Filming flow type polyacrylacid ester soap-free emulsion, synthetic process and use thereof in printing ink

A technology of polyacrylate and soap-free emulsion, which can be used in inks, applications, household utensils, etc. It can solve the problems of short development time and foreign exchange consumption, and achieve the effects of high transparency, good weather resistance, and small chroma value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

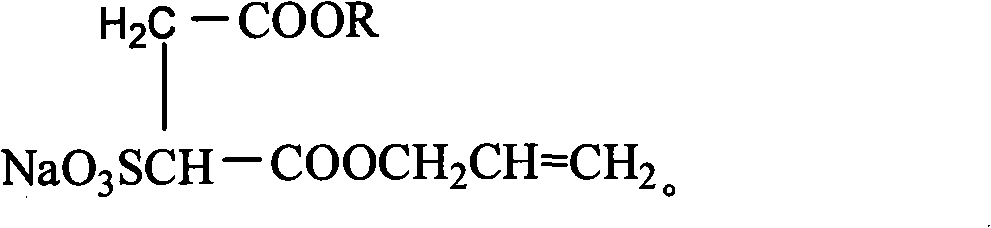

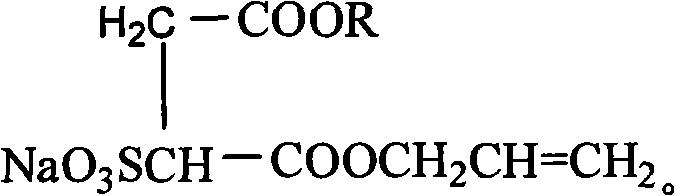

Method used

Image

Examples

Embodiment 1

[0056] In a 3-liter four-necked round-bottom flask with paddle stirrer, thermocouple and condenser, add 323.5 grams of deionized water, 4 grams of JS-2 (polymerizable emulsifier) emulsifier, and use 10 grams of deionized 2 grams of ammonium persulfate dissolved in water make the first mixture; in another round-bottomed flask with stirring (stirring is opened), add 120 gram deionized water, 6 gram JS-2 emulsifier, stir for 5 minutes, Then, in the process of constant stirring, 100 grams of methyl methacrylate, 20 grams of styrene, 16 grams of methacrylic acid, 164 grams of butyl acrylate, 100 grams of isooctyl acrylate, 50 grams of RHODOLINE211 (sodium polyacrylate 43% solution), n-dodecyl mercaptan 20 grams, make pre-emulsion A; Add 1 gram of ammonium persulfate that 50 grams of deionized water dissolves in the third round bottom flask again, make initiator solution A ;The first mixture is warmed up to 85°C, and within 90 minutes, the pre-emulsion A is added dropwise to the f...

Embodiment 2

[0058] Embodiment 2 The process is the same as that of Embodiment 1, except that the emulsifier JS-2 is changed to SVS-25 to prepare a film-forming emulsion B with a viscosity of 1000 cps, a pH value of 8.6, and a solid content of 45%.

Embodiment 3

[0060] Johnson 617 was selected as a reference substance, and the application test research in water-based ink was carried out, and two kinds of water-based flexographic paper inks, red and blue, were prepared.

[0061] The red water-based ink formula is: 30 grams of red water-based ink base ink, 20 grams of non-film-forming emulsion Johnson631, 45 grams of film-forming emulsion Johnson617, and 5 grams of W2F polyethylene wax.

[0062] The blue water-based ink formula is: 40 grams of blue water-based ink base ink, 100 grams of non-film-forming emulsion Johnson631, 45 grams of film-forming emulsion Johnson617, and 5 grams of W2F polyethylene wax.

[0063] The film-forming emulsion A prepared by the present invention was used instead of Johnson617 to obtain a comparative sample.

[0064] The product performance comparison is as follows:

[0065] Table 3 Performance comparison of water-based ink products prepared by different film-forming emulsions

[0066]

[0067] As can b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com