Screw counter bore structure of plastic part

A technology of plastic parts and countersunk holes, applied in the direction of connecting components, furniture connections, mechanical equipment, etc., can solve the problems of affecting the overall appearance of the product, inconvenient operation of hand-held screws, etc., to simplify the installation work and installation efficiency, and reduce the effect of difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

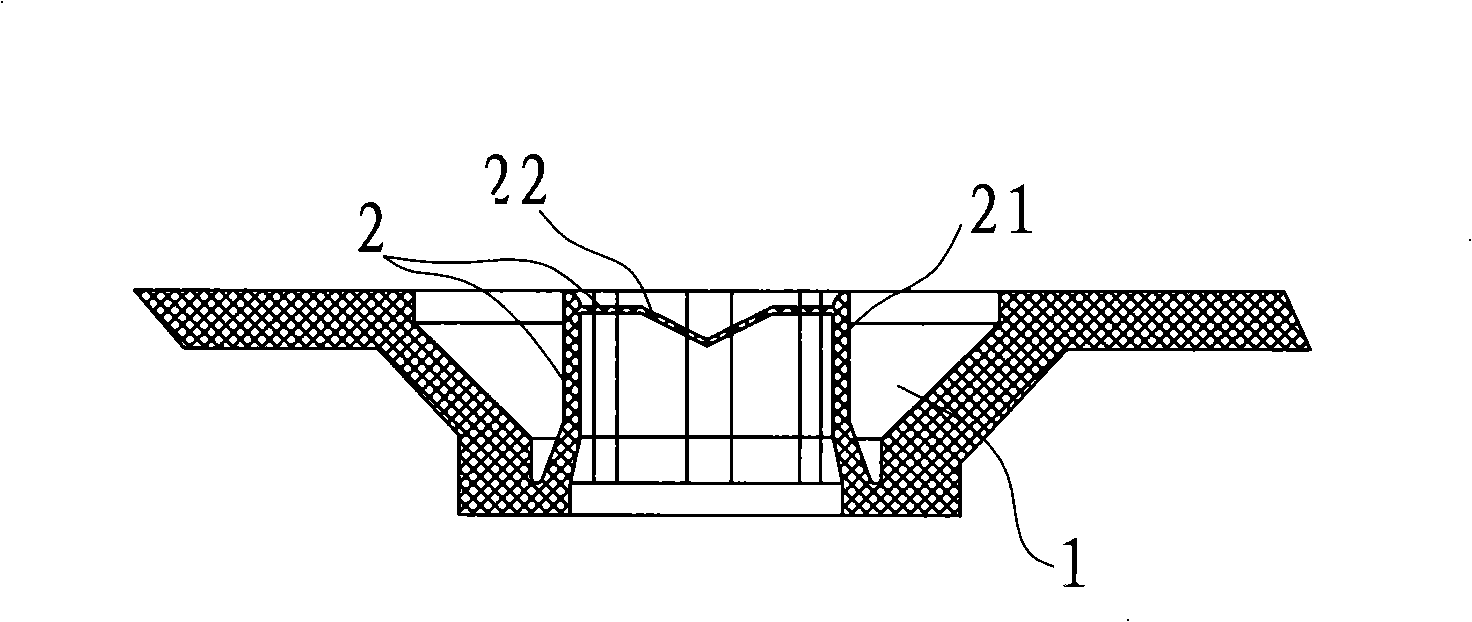

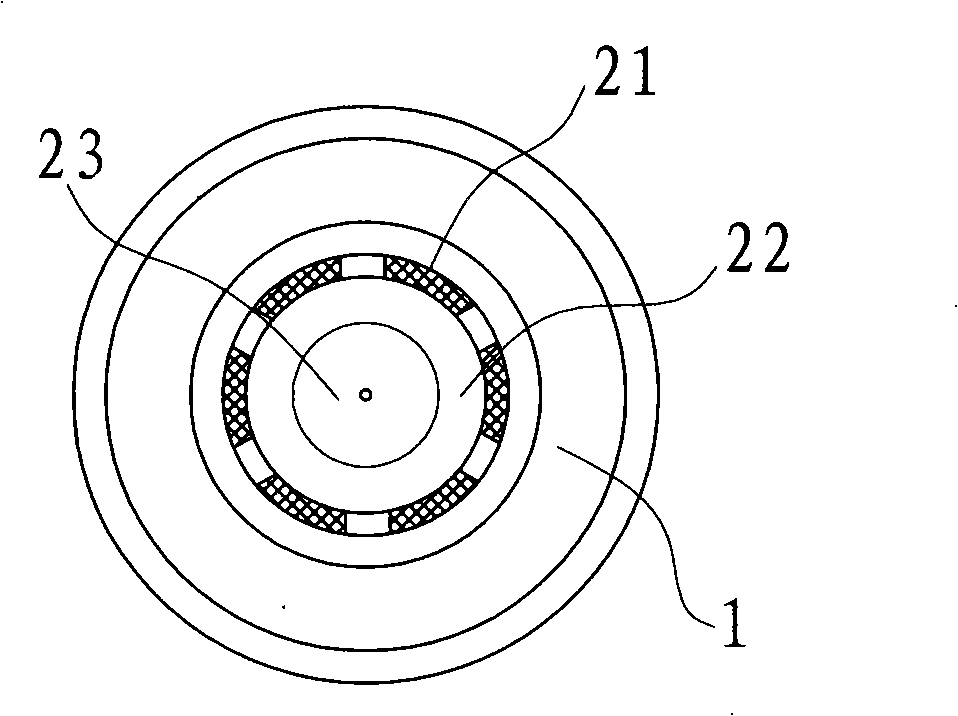

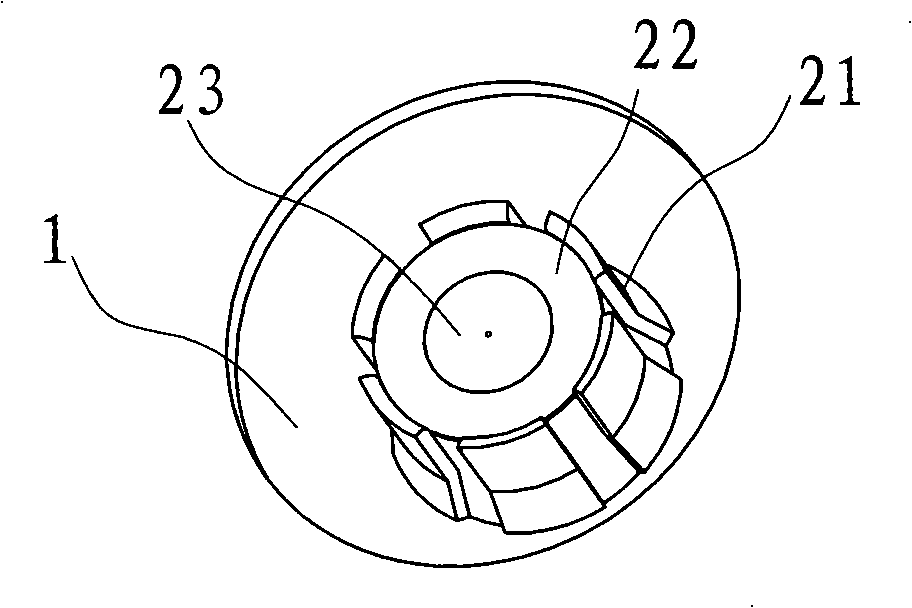

[0024] refer to Figure 1 to Figure 5 , the screw counterbore structure on the plastic part includes a counterbore 1, and the counterbore 1 is provided with a screw fixing part 2; Rib 21, the through hole surrounded by these elastic ribs 21 is compatible with the screw rod body, and the extension direction of these elastic ribs 21 is not necessarily a straight line, "く" shaped fold line and curve are also possible; and, in the elastic The inner wall of the rib 21 is also provided with a limiter 22 that is easily penetrated by screws, and the thickness of the limiter 22 is very thin, which is thinner than the elastic rib 21 and plastic parts. Usually, the limiter 22 is A thin sheet; and the elastic rib 21 and the limiting member 22 in the present invention are both made of plastic.

[0025] Before installing and fixing the plastic parts to the inner wall or bottom of the home, the screw is pressed against the sheet, and the screw penetrates the sheet and is stuck by the tube w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com