Polytetrafluorethylene coating material for medical apparatus surface and coating method thereof

A technology of polytetrafluoroethylene and medical equipment, which is applied to the device, coating, pretreatment surface and other directions of coating liquid on the surface, which can solve the problem that interventional catheters and guide wires are difficult to adapt to the development direction of refinement, and limit polytetrafluoroethylene. The use of vinyl coating and the complex PTFE coating system can achieve the effect of short coating film formation time, low processing cost and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0022] Specific embodiment one: present embodiment is a kind of preparation method of PTFE lubricating hydrophobic coating, and it comprises the following steps successively:

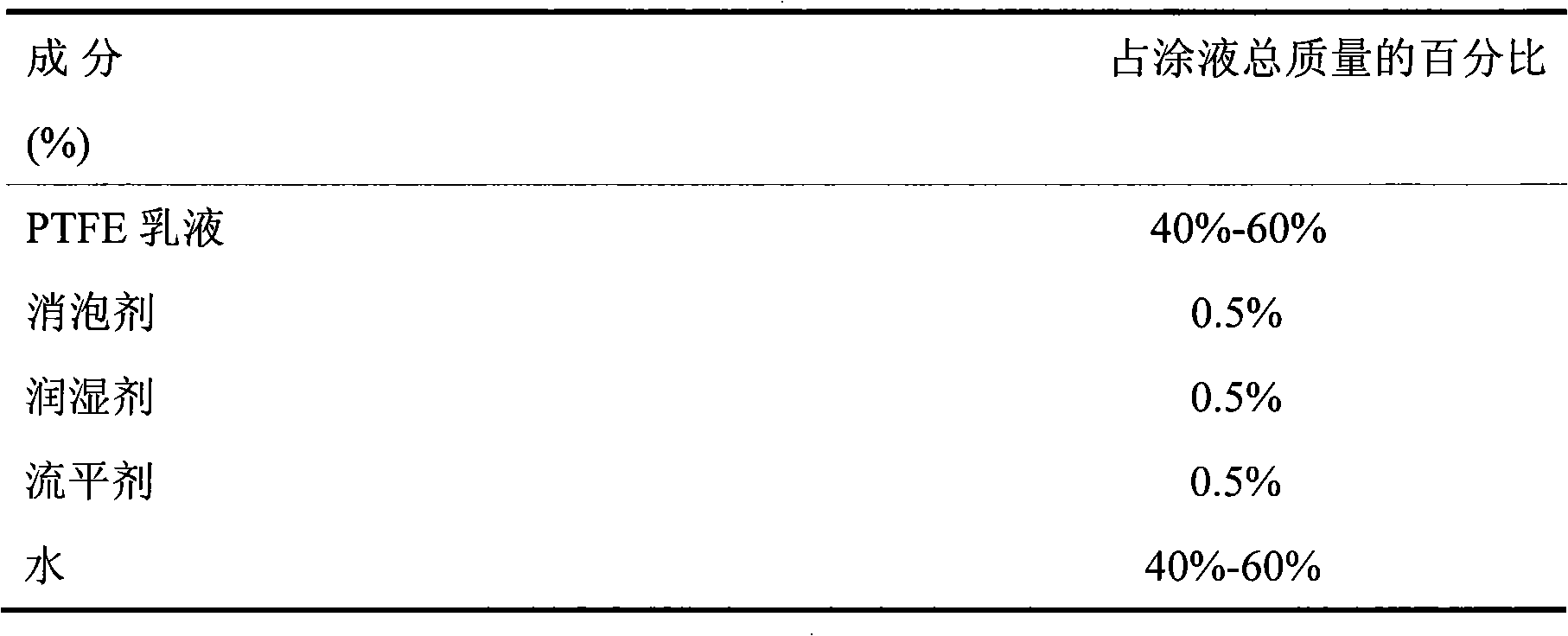

[0023] a. Prepare PTFE water-based paint according to the ratio of each composition in the paint shown in Table 2, and add defoamer, wetting agent, and leveling agent in sequence according to the order shown in the table; wherein, the defoamer is added in two times;

