Building floor and producing method thereof

A technology for floor slabs and buildings, which is applied in the production of building slabs and building slabs. It can solve the problems of wood consumption, wind resistance, poor shock resistance, and many casualties, and achieve the effects of enhancing load-bearing shock resistance, prolonging life, and less disturbance to the people.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The building floor of the present invention and its production method will be further described in detail below in conjunction with the accompanying drawings.

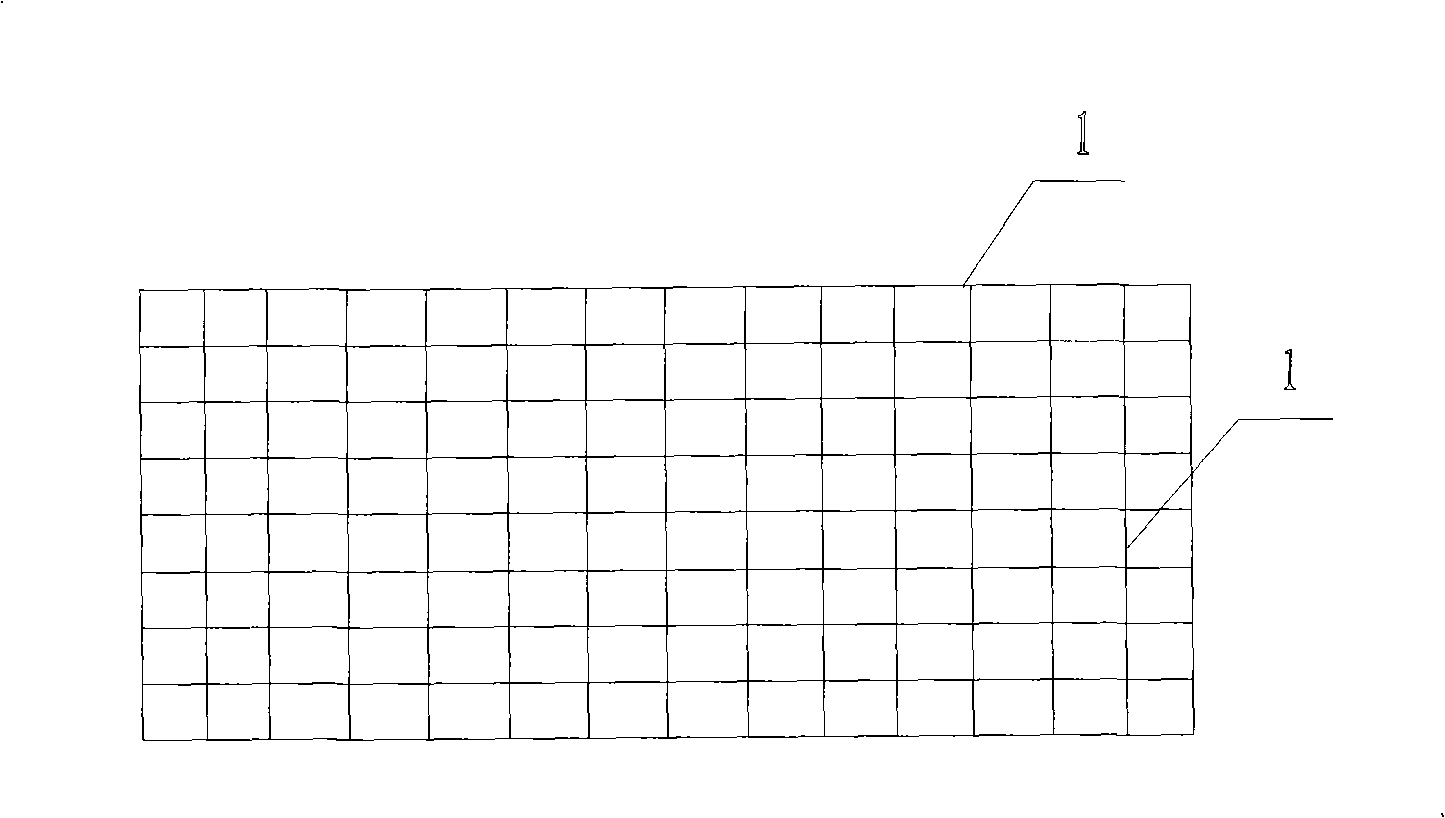

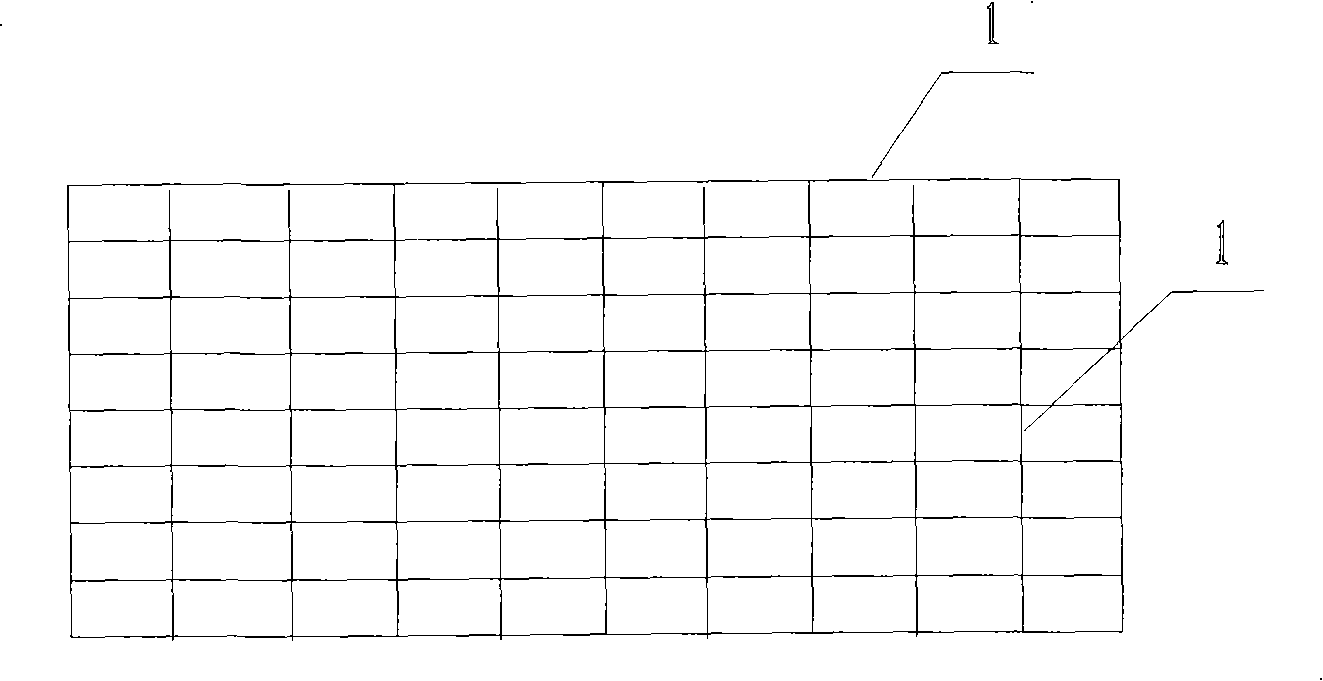

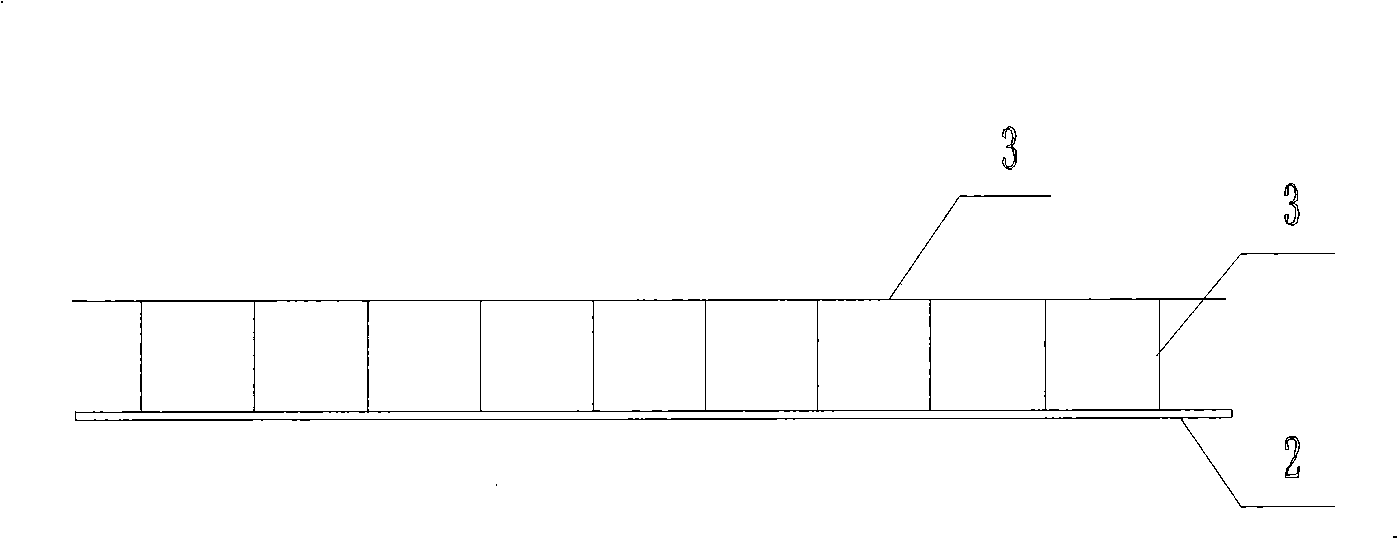

[0021] Such as Figure 1 to Figure 4 As shown, the floor slab of the building according to the present invention includes a steel mold ring beam and a main beam mold, a stainless steel keel bracket assembly is laid on the top of the mold, and a ceiling block is pasted in 1 grid of the keel bracket, and the ceiling block is supported by a steel pipe. The top, the ceiling surface is covered with ribs. The grid of the keel bracket is 60mm×60mm or 60mm×80mm, and the pre-embedded radial hook is welded on the top of the grid of the keel, and the visible surface of the keel is sprayed with color. The bottom main reinforcement on the ceiling surface adopts 10-12mm rebar 2, and the gluten adopts 6mm round steel 3. The method of producing a building slab comprises the following steps:

[0022] ① Lay the keel support as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com