Preparation of m-xylene diamine epoxide resin

A technology of m-xylylenediamine epoxy resin and m-xylylenediamine, which is applied in the field of preparation of shrinkage amine epoxy resin, can solve the problems of unseen preparation method and complex production process, and achieve high epoxy value, The effect of low viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

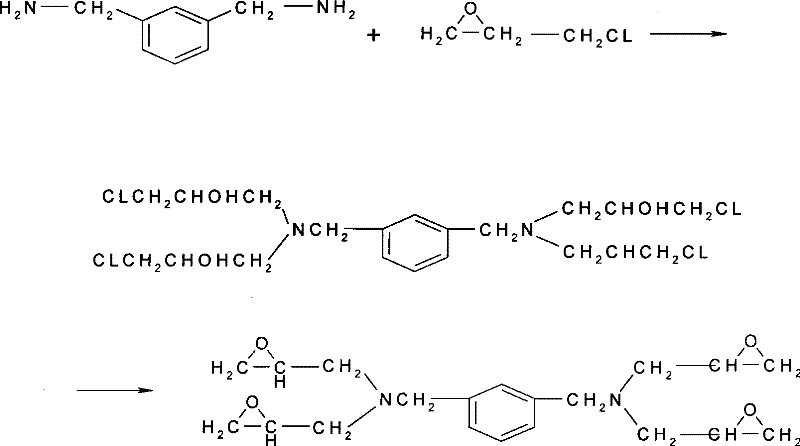

Method used

Image

Examples

Embodiment 1

[0025] Add 300g of m-xylylenediamine and 0.3g of benzyltriethylammonium chloride into the reactor, mix well, add 60g of epichlorohydrin dropwise at 35°C for 1 hour, and continue etherification at 35°C for 6 hour, reclaim the remaining m-xylylenediamine (water can be added appropriately in the recovery process), reclaim the terminal temperature 100 DEG C, pressure-0.08Mpa, reclaim complete, drip concentration at 50 DEG C and be the sodium hydroxide solution 175g of 15%, 1 Add 1 hour, react at 70°C for 5 hours, add 600g toluene to dissolve the product at 50°C for 0.5 hour, separate the m-xylylenediamine epoxy resin solution, wash the resin solution with hot water at 50°C until it is neutral, and remove the solvent , the final temperature is 120°C, and the pressure is -0.08Mpa.

[0026] Product index: epoxy value 1Eq / 100g, viscosity 20000mpa.s.

Embodiment 2

[0028] Add 300g of m-xylylenediamine and 900g of benzene into the reactor, mix well, add 840g of epichlorohydrin, etherify at 80°C for 1.5 hours, then add 950g of 40% sodium hydroxide dropwise, and close the ring at 50°C React for 3 hours, add 600g of benzene and dissolve at 40°C for 0.5 hours, wash the resin solution with hot water at 40°C until it is neutral, and remove the solvent. The final temperature is 100°C and the pressure is -0.09Mpa.

[0029] Product index: epoxy value 0.94Eq / 100g, viscosity 16500mpa.s.

Embodiment 3

[0031] Add 300g of m-xylylenediamine and 900g of methyl isobutyl ketone into the reactor, mix well, add 840g of epichlorohydrin, etherify at 50°C for 3 hours, then add dropwise 40% sodium hydroxide 950g , ring-closing reaction at 50°C for 3 hours, add 600g of methyl isobutyl ketone and dissolve at 70°C for 0.5 hour, wash the resin solution with hot water at 70°C until neutral, remove solvent, final temperature 100°C, pressure -0.09Mpa .

[0032] Product index: epoxy value 0.95Eq / 100g, viscosity 20000mpa.s.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com