Faucet built-in type inspection shaft

A built-in, inspection well technology, applied in water conservancy projects, artificial islands, underwater structures, etc., can solve the problems of difficult injection molding production, increased well block volume, large mold cost, etc. Small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

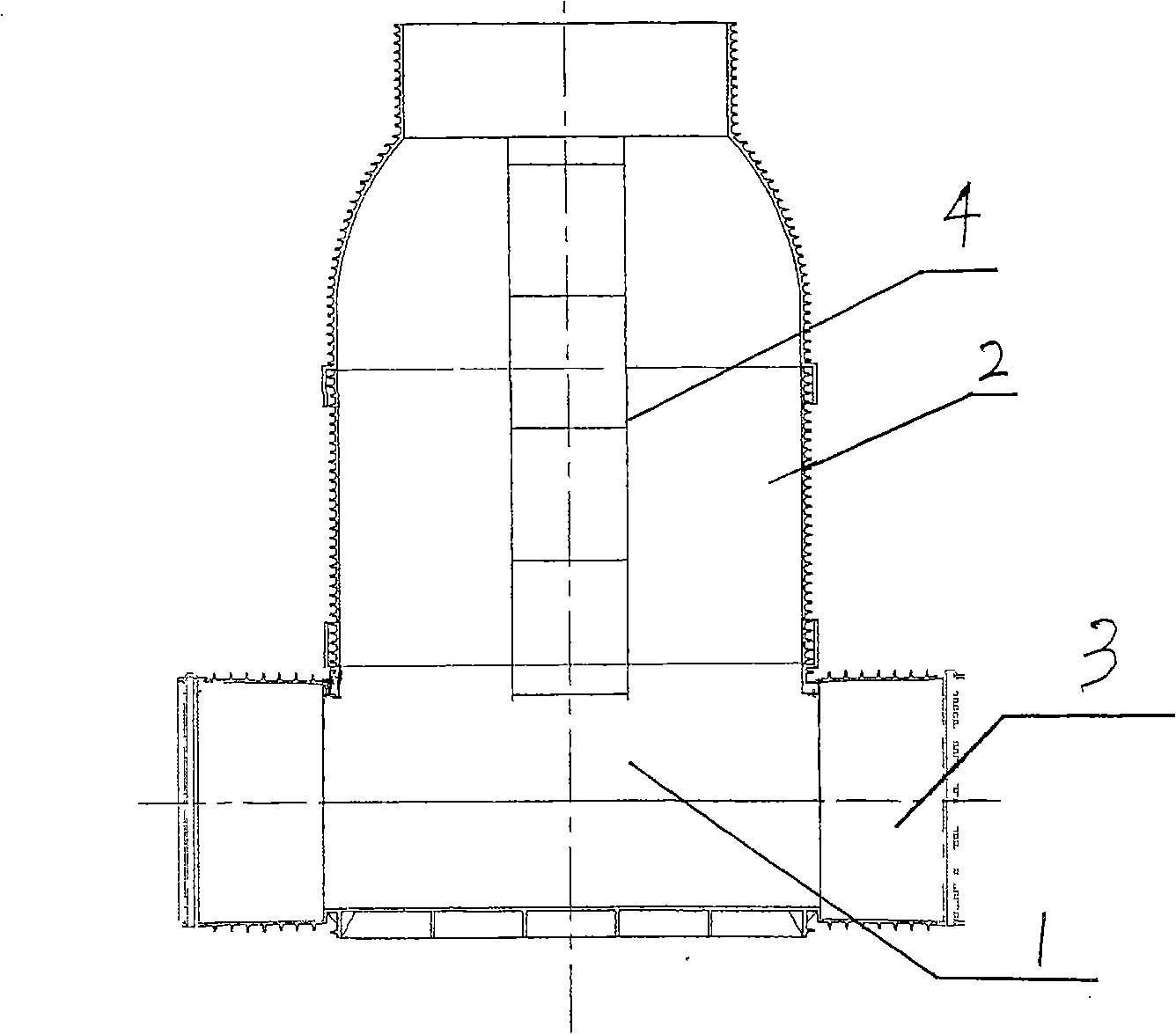

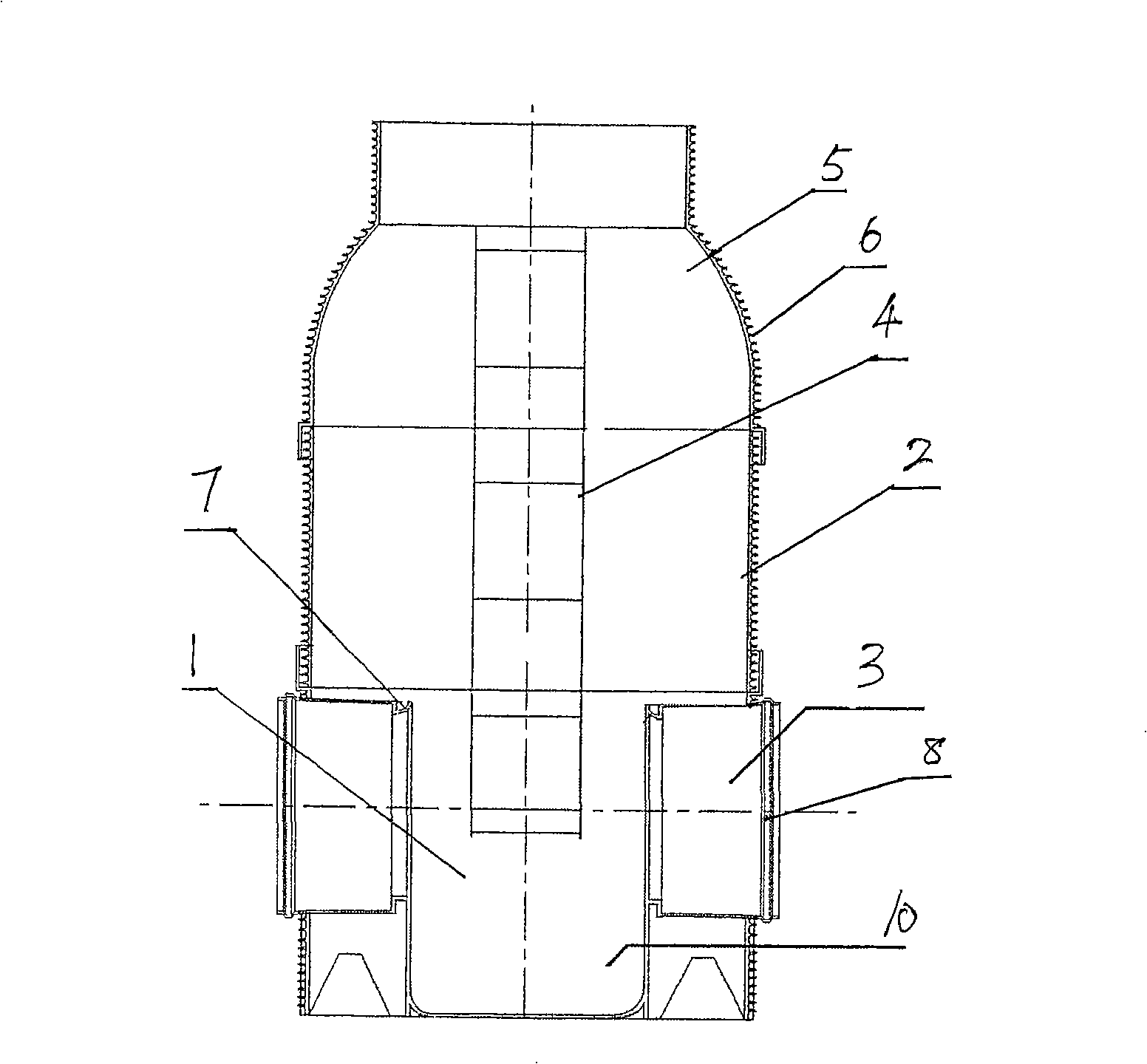

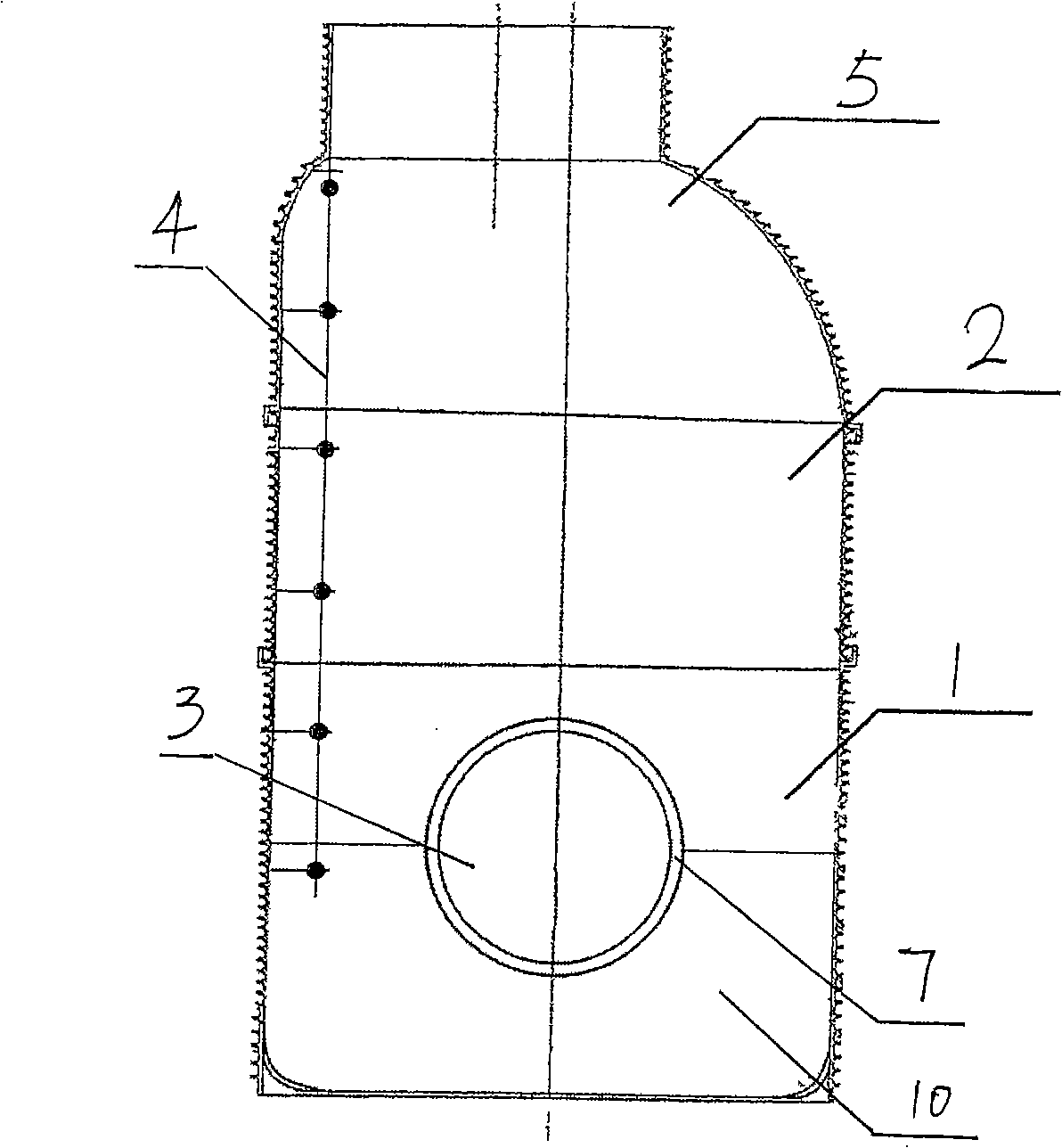

[0024] Such as figure 2 Shown is a first embodiment of the invention. An inspection well with a built-in socket, including a well base 1 and a well shaft 2, the well shaft 2 is installed on the well base 1, the well base 1 has a pipe socket 3 connected to the buried pipeline, and the pipe socket 3 is built into the well base 1 , the manhole 5 of closing type can be set on the shaft 2. Ladder 4 is set in the well. Because the pipe socket 3 is built in the well base 1 , the diameter of the entire well base 1 is only slightly larger than the diameter of the wellbore 2 . Compared with the well block 1 of the existing structure, the volume can be greatly reduced. The well base 1, the shaft 2 and the manhole 5 on the shaft 1 are of a structural wall type with reinforcing ribs 6 on the outer wall. There is a circular arc transition guide 7 on the edge of the end of the pipe socket 3 . In order to make the connection between the pipe socket 3 and the pipe reliable and prevent le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com