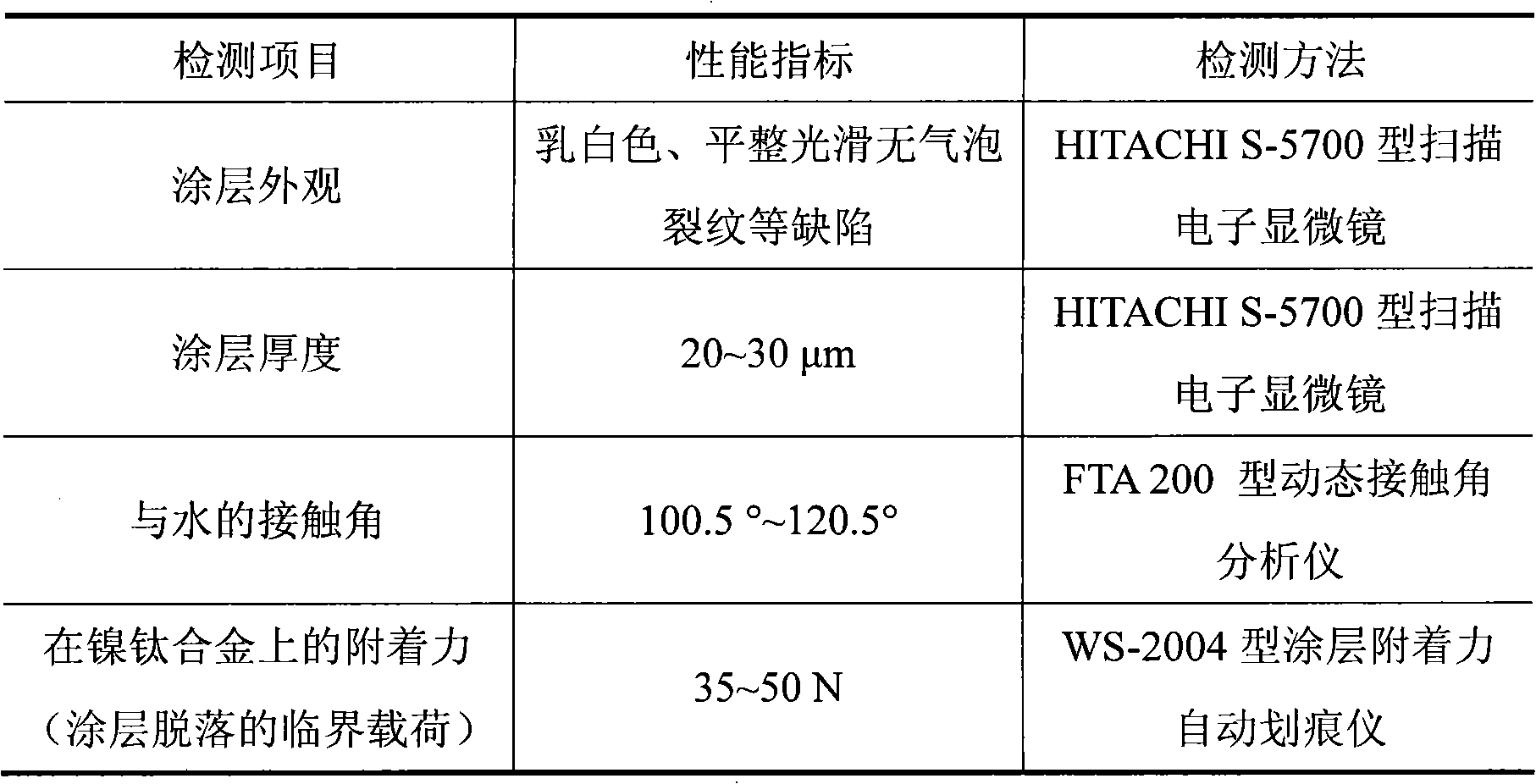

[0024] Table 2

[0025]

[0026] b. Stir the prepared PTFE water-based paint mechanically at low speed for a certain period of time, and place it for more than 24 hours for later use;

[0027] The PTFE emulsion described in this embodiment is all PTFE emulsions that can be used to prepare PTFE coatings for medical devices; the defoamers, wetting agents, and leveling agents described in this embodiment are all water-soluble.

specific Embodiment approach 2

[0028] Specific embodiment two: present embodiment is the coating method of PTFE water-based paint, and it comprises the following steps successively:

[0029] a. Immerse the medical device to be coated into the prepared PTFE water-based coating at a certain speed according to the required thickness.

