Fibers made from copolymers of propylene/alpha-olefins

A technology of interpolymer, propylene, applied in the field of fibers made of propylene/α-olefin interpolymer, which can solve problems such as lack of chlorine resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

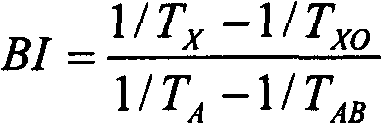

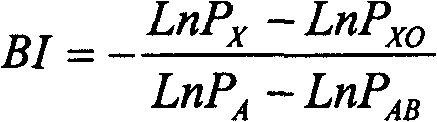

[0109] where TX is the preparative ATREF elution temperature (preferably expressed in Kelvin) of the i-th fraction, P X is the propylene mole fraction of the i fraction, which can be determined by NMR or IR as described above. P AB is the propylene mole fraction of the overall propylene / α-olefin interpolymer (before fractionation), which can also be determined by NMR or IR. T A and P A is the ATREF elution temperature and propylene mole fraction of the pure "hard segment" (which refers to the crystalline segment of the interpolymer). As a first-order approximation, if the actual value of the "hard segment" cannot be obtained, T A and P A Values are set as those for polypropylene homopolymer.

[0110] T AB for the same composition and with P AB ATREF temperature of random copolymers of propylene mole fraction. T AB It can be calculated by the following equation:

[0111] LnP AB =α / T AB +β

[0112] where α and β are two constants that can be determined by a calib...

Embodiment 1

[0239] A propylene / ethylene block copolymer having a composition of about 12% by weight ethylene and about 88% by weight propylene (soft segment) was melt spun into fine fibers (less than about 4 denier / filament) using a spunbond unit. ), under the conditions of ASTM D 1238, 230°C / 2.16 kg, the melt flow rate (MFR) was measured to be about 25g / 10min, and about 0.877g / cm 3 The overall density, with an estimated hard segment content of about 30% and a soft segment content of about 70%. The melt spinning temperature is about 245° C., the throughput is about 0.5 ghm (gram / minute / hole), and the fiber in the melt is drawn from a spinneret diameter of about 600 microns to each filament from Fiber diameters of about 2 to less than about 4 denier. The resulting nonwoven fabric is then thermally bonded at a temperature of about 200 to 220° C. and a pressure sufficient to point bond the fibers. The mechanical properties of the individual fibers were determined and had a tensile strength...

Embodiment 2

[0241]The propylene / ethylene block copolymer was melt spun into about 40 denier fibers (monofilaments) using a spunbond unit, the copolymer having about 12 wt. % ethylene and about 88 wt. Under the condition of one kilogram, its melt flow rate (MFR) was determined to be about 9g / 10min, and about 0.875g / cm 3 , with an estimated hard segment content of about 30% and a soft segment content of about 70%. The melt spinning temperature was about 245°C, and the fiber was drawn in the melt from a spinneret diameter of about 800 microns to a fiber diameter equivalent to 40 denier at a take-up speed of about 550 m / min. The mechanical properties of this fiber in the form of a spool (before crosslinking) were determined and it had a tensile strength of about 1 to 1.5 g / denier, an elongation at break of 450 to 500%, a permanent set of about 40 to 60% ( 5 cycles at 300% strain, BISFA method) and a melting point of about 160°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com