Alkaline cell anode mixture granulation screen apparatus

A positive electrode mixture and alkaline battery technology, which is applied in the field of positive electrode mixture granulation and screening devices for alkaline batteries, can solve the problems of increased carbonation degree of positive electrode materials, adverse effects of stable molding process, inability to separate in time, etc., and achieves stable preparation and Follow-up molding process, improving effect and yield, and improving the effect of one-time yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

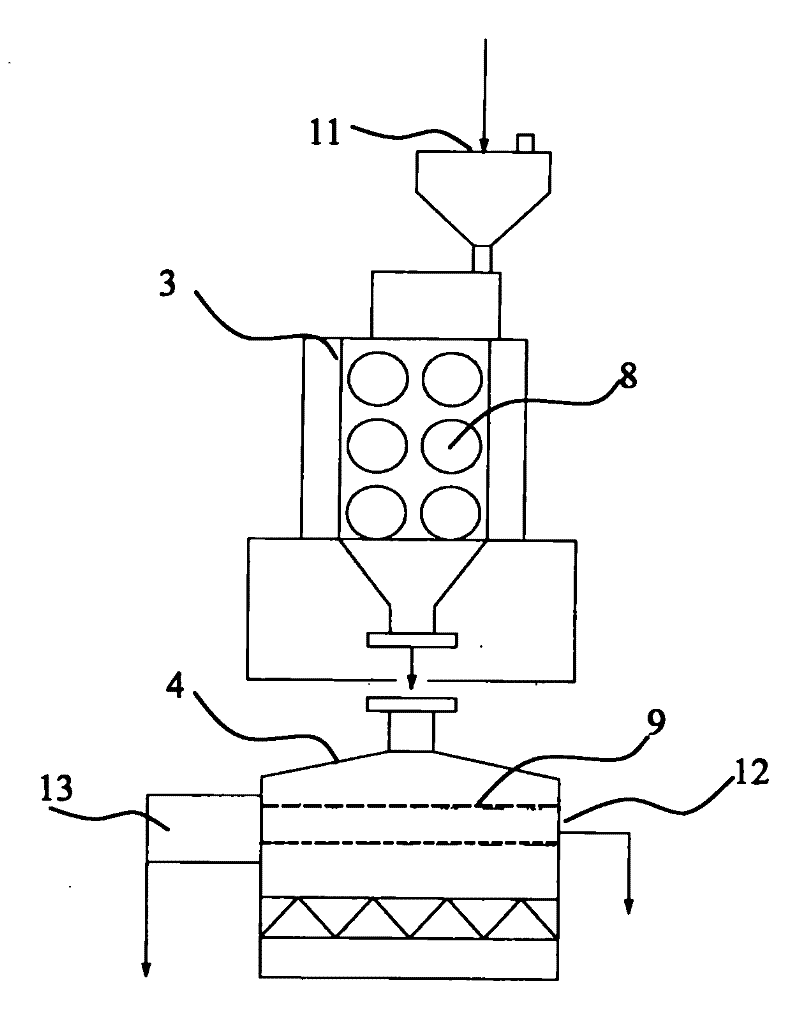

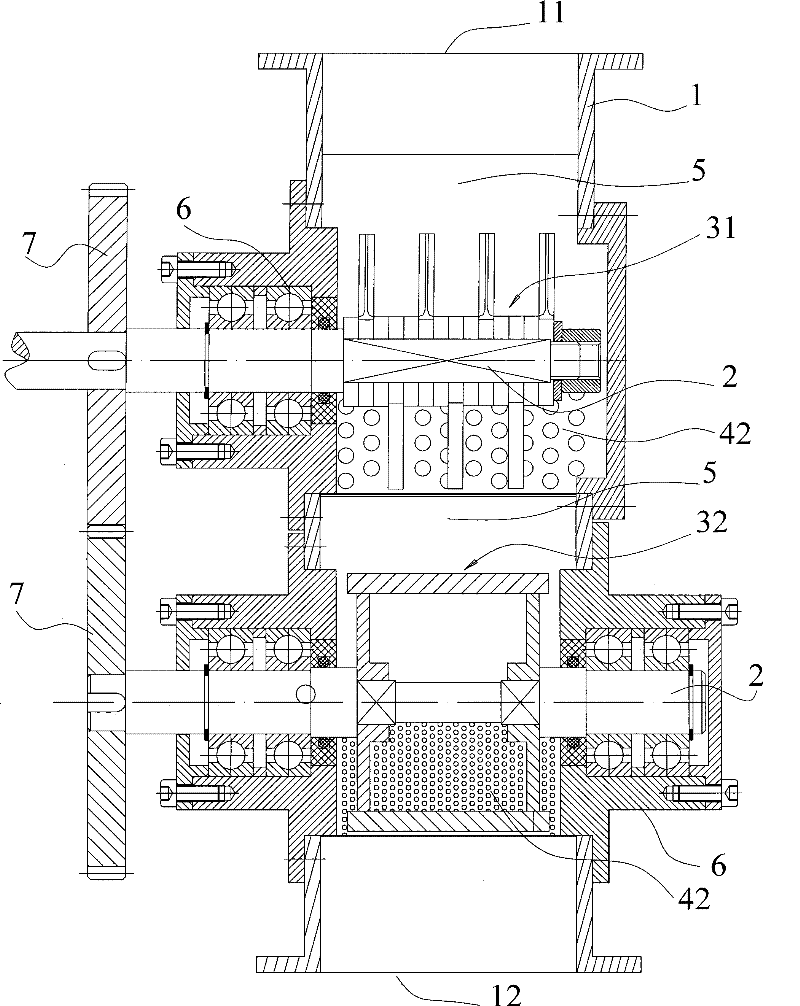

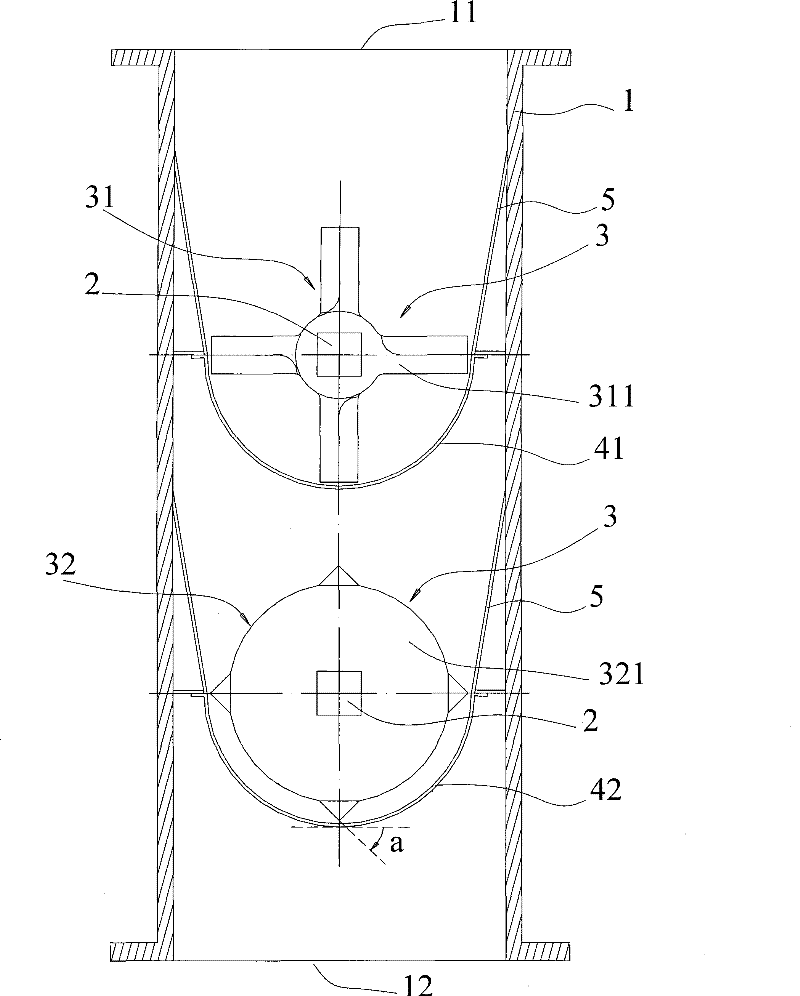

[0051] Example: such as figure 2 , image 3 As shown, an alkaline battery positive electrode mixture granulation and screening device includes a casing 1 with a material inlet 11 and a material outlet 12, a rotating shaft 2 installed on the casing 1 through a bearing seat 6, and the rotating shaft 2 is fixed. And the granulation device 3 between the feed port 11 and the discharge port 12 in the casing 1, and the screen device 4 below the granulation device 3, the rotating shaft 2 includes the upper and lower shafts installed on the casing 1 Two sets of horizontal rotating shafts, the granulating device 3 includes a first granulating device 31 and a second granulating device 32 installed on the upper and lower two groups of horizontal rotating shafts 2 respectively, and the screen device 4 includes rings respectively The upper screen cloth 41 and the lower screen cloth 42 arranged on the radial outer periphery of the first granulation device 31 and the second granulation devi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com