Transmission shaft structure

A technology for transmission shafts and transmission parts, applied in the field of transmission shafts, can solve the problems of inability to locate in the middle position, slow actuation speed, difficult replacement of components and maintenance, etc., to reduce occupied space, ensure concentricity, and be easy to assemble Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

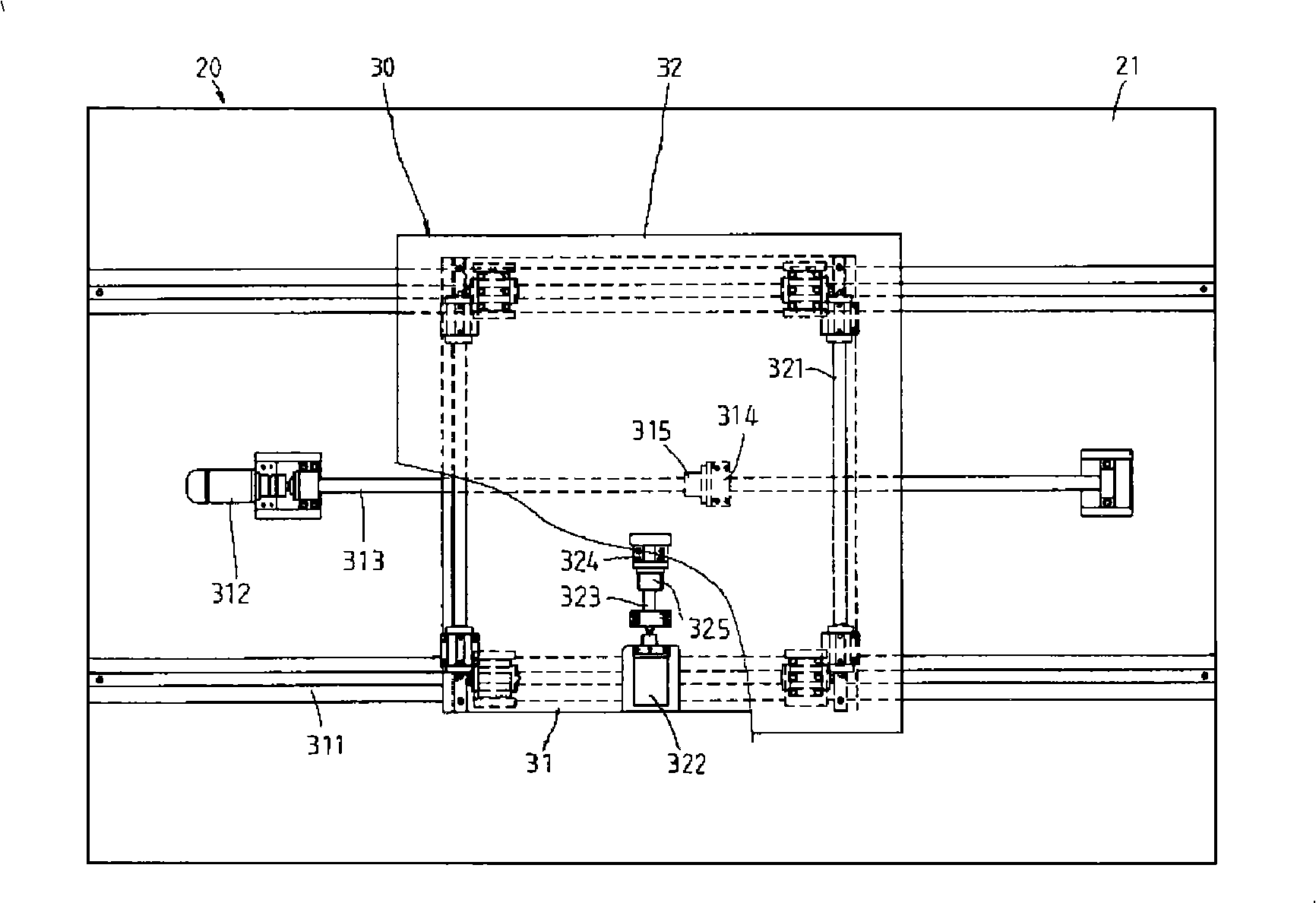

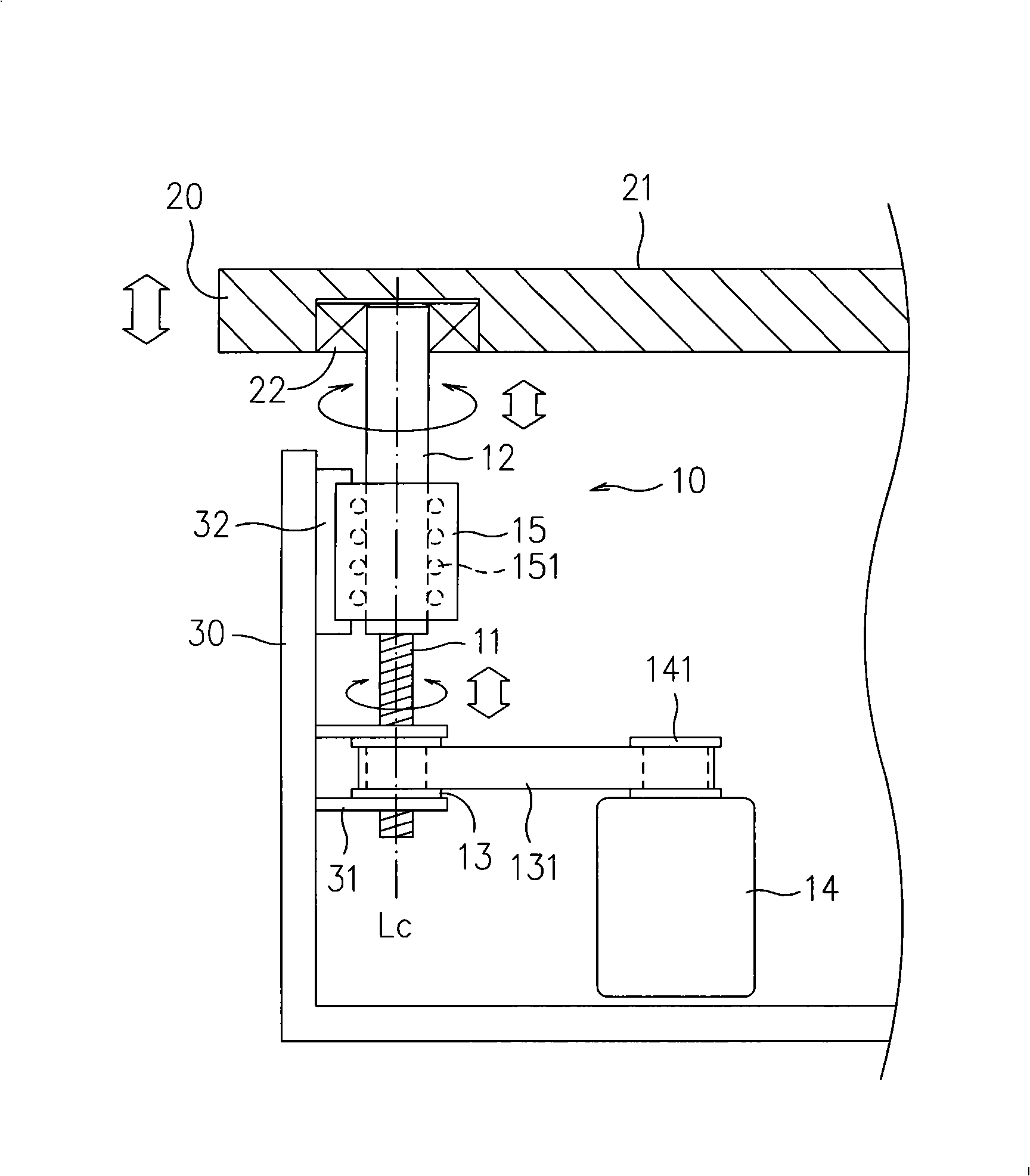

[0034] see image 3 As shown, the transmission shaft structure 10 proposed by the present invention mainly includes a screw rod 11 and a slider 12, the screw rod 11 is arranged in a vertical direction, and the slider 12 is integrally formed on the coaxial line Lc The top of the screw 11 and the top of the slider 12 are pivotally connected to a platform 20, the platform 20 has a bearing surface 21 for carrying objects, the screw 11, the slider 12 The axis Lc is perpendicular to the bearing surface 21, that is, the bearing surface 21 is set horizontally; secondly, a ball nut 13 is screwed outside the screw rod 11, and the ball nut 13 It is positioned on the machine platform 30 by the positioning piece 31, and is connected with the power output shaft 141 of a driving motor 14 through a belt 131. As is well known to those skilled in the art, the belt 131 can also be a chain or other Transmission parts with the same transmission function.

[0035] When the drive motor 14 rotates,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com