A kind of hypromellose enteric-coated empty capsule with potassium salt and sodium salt gel

A technology of hypromellose and hollow capsules is applied in the directions of capsule delivery, medical preparations with non-active ingredients, pharmaceutical formulations, etc. The effect of low water volume and high medication compliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

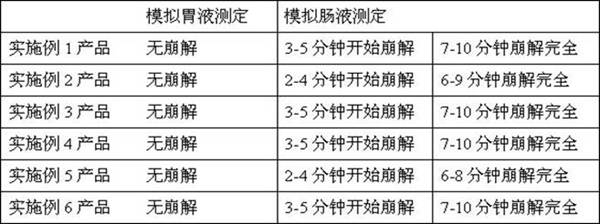

Examples

Embodiment 1

[0023](1) Take 50 kg of hypromellose and put it into 120L of purified water at a temperature of 85°C, stir and mix quickly for 13 minutes, and then keep it at a temperature of 82°C for 60 minutes to obtain a hypromellose solution.

[0024](2) Take 270g of gellan gum and stir and swell it in 120L of purified water at a temperature of 40°C, then heat to 85°C and keep it at rest for 55 minutes to obtain a gellan gum swelling liquid.

[0025]⑶ The gellan gum swelling liquid was added to the hypromellose solution at a temperature 3°C higher than the temperature of the hypromellose solution. When adding, the hypromellose solution and the gellan gum swelling liquid were added to the same Pour into the mixing kettle at the same speed and start stirring when pouring. After pouring, continue to stir and mix for 13 minutes, and then cool to 75°C to obtain a hypromellose gel solution.

[0026]⑷ Take 270g of potassium chloride and add it to the hypromellose gel solution, stir at 900 rpm for 2 minutes, th...

Embodiment 2

[0035](1) Take 50 kg of hypromellose and put it into 125L of purified water at a temperature of 92°C, stir and mix quickly for 15 minutes, and then keep it at a temperature of 85°C and let it stand for 75 minutes to obtain a hypromellose solution.

[0036](2) Take 357g of gellan gum, stir and swell it in 125L of purified water at a temperature of 42.5°C, then heat to 90°C and keep it at rest for 60 minutes to obtain a gellan gum swelling liquid.

[0037]⑶ The gellan gum swelling liquid was added to the hypromellose solution at a temperature 4°C higher than the temperature of the hypromellose solution, and the hypromellose solution and the gellan gum swelling liquid were added to the same Pour into the mixing tank at the same speed and start stirring when pouring. After pouring, continue to stir and mix for 15 minutes, and then cool to 80°C to obtain a hypromellose gel solution.

[0038]⑷ Add 286 g of potassium chloride to the hypromellose gel solution, stir for 2.5 min at 1000 rpm, then vacu...

Embodiment 3

[0046](1) Take 50 kg of hypromellose and put it into 130L of purified water at a temperature of 98°C, stir and mix quickly for 17 minutes, and then keep it at a temperature of 92°C for 90 minutes to obtain a hypromellose solution.

[0047](2) Take 405g of gellan gum and stir and swell it in 130L of purified water at a temperature of 45°C, then heat to 95°C and keep it for 65 minutes to obtain a gellan gum swelling liquid.

[0048]⑶ The gellan gum swelling liquid is added to the hypromellose solution at a temperature 5°C higher than the temperature of the hypromellose solution, and the hypromellose solution and the gellan gum swelling liquid are added to the same Pour into the mixing kettle at the same speed and start stirring when pouring. After pouring, continue to stir and mix for 17 minutes, and then cool to 85°C to obtain a hypromellose gel solution.

[0049]⑷ Add 310 g of potassium chloride to the hypromellose gel solution, stir at 1100 rpm for 3 minutes, then vacuum and degas for 11 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com