Electric power steering device

A technology of electric power steering and steering column, which is applied in the direction of electric steering mechanism, electromechanical device, steering column, etc. It can solve the problems of adding electric power steering device, poor connector connection workability, and insufficient heat dissipation effect, etc. Heat capacity, the effect of improving the heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Embodiments of the present invention will be described below with reference to the drawings.

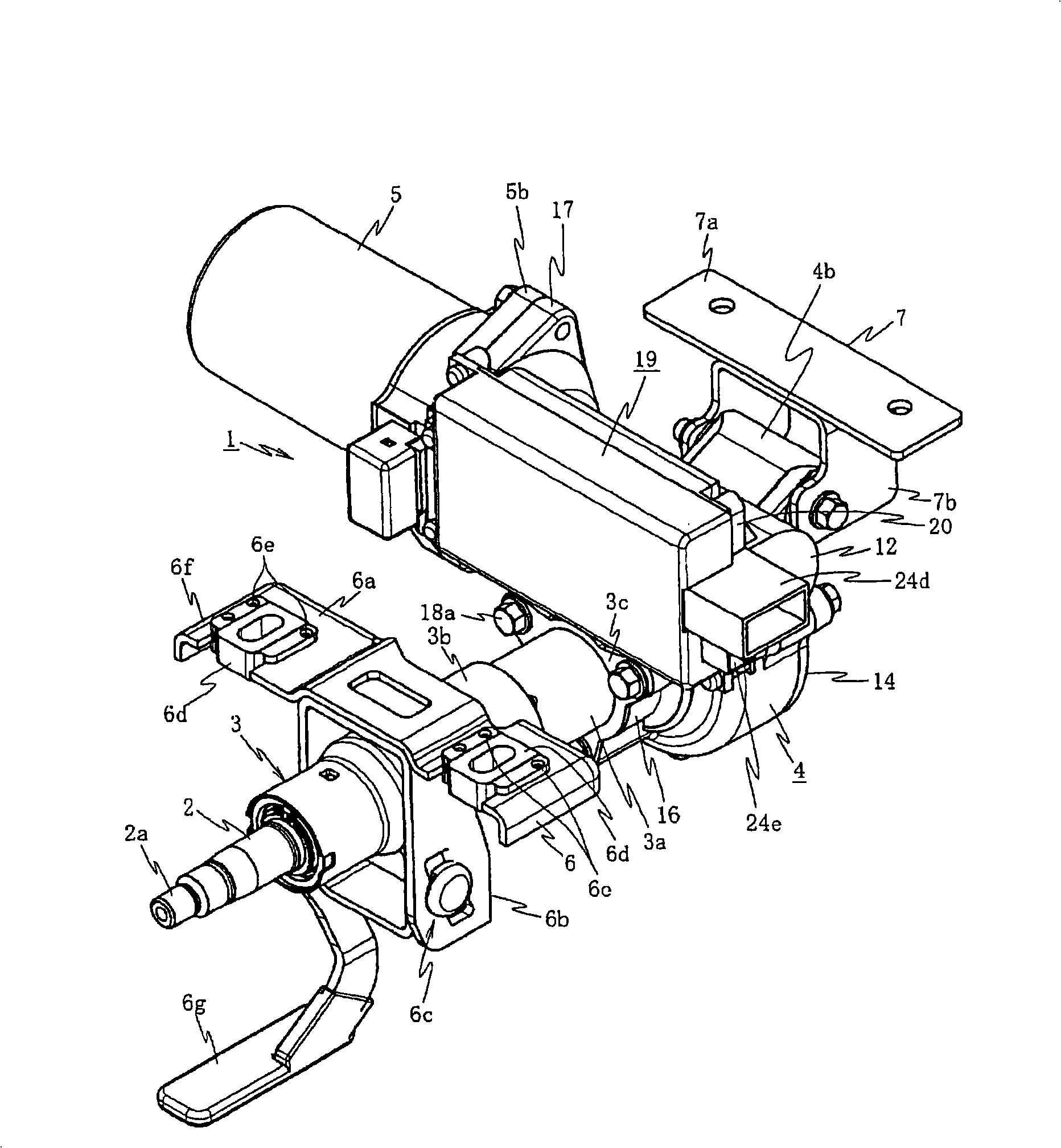

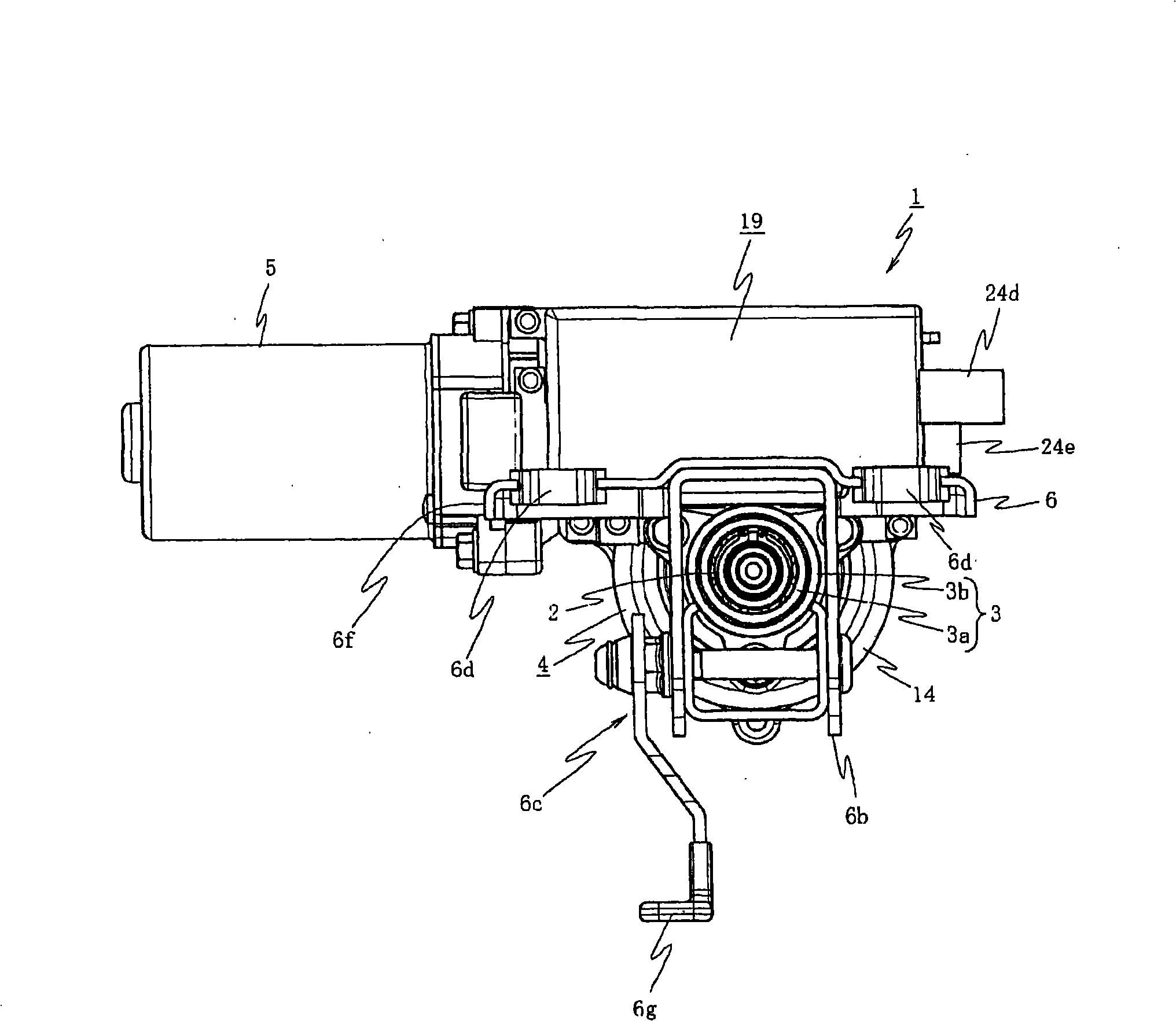

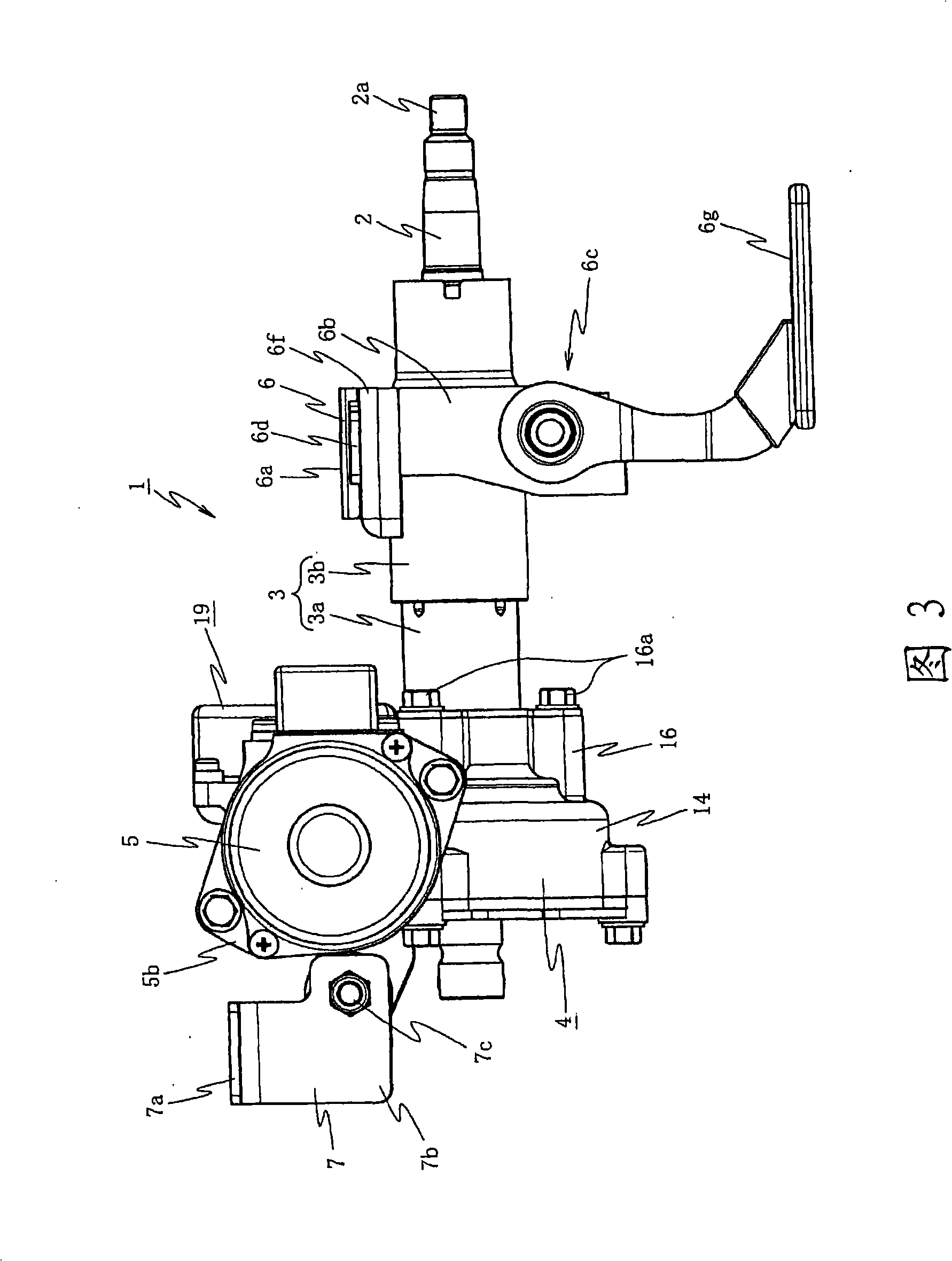

[0065] figure 1 It is a perspective view of an example when an embodiment of the present invention is applied to a right-hand steering vehicle, figure 2 is the front view, Figure 3 is the left side view, Figure 4 is a top view, Figure 5 and Figure 6 It is an exploded perspective view of the main part.

[0066] figure 1 Among them, 1 is a column type electric power steering device, a steering shaft 2 is rotatably built in a steering column 3, and the steering shaft 2 has a steering wheel assembly part 2a for assembling a steering wheel (not shown). 3 is connected to a reduction gear box 4, and an electric motor 5 constituted by a brush motor is disposed on the reduction gear box 4, and the axial direction of the electric motor 5 extends in a direction perpendicular to the axial direction of the steering column 3.

[0067] Here, the steering column 3 adopts a double-tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com