Strawberry preserving composite packaging film and preparation method thereof

A composite packaging film and strawberry technology, applied in the direction of protecting fruits/vegetables with a coating protective layer, can solve the problems of no practical application prospect, time-consuming Bacillus subtilis, complicated raw materials, etc., to prolong sales time and film-forming time Fast, easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

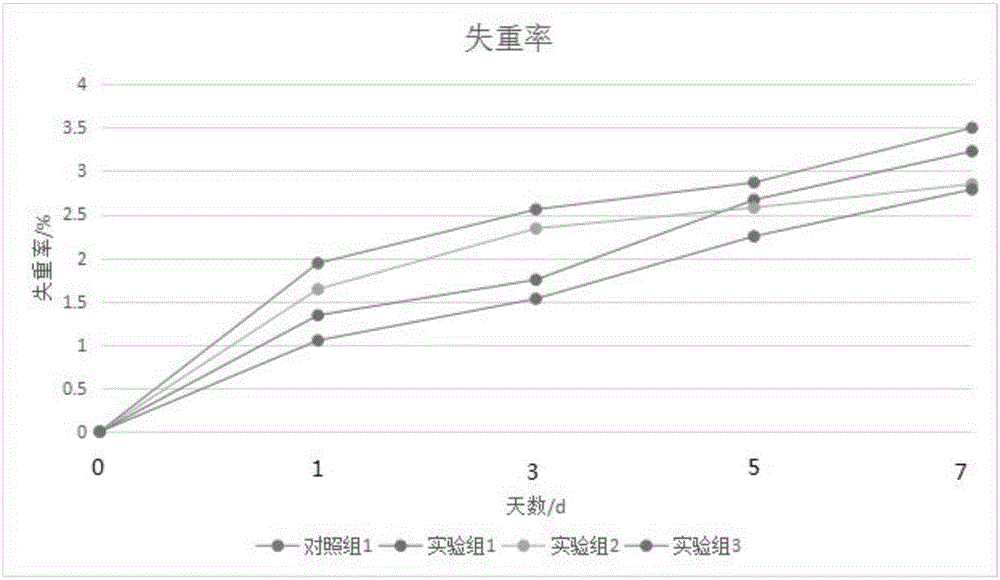

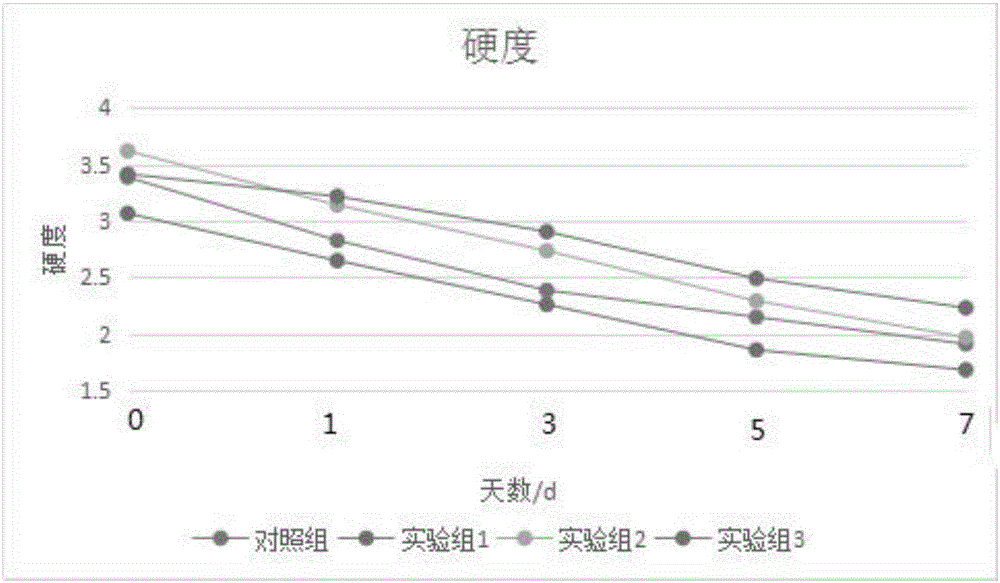

Embodiment 1

[0031] Dissolve 3g of chitosan in 97ml of 90% acetic acid solution, stir magnetically until completely dissolved, add 60g of cornstarch into 940ml of distilled water, gelatinize at 80°C, and mix the gelatinized starch and the dissolved chitosan solution according to Mixing at a mass ratio of 2:1, adding 0.2mg / kg of essential oil, adding 20mg / kg of glycerin as a plasticizer, stirring and mixing, ultrasonic defoaming, to obtain a spinning solution; using an electrospinning spinning device Spinning, the specification of the electrospinning syringe is 50ml, the needle specification is flat, No. 7 needle, the electric field strength is 2.0kv / cm, and the distance is 7-10cm. After the completion, the electrospinning nano-membrane is obtained.

Embodiment 2

[0033] Dissolve 1g of chitosan in 99g of 1% acetic acid solution, magnetically stir until completely dissolved, add 60g of cornstarch to 940ml of distilled water, gelatinize at 80°C, and mix the gelatinized starch and the dissolved chitosan solution according to the mass Mix at a ratio of 1:1, add 0.2mg / kg of essential oil, add 20mg / kg of glycerin as a plasticizer, stir and mix, ultrasonic defoaming, the pattern is a square Teflon pattern with a side length of 5cm A patterned film was prepared on the patterned template by tape casting, and the drying temperature was controlled at 50°C.

Embodiment 3

[0035] Take out the patterned film after drying in Example 2, place it on the front end of the receiving plate device for electrospinning, and use the spinning solution to carry out electrospinning. The specification of the electrospinning syringe is 50ml, and the needle specification is flat, No. , the electric field strength is 2.0Kv / cm, the distance is 7-10cm, and the spinning is completed, that is, the composite packaging film of electrospun nano-film and sheet film is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com