[0030] b. At room temperature, the water in the water-based coating is volatilized until it is nearly dry, and then cured and sintered at a temperature range of 120-350 ° C for a certain period of time, that is, a PTFE lubricating hydrophobic coating is obtained on the surface of the medical device.

[0031] The medical devices described in this embodiment are generally medical catheters, guide wires, orthodontic wires; the coated parts are generally the surfaces of the above medical devices.

specific Embodiment approach 3

[0032] Embodiment 3: This embodiment is the specific process parameters for coating the surface of the guide wire whose proximal push rod section is nickel-titanium (Ni-Ti) alloy, and it includes the following steps in sequence.

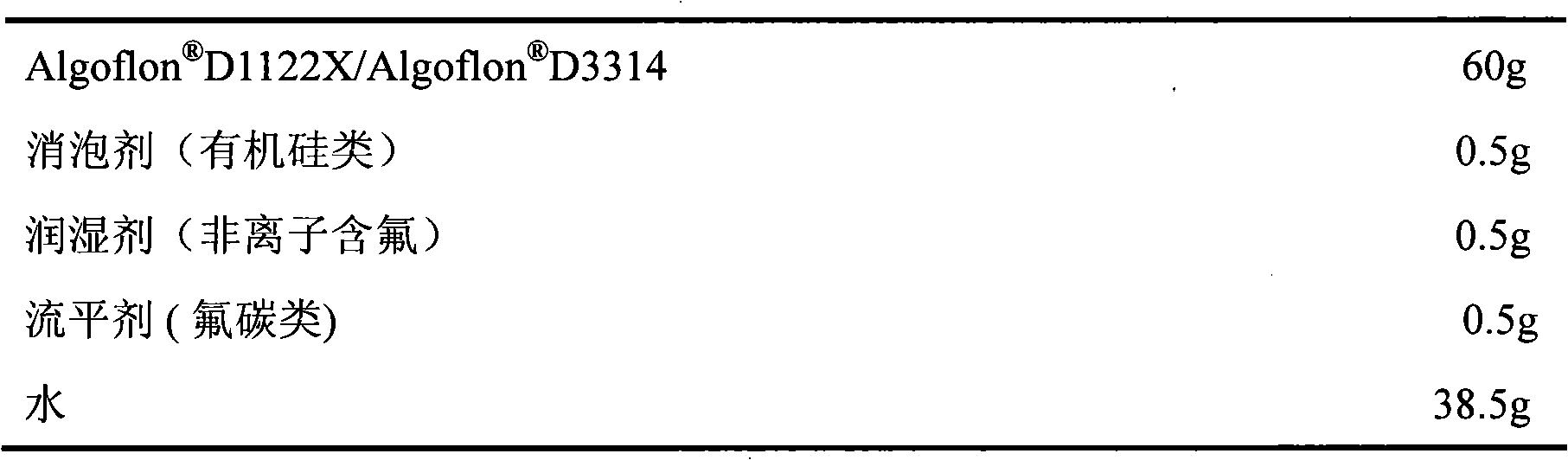

[0033] a. Prepare PTFE water-based paint according to the composition and proportion shown in Table 3. Its preparation process is the same as the specific embodiment one.

[0034] table 3

[0035]

[0036] b. Stir the prepared PTFE water-based paint mechanically at low speed for 2 hours, and then place it for 24 hours for later use.

[0037] c. After degreasing and degreasing the near-end pushing rod section of the Ni-Ti alloy guide wire, clean it thoroughly and dry it at room temperature.

[0038] d. Immerse the proximal pushing section of the Ni-Ti alloy guide wire into the prepared PTFE water-based paint, pull it out at a constant speed of 5cm / sec, and let it dry at room temperature.

[0039] e. Curing and sintering at a temperature of 350° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com