation to remove unreacted monomers, and then freeze-dried to remove water.

[0014] The lyophilized product was re-dispersed in 40 mL of N, N-dimethylformamide (DMF) solvent under high-speed stirring, and then 87.3 mg of catalyst triethylamine and 194.5 mg of photosensitive molecule 2-diazo were dissolved. - 5 mL of DMF solution of 1-naphthoquinone-5-sulfonyl chloride, after 3-5 hours of reaction in the dark, the obtained produc...

Embodiment 3

[0015] Example 3: In a 100mL three-necked bottle, 50mL of an aqueous solution of 100mg of magnetic silica microspheres modified with a double bond was added, and 720mg of N-isopropylacrylamide (NIPAM) and aminoethyl methacrylate ( AEMA) 40mg and N, N'-methylenebisacrylamide monomer (MBA) 7.6mg, in N 2 Under the conditions, the temperature was raised to 65-75°C, and after being stable for 0-1 hour, 45.6 mg of initiator potassium persulfate was added, and the reaction was completed after 4-6 hours. The resulting product was washed with water by repeated centrifugation to remove unreacted monomers, and then freeze-dried to remove water.

[0016] The lyophilized product was redispersed into 40 mL of N,N-dimethylformamide (DMF) solvent under high-speed stirring, and then 14.5 mg of catalyst triethylamine and 13.0 mg of photosensitive molecule 2-diazo were added. - 5 mL of DMF solution of 1-naphthoquinone-5-sulfonyl chloride, after 3-5 hours of reaction in the dark, the obtained pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com